By using a Stratasys Objet Eden350V 3D Printer, Queen Elizabeth Hospital in Birmingham, UK are saving three to four hours in surgical time per surgery, and costs are reduced by up to £20,000 per operation.

The hospital had previously outsourced its 3D printing requirements and have now installed an in-house 3D printer to facilitate life-changing maxillofacial surgeries. According to Stratasys 3D printing has, “revolutionised pre-surgical procedures across a number of departments. This includes the maxillofacial (face and jaw); burns and plastics; ear, nose and throat; and neurosurgery units.”

Substantial cost savings through 3D printing

Stefan Edmondson, Consultant Maxillofacial Prosthetist at the hospital said, “The ability to produce lifelike medical models in-house on our Stratasys 3D Printer saves around three to four hours in OR time per surgery, which at a cost of £5,000 an hour of operating room time, is quite a substantial cost saving.”

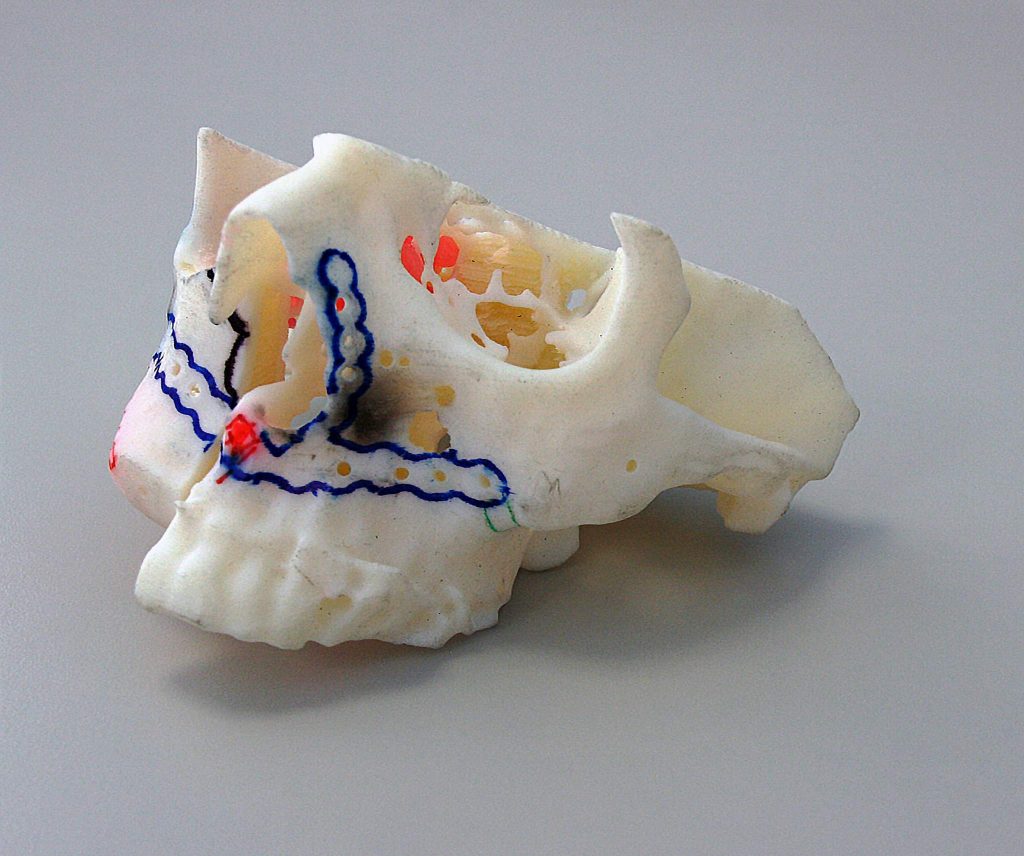

The maxillofacial prosthetic team converts patients’ CT scans into highly accurate 3D printed replica models, bone replacement parts or metal prosthetic plates that are customized to the exact specification of each patient.

“If we need to remove bone from a patient’s face, we can produce an exact 3D printed model to develop the cutting guides,” explained Edmondson. “This process results in more efficient clinical outcomes and saves the hospital, patient and medical practitioner valuable time and associated costs.”

As well as facilitating the production of surgical cutting guides to speed up extremely advanced procedures, Stratasys PolyJet 3D printing “allows surgeons to practice surgeries on true-to-life 3D printed anatomical models. This provides invaluable insight into procedural outcomes and helps minimize risks.”

Solutions for physicians

Scott Rader, General Manager, Healthcare Solutions, Stratasys said, “The advances Queen Elizabeth Hospital is making in the use of 3D printing in surgical planning are remarkable.”

Stratasys point to this use case as a clear demonstration of the ability for 3D printing to enable physicians to better plan, practice and determine the optimal surgical approach. In the current operating climate, physicians need solutions that can save time and money, while also improving quality of care. Queen Elizabeth’s implementation of 3D printing achieves these goals.

3D Printing Industry readers have nominated Stratasys for our 3D Printing Industry Awards. You can make your vote for the company here.

To be first with all the latest 3D printing news, subscribe to our free newsletter and follow our active social media accounts.

Featured image shows the hospital’s Stratasys Objet Eden350V 3D Printer and Consultant Maxillofacial Prosthetist Stefan Edmondson. Photo via Stratasys.