Georgia Institute of Technology researchers, together with the Piedmont Heart Institute, have created a patient-specific heart valve model using a 3D printer.

In a bid to improve the success rates of transcatheter aortic valve replacements (TAVR), the researchers say creating patient models will allow doctors to better prepare for heart surgery. With the models they hope to improve the fit of heart valve prosthetics and avoid paravalvular leakage.

To take the models one step further, the researchers also now envisage using 3D printed electronics to create embedded sensors for data collection. Previously Georgia Tech researchers have employed 3D printing to create shape-changing tensile shapes.

Gif shows simulation of heart valve function. Images via Georgia Tech.

Preparing valve replacement

Zhen Qian, chief of Cardiovascular Imaging Research at Piedmont Heart Institute, worked on the project with the Georgia Tech researchers and he explains,

In preparing to conduct a valve replacement, interventional cardiologists already weigh a variety of clinical risk predictors, but our 3-D printed model gives us a quantitative method to evaluate how well a prosthetic valve fits the patient,

Using the 3D printed valve, which was created using patient’s CT scans, the researchers were able to study the expected flow of blood with a warm water testing environment. This testing revealed the fit of the valves and whether there was any leaking.

Paravalvular leakage

Zhen Qian explains one of the most important factors in valve replacement treatment is paravalvular leakage which is where blood flows around rather than through the prosthetic valve. Qian states “paravalvular leakage is an extremely important indicator in how well the patient will do long term with their new valve.” Addressing this, Qian says,

… now that we can make a patient-specific model with this tissue-mimicking 3-D printing technology, we can test how the prosthetic valves interact with the 3-D printed models to learn whether we can predict leakage.

Multi-material 3D printing

The valve models are created “with a special metamaterial design” and 3D printed on a multi-material 3D printer. The team inserted stiffer materials into the soft flexible polymer which allows the valve to naturally stretch with bloodflow but also maintain its strength.

Working alongside Zhen Qian was Chuck Zhang, a professor in the Stewart School of Industrial and Systems Engineering at Georgia Tech, and he documents the importance of using more than one material,

Our method of creating these models using metamaterial design and multi-material 3-D printing takes into account the mechanical behavior of the heart valves, mimicking the natural strain-stiffening behavior of soft tissues that comes from the interaction between elastin and collagen, two proteins found in heart valves.

Printed electronic valves?

In a video uploaded by Georgia Tech, research engineer Kan Wang reveals the research team now intends to use “aerosol jet printing” to print electronic sensors into the valve to collect even more data.

Wang may have been referring to Albuquerque’s Optomec, the creators of Aerosol Jet Technology and developers of printed electronics including turbine blade sensors for GE.

The current research has been published in the JACC: Cardiovascular Imaging journal, titled ‘Quantitative Prediction of Paravalvular Leak in Transcatheter Aortic Valve Replacement Based on Tissue-Mimicking 3D Printing.’

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

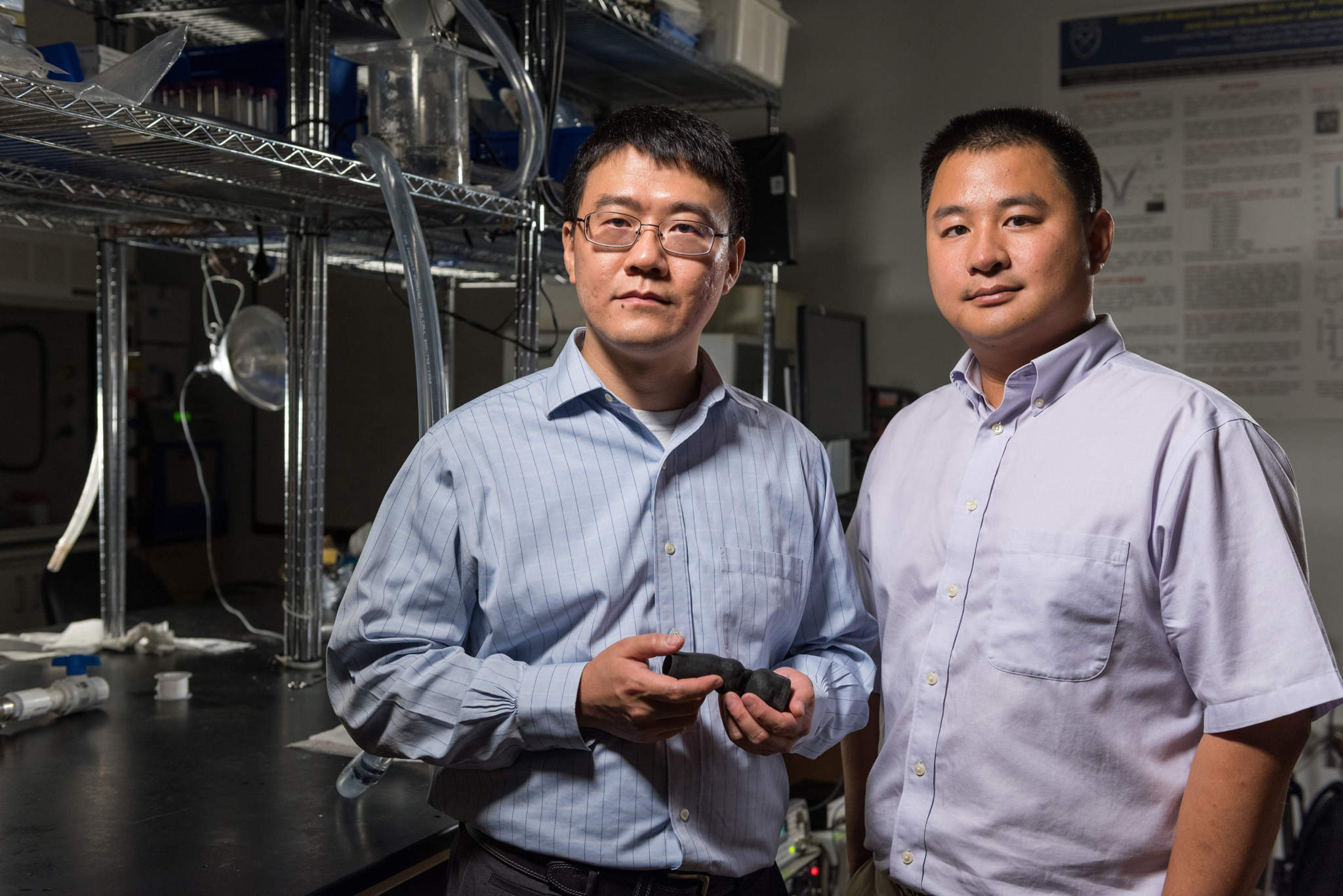

Featured image shows the 3D printed heart valve. Photo via Georgia Tech.