3D Printing Industry is hosting an event to recognize the leading enterprises, groups, and individuals, in the additive manufacturing sector. The 3D Printing Industry Awards are voted on by our readers and the winners will each receive a metal 3D printed trophy at our awards ceremony in central London on 20th May.

So far we have looked at the shortlists for best enterprise 3D printer, the best personal 3D printer manufacturer, the enterprise additive manufacturing OEM of the year, and best 3D printing software of the year. Additionally, you can also read our most recent articles on the nominations for best 3D scanner of the year, best 3D printing startup, and the most popular nominations that although they did not make the shortlist, are still active in the 3D printing industry.

This article will review the 3D printing innovations that have been nominated for a 3D Printing Industry Award.

The 3D Printing Industry Awards 2017: Innovation of the year

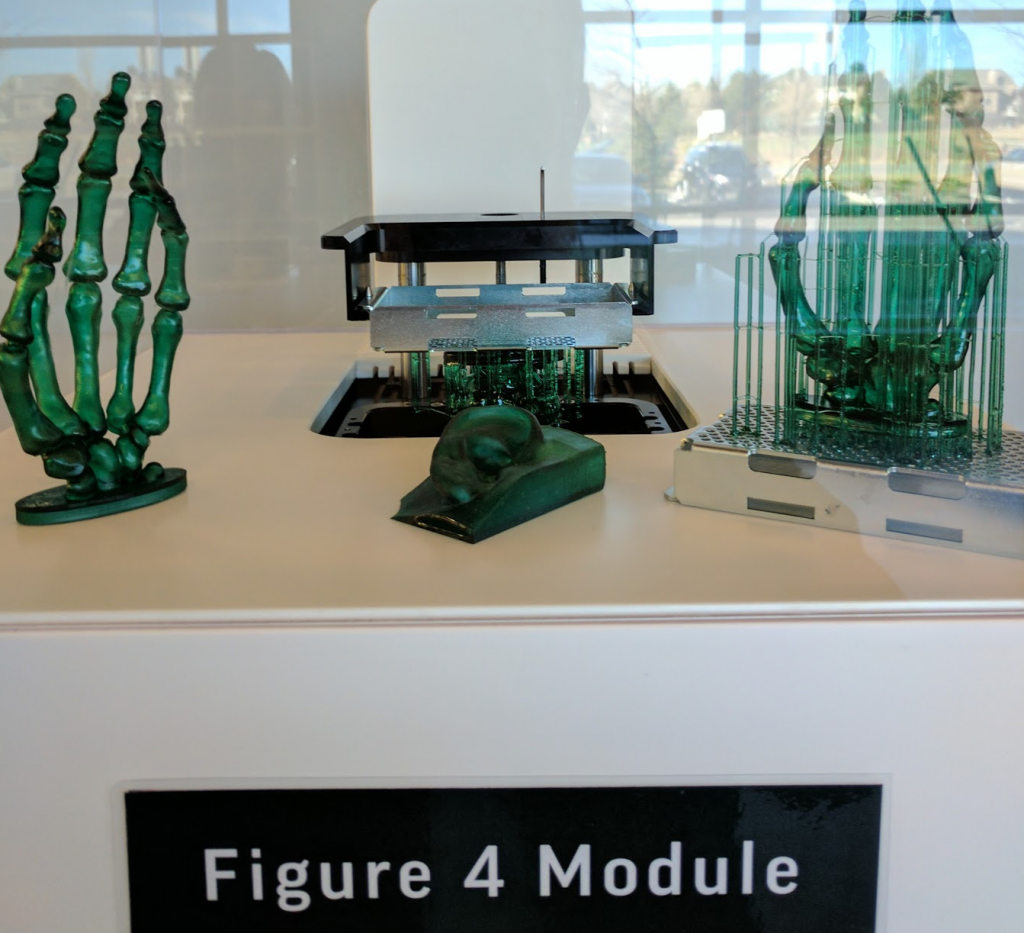

3D Systems Figure 4 technology

First unveiled in April 2016, 3D Systems’ Figure 4 technology is a rapid 3D printing method configured for mass production.

The Figure 4 3D printing system is named after one the diagrams in Chuck Hulls original patent applications. Working with a combination of resin materials, robot arms and a series of stations the Figure 4 is capable of producing 3D prints in a manner that may find industrial application.

Vote now for 3D Systems Figure 4 technology as the 3D Printing Industry Innovation of the year here.

HP Multi Jet Fusion

Multi Jet Fusion is HP’s foray into 3D printing and claims to be ten times faster than any other technology in the marketplace. The powder bed based method also uses an inkjet print head to precisely place a range of inks, before the layers are fused. The resulting 3D printed part density is comparable with injection molding.

As 3D Printing Industry heard during a recent visit to HP’s Corvallis site, the company believe that the Multi Jet Fusion 3D printer will be used intially for low volume production runs, but a longer term plan is to make the machine competitive with injection molded components at much higher volumes.

HP are working with 50 materials partners to expand the range of materials available on the platform, Evonik and BASF are early materials partners but with Materials Development Kit it is anticipated the options for printing will be widely expanded.

Jabil, Materialise and Shapeways are among the early adopters of HP’s Multi Jet Fusion, and as HP Labs CTO Shane Wall told us, the company has a remarkable vision for the future.

Vote now for HP Multi Jet Fusion as the 3D Printing Industry Innovation of the year.

Stratasys Infinite Build

Seen at IMTS 2016, the Infinite Build is Stratasys’s answer to large format 3D printing. By turning typical FDM 3D printing on its side, the system allows users to 3D print parts of indefinite length. It also incorporates a new screw extruder that, according to Dick Anderson, senior VP of Research and Development at Stratasys, “can print a part at 10x what we could do with our traditional extruder.”

The technology has gained the attention of industrial manufacturers such as Boeing and Ford. The automotive company are exploring the potential for the the Infinite Build.

Vote now for Stratasys Infinite Build as the 3D Printing Industry Innovation of the year.

WASP 3MT

The DeltaWASP 3MT is a 3 meter-tall multitool 3D printer. The interchangeable heads of the extruder allow the 3MT pelletized and liquid feedstocks, in addition to milling for the required finish.

The DeltaWASP was showcased at the MECSPE B2B manufacturing conference in Italy. WASP’s large format machines have also been used to create sculptures pushing the possibilities of design for additive manufacturing. Italy’s largest technical university, Politecnico di Milano, used WASP 3D printers to create the Trabeculae Pavilion on display at Milan’s MADE expo 2017.

Vote now for WASP 3MT as the 3D Printing Industry Innovation of the year.

Vote now in the 1st Annual 3D Printing Industry Awards

The 3D Printing Industry Awards is only two weeks away so make sure to vote now. If you think we’re missing anybody too, you can nominate a company for each category using the Wildcard option.

For the latest 3D printing news, subscribe to our newsletter and follow us on twitter and Facebook.

#3DPIAwards