Researchers Benjamin Lehner, Dominik Schmieden, and Anne S. Meyer from the Delft University of Technology (TU Delft) in the Netherlands, have co-authored a paper exploring an inexpensive method of 3D printing bacteria.

The research demonstrates great potential for producing a range of smart, sustainable, and naturally biodegradable materials that don’t produce toxic waste.

An added challenge: keeping materials alive

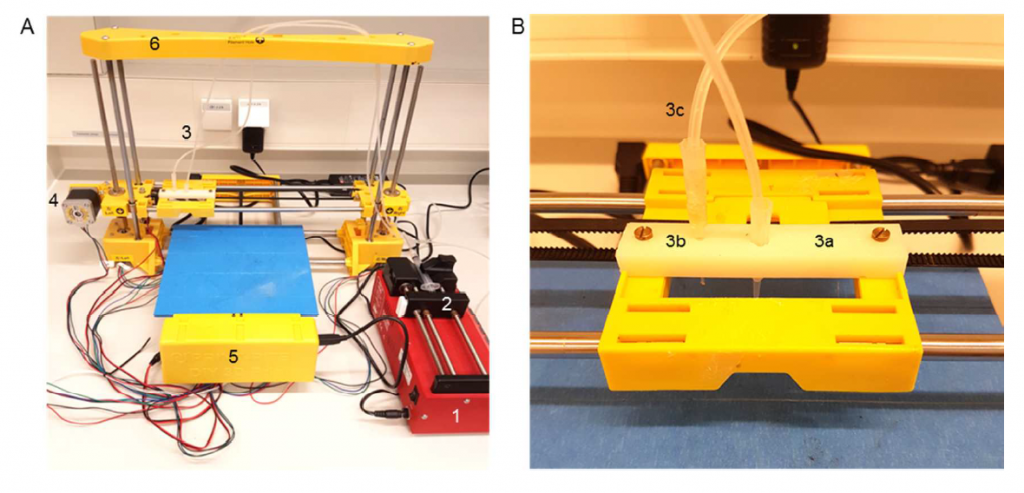

In their research, the TU Delft team from Department of Bionanoscience first produced a bioink by mixing E. coli strains into an alginate-based hydrogel. The challenge was then to 3D print this on a commercial 3D printer – the one chosen for this study is CoLiDo DIY 3D printer, retailing at around $300.

At the temperatures and stress of typical 3D printing, the E. coli ink would be destroyed. So, the researchers swapped out the extruder for a pipette to deposit the layers.

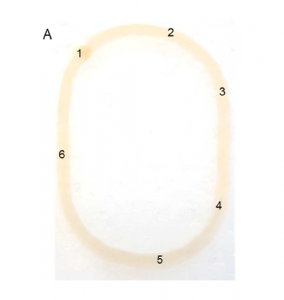

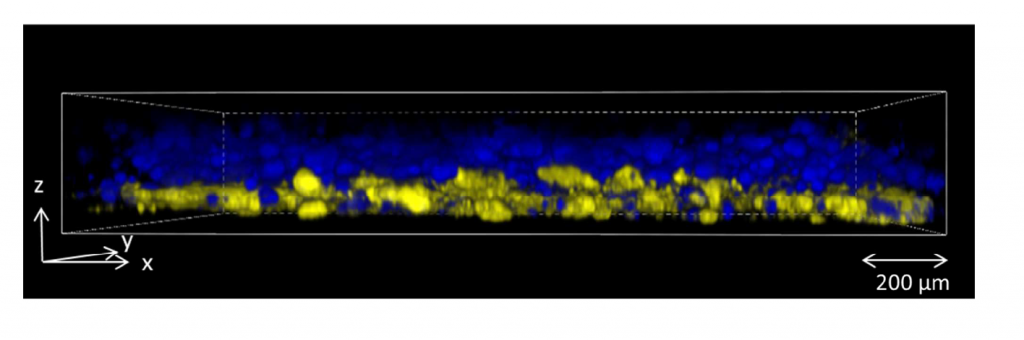

With this bacterial 3D printing system, the researchers then demonstrated consistent deposition of the bioink in the shape of a ring.

After 24 hours under constant light and incubation, the E. coli survived: confirming the efficacy of their system.

On the bacteria’s survival, the authors note,

Our printing technique is inexpensive, straight-forward, and can produce bacterial structures of a wide variety of three-dimensional shapes without requiring printing scaffolds, excepting structures that contain internal bridges or enclosed hollow spaces.

Our technology is well-suited for the use of wild-type organisms or synthetically modified bacteria, which could be designed to carry out new combinations of microbial reactions to create a great number of different types of materials.

E. coli – the key to future smart materials?

First discovered in 1885, E. coli is a pretty versatile and well-documented bacterium, making it ideal for experimental use. With a team of microbiologists at MIT, artist and researcher Neri Oxman used the bacteria to culture different colors in the Vespers series of 3D printed death masks.

E. coli is also used in synthetic biology at the US Army Research Laboratory (ARL) in Maryland, where researchers are harnessing bacteria’s powers to make microscopic devices to enhance the performance of soldiers.

Glowing bacteria is also being explored for its ability to reproduce the filters in LED screens, and has the potential to produce flexible devices.

A straightforward approach for 3D bacterial printing from TU Delft was published online at PubMed.gov on the 22nd February 2017.

To stay up to date with 3D printed biomaterial research, you can sign up to the 3D Printing Industry newsletter, and follow us on our social media channels.

Featured image shows the SEM picture of e coli from the National Institute of Allergy and Infectious Diseases (NIAID) on Flickr