The chair represents the height of design. This iconic piece of furniture is so simple that the process of performing any modification to it is a tightrope walk between pointlessly ornate and unneeded understatement. The test of any true designer, then, is what s/he can do to somehow improve upon this elegantly straightforward structure. German furniture firm Bernotat & Co. has passed this test, creating a chair that reflects the timeless nature of its design with the 3D-printed Cellular Loop Chair.

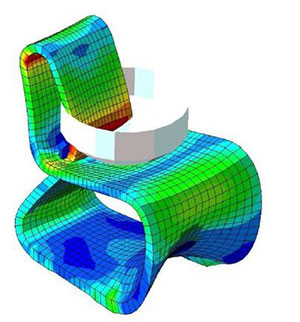

The organically sleek infinity sign that is the Cellular Loop Chair is the product of designer Anke Bernotat, of Folkwang University of the Arts, in conjunction with Franhofer UMISCHT¹ and members of the German Federal Ministry of Education and Research. 3D printed using selective laser sintering as one single, self-penetrating network of individual squares of plastic, the cantilever² chair was an attempt at making a chair that was both comfortable and supportive, while also made from the least amount of material possible. To achieve this, they sought inspiration from some truly amazing structures found in nature.

The chair is made up of a network of trabeculae, the tiny rods that comprise the interior of bones. Because bones are meant to be lightweight, but strong enough to support the weight of an organism, they provided the perfect model for the chair’s structure:

- Trabeculae are arranged at random and always create a diagonal connection between two points of the inner bone shell. The architecture of the tissue depends on whether the respective bone section is mainly exposed to pressure, torsion or bending forces. For designers, parametrically adaptable trabecula structures offer the possibility to detach the mechanical characteristics (e.g. stiffness) from the exterior shape of an object.

Another impressive piece of biology that inspired the chair’s structure was the healing process of trees. When a branch dies, the wood grows and forms around the wound, leaving a knot. As the designers put it, “The healing process reduces the notch stress and re-establishes the homogenous distribution of stress. This adaptive growth as a response to high strain served as a model for the transition from narrow to wide to narrow trabecula structures at the intersection of backrest and seat of the Cellular Loop chair.”

The Cellular Loop Chair really is an amazing piece of design and was selected as OVER-WINNAARS by the Zetel Foundation, as a part of the exhibitions at OBJECT Rotterdam. But, if you’re interested in other, non-3d-printed works by Bernotat & Co, you might be interested in their Chair Wear, chairs draped in various fabrics that allow you to stick your hands in their pockets or put your head in their hoods.

Source: Bernotat&Co.