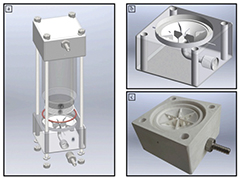

Until recently, researchers working in the field of soil science have had to resort to time consuming manufacturing processes for creating the necessary laboratory or field equipment for their research activities. With the aid of the latest 3D printing technology, researchers from the Soil & Water Engineering Laboratory are exploring new ways of working that free them from the restrictive technical constraints imposed by lathes and moulding processes and ultimately allowing more efficient information sharing and the ability to easily replicate findings from other studies within the scientific community.

Even after research was completed and published, anyone interested in replicating the scientific work had to try and duplicate the equipment used in the process. This caused a further strain both for the person conducting the research and documenting the schematics of the equipment as well as for the entity wanting to replicate the process.

Using modern 3D printers and relevant design software, these constraints no longer apply. The researchers can now disseminate precise information about the equipment they need to use and easily share it via email or other digital communication methods.

The Soil Science Society of America Journal wrote in their June 2012 issue, that 3D printing is now at the stage where it can be used effectively to produce sophisticated apparatus for use in soil science research. The digitation of the design and manufacturing processes enable fast modification and reproduction times. The journal also suggests that the use of CAD design and 3D printers, the curriculum for students studying this field can be enhanced to include instrument design amongst other approaches, making the courses more attractive to the wider student body.

Faster turnaround times are certainly attractive to any field of science – or business for that matter. Time savings coupled with reduced costs of manufacture is promising for 3D printing and scientific work going forward. The journal concludes: “Therefore, it seems reasonable to expect that this technology will revolutionize the way we design and replicate experiments in soil science, as in most other disciplines.”