Malaria is an infectious disease caused by microscopic parasites (called Plasmodium) transmitted through the bite of a female mosquito. According to UNICEF, a child dies of malaria every two minutes.

To combat the spread of malaria and support the development of vaccines, scientists use Standard Membrane-Feeding Assay (SMFA) tests which measure the ability of antibodies to block transmission of parasites to mosquitoes.

Membrane feeding apparatuses commonly use electric heating elements or complex glass chambers to warm blood infected with parasites which simulates body temperature and skin of the host. However, both of these methods are expensive to purchase and can only be sourced from specialized companies.

Thus, researchers from Imperial College London (ICL) have created an inexpensive open-source 3D printable membrane feeder to better equip a wider range of laboratories with customizable SMFA tools for scientific malaria experimentation.

Experimentation with a 3D printed membrane-feeding apparatus

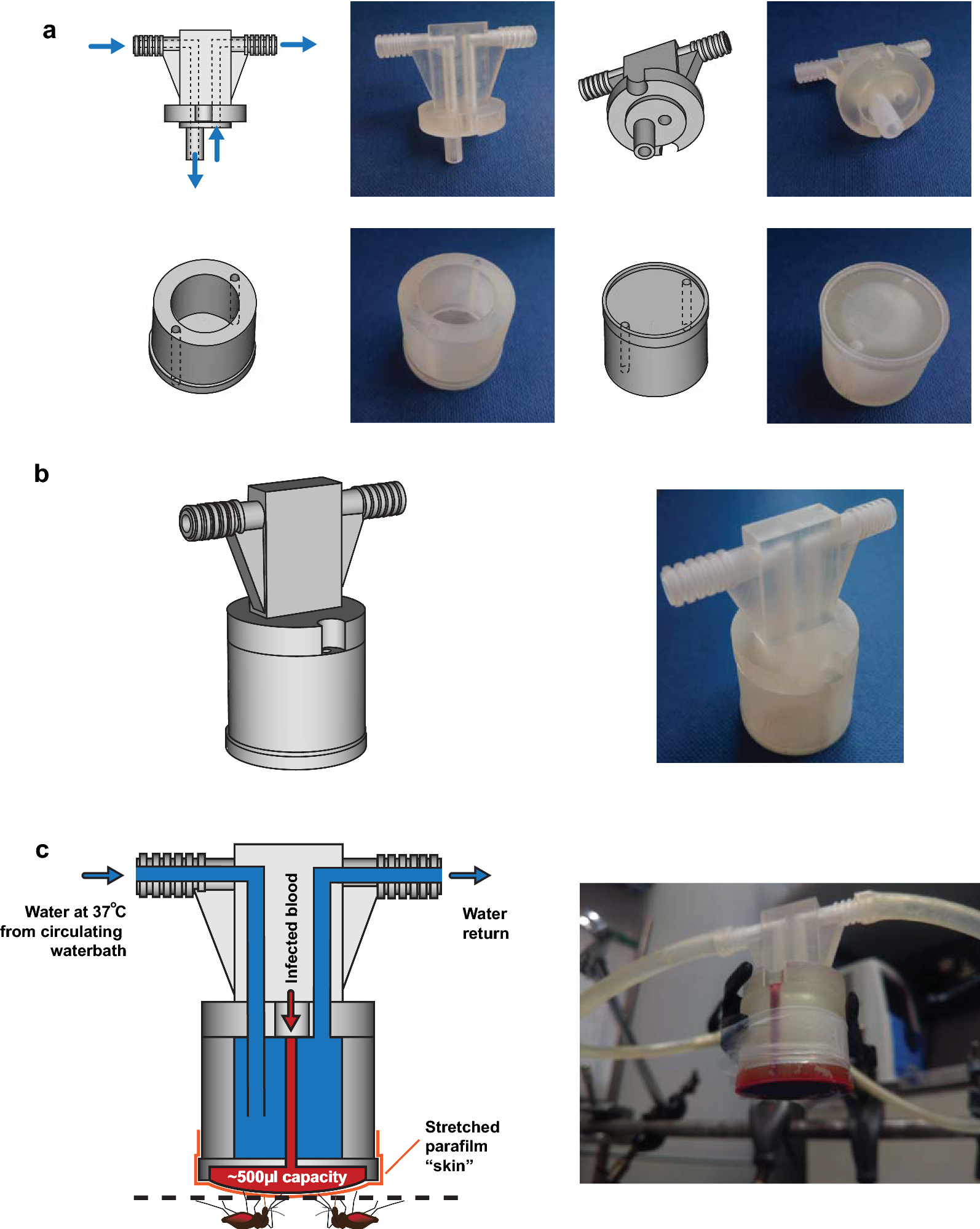

Using the open source CAD modeling program Art of Illusion, ICL researchers created a two-part membrane feeder design and sought out Shapeways, who fabricated the parts using stereolithography 3D printing. The membrane-feeder is made from USP VI medical-grade “Fine Detail Plastic” acrylic resin.

The researchers decided to conduct three independent SMFAs, using a traditional Plasmodium falciparum NF54 laboratory glass strain to compare the performance of their 3D printed membrane feeder.

According to the study, “transmission of malaria from vertebrate host to mosquito is mediated by the mature sexual stages of the Plasmodium life cycle—male and female gametocytes.” With this basis, the researchers began feeding mosquito test-subjects with gametocyte-infected blood in both the 3D printed and traditional membrane feeding systems to study cell biology, vaccine, and anti-malarial drug development.

“Membrane feeding requires a gametocyte-containing blood meal, a source of heat to maintain the blood at 37 °C (to ensure gametocytes are not prematurely activated and to simulate body temperature to promote mosquito feeding) and a membrane around the blood to simulate the skin of the host.”

Commonly SFMA tests use Hemotek, a feeding system in which infected blood is placed between electrically heated feeder reservoirs and a surrounding membrane. In addition, a water-jacketed glass or plastic feeder can be used, which involves heated water from a circulating water bath that passes through a feeder to warm the infected blood sample.

The study found “no statistically significant difference[s]” in the performance of the water-jacket 3D printed apparatus against the traditional Plasmodium falciparum NF54 laboratory glass strain.

“Exflagellation rates (the formation of malaria parasites by extrusion of nuclear material into peripheral processes resembling flagella) as well as oocyst counts (a cyst formed by malaria parasites) indicate that there is no significant difference between the two, within the statistical power given by triplicate SMFA’s used as standard by the research community.”

Additive manufacturing and labware

3D printing technology has previously been used to create laboratory equipment utilized in combatting life-threatening diseases such as malaria.

In 2016, Chris Lim, University of California Irvine (UCI) student, proposed a cost-effective method using additive manufacturing to create microfluidic devices which correctly identify diseases such as malaria.

Prior to this, Professor Lee Cronin, Regius Chair of Chemistry at the University of Glasgow, UK, made his case on how 3D printing combined with robotics and chemistry can revolutionize laboratory environments and improve the development of antimalarial pharmaceuticals in developing countries.

The research paper titled An inexpensive open-source 3D-printed membrane feeder for human malaria transmission studies is co-authored by Kathrin Witmer, Ellie Sherrard-Smith, Ursula Straschil, Mark Tunnicliff, Jake Baum, and Michael Delves.

Stay abreast of the latest news in 3D printing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the top component of the 3D printed membrane feeder. Image via ICL.