3D printing, as it applies to the field of medical science, has proven very useful. 3D printed prosthetics have helped patients regain mobility and confidence, while breaking the price point down to the realm of affordability. 3D printed models of patient-specific hearts, skull, and livers have helped doctors plan safer and less invasive surgeries. 3D printed implants, such as vertebrae and skull bones, have helped doctors restore functionality while relieving chronic pain and disfiguring scars. There’s so much promise for these types of applications, and the importance of having accurate models for visualization should not be underestimated or taken for granted.

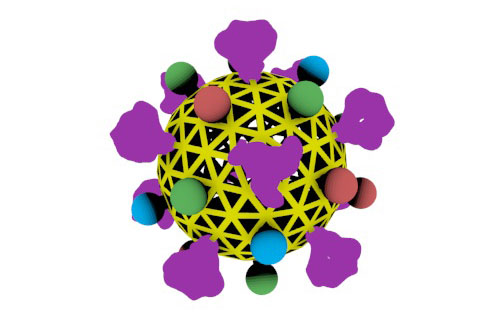

Arthur Olson is a molecular biologist at the Molecular Graphics Laboratory at the Scripps Research Institute in La Jolla, California. He’s using 3D-printed models to understand how HIV functions and sharing his models with other researchers through the National Institutes of Health’s 3D Print Exchange. Covered by our Editor, Michael Molitch-Hou, back in May, this phenomenal website gives scientists a place to post instructions for 3D printing models of molecules, axons, organs, bones and other biological entities.

According to Arthur, having added a kinesthetic element to visualization greatly helps medical explanation and discovery. “The experience itself is very different between looking at something on a flat screen, and actually holding an object and manipulating an object in your hands.” Anything that helps researchers figure out new ways to interrupt the processes of HIV virus molecules would be welcome knowledge to assist in the fight against the deadly epidemic.

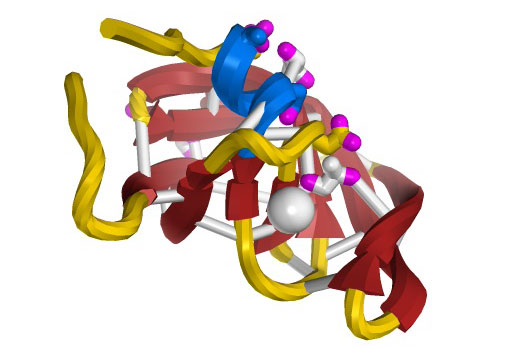

How do proteins fold up? They contain thousands of atoms and interactions between individual molecules. So how does holding a 3D printed molecule differ from a 2D simulation?

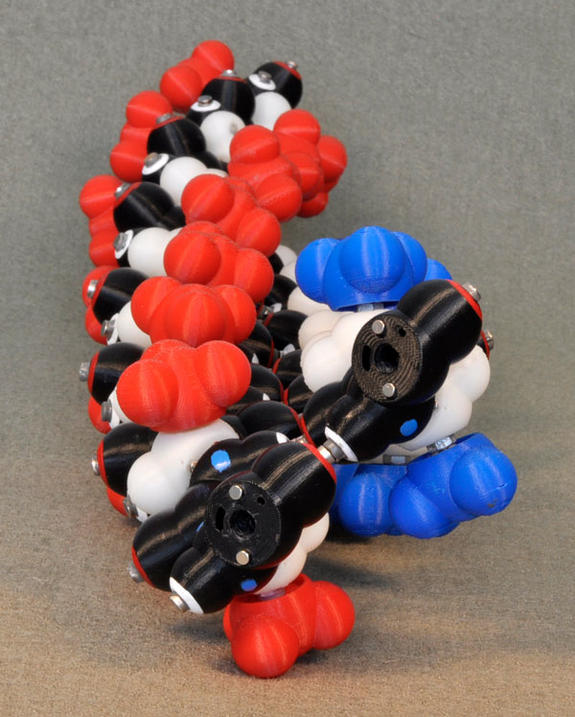

Sometimes in a 2D visualization, digitally moving the molecules to simulate interactions between molecules can yield unrealistic results, like a molecule physically passing right through another molecule. It becomes obvious with a 3D printed model that two solid molecules have more realistic and physically accurate limitations.

Where do the insights come from by having the 3D printed molecules in your hands? Inside of many proteins exist long curving tunnels. Molecules pass through these tunnels. The problem on a computer is that it is hard to measure the length and width of these tunnels and see all the way through them. According to Olson, measuring its length is much easier in 3D-printed models. He said, “All you have to do is take string, push it through the tunnel, mark the ends, stretch it out, and you know how long the tunnel is.”

Another characteristic of proteins is that they can be used as sensors for small concentrations of molecules, but are often too fragile to exist in certain weather conditions. Police or military could use proteins to detect a biological attack in a subway or airport according to Ron Zuckerman, who is a nanobioscientist at the Molecular Foundry at Berkeley Lab in California.

Zuckerman’s team began to use 3D printing to gain a more intuitive approach to creating artificial proteins. By holding the 3D printing proteins, Ron and his researchers understand the range of flexibility proteins exhibit, which makes it easier to understand how they fold. By using tiny magnets on the models, the forces between molecules can be modeled. And, with different materials, the models can mimic the flexible characteristics of different proteins. Zuckerman is developing synthetic peptoids, which are molecules that would have the same sensitivity of proteins that makes them fragile, but could instead be made of stronger and more durable synthetic amino acids.

For educational purposes, Zuckerman is now using 3D printed models of real proteins he calls “peppytides”, to demonstrate how common structures of proteins emerge.When students start with a 3D model, “I can give you this floppy thing like a necklace that’s just wiggling around and you can actually fold it,” Zuckerman said. “All of a sudden the helical folds start to become stable because all the magnets line up.”

As we move into 2015, which I think will be the year of new materials and acquisitions, we can look forward to new medical applications that will continue to set high benchmarks for the utility of 3D printing, as we eagerly await a rare leapfrog innovation with great anticipation and awe.