Researchers at the Chinese Academy of Sciences have 3D printed a novel nanogenerator with the potential to enable the self-powered monitoring of autonomous vehicles.

Referred to by its creators as a ‘BS-TENG,’ the tiny 70mm triboelectric nanogenerator (TENG) features a unique bearing structural (BS) design, that allows it to serve as both a mechanical energy harvester and a self-sufficient sensing device.

Capable of operating at up to 1,500 rpm, each ultra-compact BS-TENG can deliver a peak output of 0.96 mW, which according to the team, is sufficient to either power 50 LEDs, or enable the thermal and speed monitoring of AI-driven vehicles, in a way that “provides new opportunities for intelligent automobile driving systems.”

Eco-friendly autonomous vehicles

As the convergence between AI and commercial vehicles continues to pick up pace, the issue of powering them sustainably has grown in tandem. This is because the integration of such advanced processing systems may hold the potential to make autonomous cars safer and more reliable, but they often also rely on the use of non-renewable batteries and power nodes.

Many existing systems use cells that require regular time-consuming charging as well, which need to be integrated into complex networks, effectively increasing their overall cost of development and production for automotive manufacturers.

As an alternative to conventional batteries, it is possible to harness and deploy the rotational mechanical energy generated via vehicle turning and braking, to power internal automotive monitoring systems. In fact, the first nanogenerator was created 15 years ago by a team at the Georgia Institute of Technology, which has since gone on to develop a TENG capable of capturing wind and kinetic energy.

However, the Chinese researchers now claim that the limited energy conversion of existing technologies, in addition to the demands of AI vehicles, is preventing their wider adoption. To get around this, the scientists say they’ve devised a new harvesting approach, which enables the use of previously-wasted energy to power a sensing system that allows for “the safer driving of automated vehicles.”

Energy harnessing with the ‘BS-TENG’

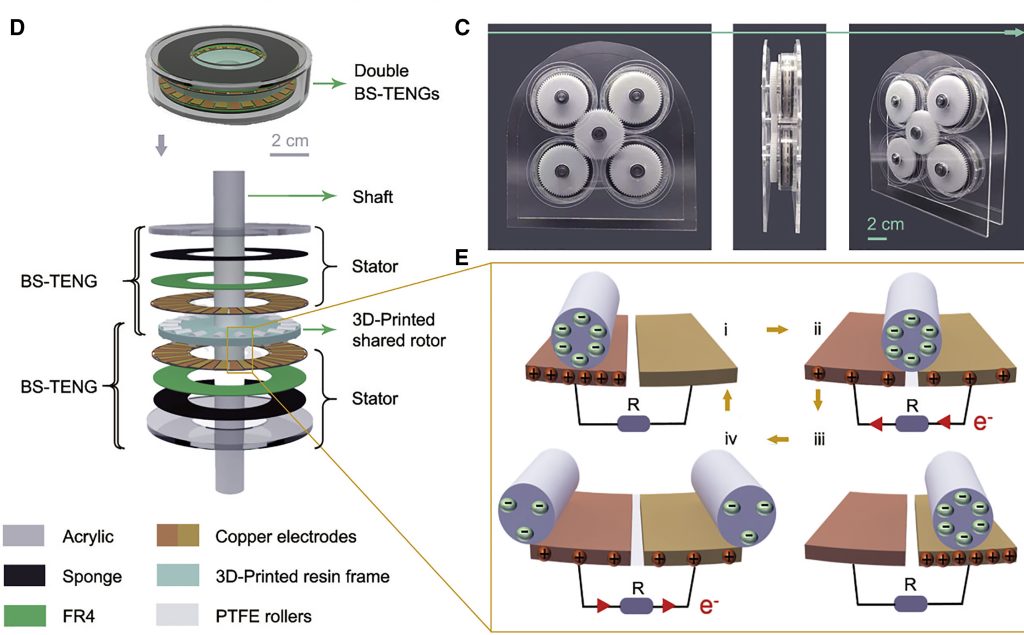

In order to overcome the drawbacks of existing TENGs, the Chinese scientists went back to the drawing board, adopting 3D printing to create an entirely new design. What they came up with is a nanogenerator composed of a rotor and stator adhered to acrylic plates, with the former featuring a printed frame, in which PTFE rollers alternately rotate to connect electrodes and generate electrostatic charges.

Due to its experimental nature, the prototype rotor only had a height of 3.6mm, so to make room for the device’s 6mm rollers, the researchers fused two rotors with an acrylic tube to form a ‘double-BS-TENG.’ During testing, the resulting nanogenerator proved capable of a high and stable output at 100 to 1,500 rpm, thus the team theorized it could be used for “mechanical energy harvesting by wheel rotation.”

To put this hypothesis into practise, the scientists then integrated their device into a self-powered vehicle monitoring or ‘SPVM’ system, comprising four double-BS-TENGs, five gears and two acrylic plates. Initial tests showed the nanogenerators were able to power a thermal sensor, that could not only be operated continuously, but programmed to sound an ‘alarm’ when a certain temperature was reached.

Further assessments also showed that the SPVM can be used to track servometer-simulated wheel speed simultaneously, showcasing its multifunctional end-use capabilities. With further R&D, the team therefore believe the BS-TENG has the potential to be a “breakthrough in rotational energy harvesting,” that provides a blueprint for improving both the efficiency of nanogenerators, and safety of AI-driven vehicles.

“Integrated BS-TENG networks can be utilized as both a rotational energy harvester and a self-powered high-speed sensing system for vehicle temperature and real-time speed monitoring,” concluded the team in their paper. “Furthermore, the results confirmed that the accuracy of self-powered vehicle speed monitoring could reach more than 99%, indicating that their design is reliable for practical applications.”

3D printing’s EV applications

As impressive as the Chinese scientists’ BS-TENG is, it’s far from the first time 3D printing has been used to create energy-generating or storage devices, and the technology is now increasingly attracting the attention of the automotive industry.

Just last year, UK-based 3D printer manufacturer Photocentric established a dedicated battery 3D printing division, with which it has committed to developing more eco-friendly and efficient cells. Although the firm has yet to reveal how these revised batteries will work, or its plans for bringing them to market, it’s thought that they’re specifically being designed to address the electronic vehicle (EV) sector.

The Sakuu Corporation has also dedicated itself to the development of optimized Solid State Batteries (SSBs) for automotive purposes, and it unveiled its new Sakuu AM Platform in May 2021. With its upgraded 3D printer, the firm aims to reduce the cost, scale and consistency roadblocks to introducing such SSBs to market, and ultimately drive the wider adoption of sustainably-powered transport.

Elsewhere, in 3D printing tests similar to those carried out on the BS-TENG, a team at the Ulsan National Institute of Science and Technology have devised a 3D printable ink for producing unique power-generating tubes. In practise, the researchers believe such tubing could form the basis of new thermoelectric generators, capable of capturing and reusing automotive exhaust gases.

The researchers’ findings are detailed in their paper titled “3D-printed bearing structural triboelectric nanogenerator for intelligent vehicle monitoring,” which was co-authored by Jin Yang, Yanshuo Sun, Jianjun Zhang, Baodong Chen and Zhong Lin Wang.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a mock-up of an autonomous vehicle with a part-3D printed self-powered sensor system. Image via the Cell Reports Physical Science journal.