Polish FFF 3D printer producer and service provider Omni3D has launched a CO₂ reducing R&D project with Cyprus University of Technology. The goal of the project is to make a reactor capable of turning carbon dioxide into biomethane and/or ethanol, which can then be used as alternative fuels.

Using OMNI3D’s expertise, the reactor will be made using 3D printing.

“We believe that including Omni3D in this kind of project gives an opportunity to show new 3D printing implementations of our technology,” says Omni3D CEO Paweł Robak. “It is also an attempt at recognizing responsibility and making entrepreneurs aware of the growing risk of […] global warming.”

“The success of the project is dependent not only on the work of the consortium members, but also on an active participation of countries demonstrating significant CO₂ emission.”

Turning carbon dioxide into fuel

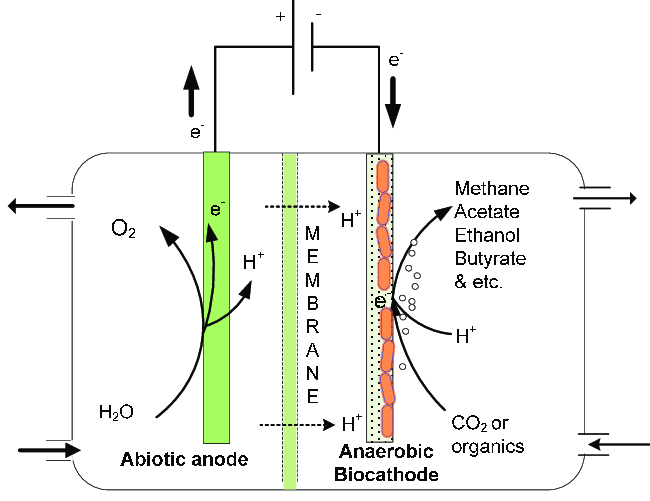

Within this project, Omni3D and collaborators are focusing on the development of a Microbial Electrosynthesis Baffle Reactor. This reactor is used to convert carbon dioxide to fuel in a process known as microbial electrosynthesis (MES).

Inside the reactor are living microrganisms. When an electric current is applied via a cathode, the microgranisms use the electrons to reduce carbon dioxide content. Methane, acetate and ethanol are all examples of renewable fuel sources produced via this method.

In the first step of the project, the Omni3D team seeks to develop thermoplastics suitable for production of the reactor. The second step will then be building a prototype 3D printer suitable of mass-producing the reactors

Krzysztof Kardach, chief technologist at OMNI3D, comments, “The final product of the project will help to fight with power shortage and, most importantly, it is a great advantage for industries emitting CO₂ and common citizens as well.”

“There will be two advantages: less CO2 in the atmosphere, and the biogas, that can be [stored] and used in households and vehicles as a power source.”

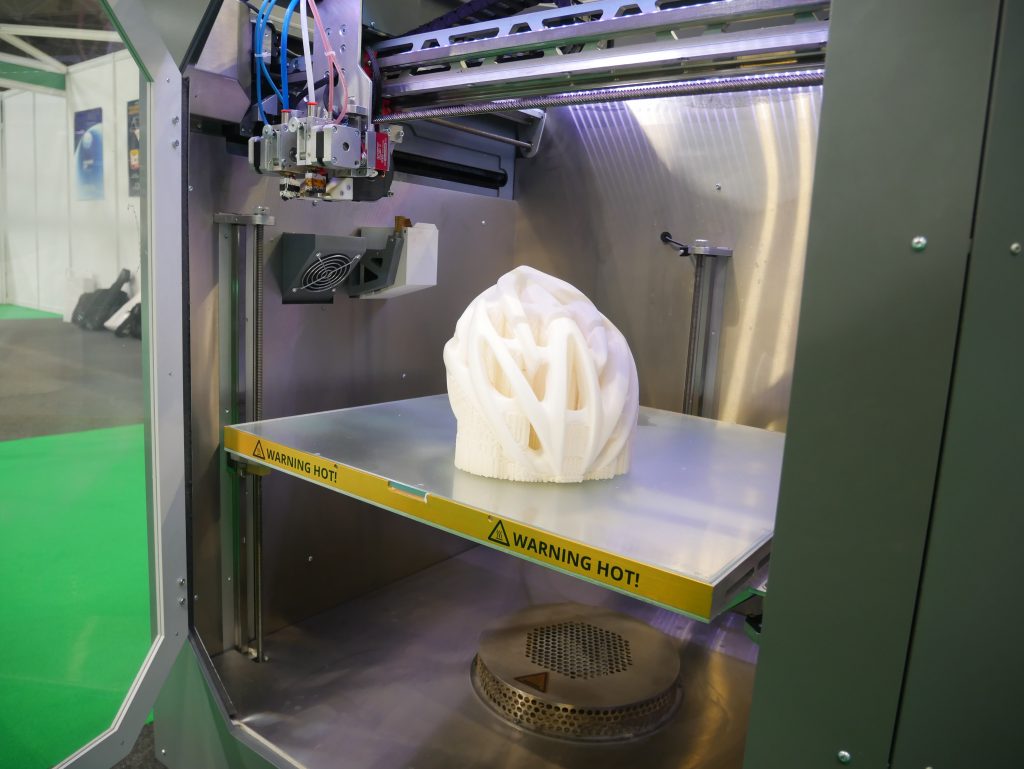

The Omni3D Factory 2.0

Omni3D’s 3D printers are industrial scale machines. The Factory 2.0 is the company’s latest system, offering dual extrusion and a build area measuring 500 x 500 x 500 mm. In 2017, the Factory 2.0 was applied to the production of parts for the Arrinera Hussarya – Poland’s first supercar. The system is capable of processing high strength thermoplastics, such as ABS, HIPS PET-G and nylon.

In addition to Omni3D and the Cyprus University of Technology, the 3D printed bioreactor R&D project has the support of two other entities:

– Research and Innovation Centre Pro-Akademia, part of Poland’s Ministry of Science and Higher Education and,

– Cypriot energy consultancy Eneres CPM Ltd

Are Omni3D and Cyprus University of Technology your Research Team of the Year? Nominate them and more now in the 2019 3D Printing Industry Awards. For more 3D printing news updates subscribe to our newsletter, follow us on Twitter and like us on Facebook. Visit 3D Printing Jobs for new opportunities in your area.

Featured image shows the Omni3D team and their Factory 2.0 3D printers. Photo via omni3d.com