If you ever get the chance to eat pumpkin dumplings – just do it! Ride the Shanghai metro, take a cab, compare the civility of the French Concession with the sterility of the Bund, and visit the people’s park to see parents selling their children’s future on the strength of an A4 marriage proposal pinned to an umbrella.

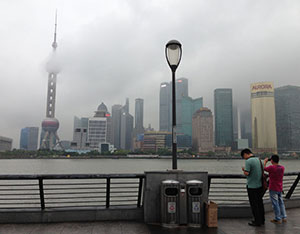

A 21st Century vista

Also, if you want to hypothesise about the future impact of China on the global 3D Printing economy, take an 11-hour flight and just come and talk with their industrial leaders, academics, government officials, journalists and party members – then take a big step back, a deep breath and a dose of sobering, yet refreshing reality.

Because what you soon come to realise is that the business drivers to 3D Printing adoption here in the East are very different to those in the West, and that it is these drivers for change that will shape the future global 3D Printing economy within the next 10-year cycle.

Ningboo: A city of ‘just’ 8-million people – not listed in my hotel phone guide, as it’s too small!

Within the West (by that I mean Europe and North America, as there is 3,000 miles of China to the west of me right now) we have spent years trying to justify the adoption of Additive Manufacturing (AM) into main stream production. Our drivers to adoption have been largely predicted on three factors – (1) product personalisation, (2) increased geometric freedoms and functionally and (3) low-volume / high value manufacturing.

In short, we want to use AM to enable the production of cost effective personalised products, that are manufactured closer to the point of consumption, with less raw material and a lower environmental impact. We want to use AM as an enabler to re-shore manufacturing from low-wage economies to our own indigenous economies, generating wealth, jobs and the diversification of largely 21stcentury service based economies.

However, here in China, the socio-economic drivers to 3D printing technology adoption are very different.

The most recent 5-year plan (the 12th so far), states that the country must become a knowledge driven economy, rich in product innovation, design, research & development – in consort with its mass production heritage. But to support this China does not need (or appear to want) Additive Manufacturing as we know it (for end-use part production)– rather it wants & needs 3D CAD, simulation and Rapid Prototyping technologies in numbers unfathomable in the west.

Moreover, it wants these technologies and material supply chains to be home grown, a concept soon to be supported through a network of ten 3D printing innovation centers funded with 2-Billion Yuan (RBM) of government investment.

BUT – exchange rates and sharing in the largest country on earth can make even very big numbers look quite small. In a country with 4 times more people than the USA and 20 times more than the UK, 2 Billion Yuan actually works out at £3-million per centre, with one 3D Printing centre per 135-million head of population. Compare that to the £100M invested in Additive Manufacturing within the UK since 2007, or the £150M invested by the EU over the same period. Consider the $100-million per annum cumulative combined R&D spend of 3D Systems, Stratasys, EOS & MakerBot and the realities of scale become apparent. This is not an investment in global AM supremacy, it is an investment in technology transfer leading to increased demand and local supply of Rapid Prototyping capability.

China will undoubtedly become (over time) a global supplier of form, fit and functional prototyping technology. I have no doubt about this. It will also become a source of capable materials and capable software tools needed within the product development process. But, within this 5-year plan and probably the next, it will not adopt or develop Additive Manufacturing technologies targeted at the end-use part production the west has identified.

Why – because there is simply no indigenous demand. Yet!

In summary, Chinas industrial policy should be seen as a wake-up call for western 3D printing technology vendors – “mature your RP technology towards production readiness and do it fast, as there is a competitive dragon coming with very big claws and a smoking nose. It might not be spiting fire just yet, but it will – and it will burn”

Reproduced with permission by Econolyst.