Large-scale 3D printer manufacturer 3D Platform, headquartered in Illinois, has demonstrated great potential to save on tooling costs against traditional machining.

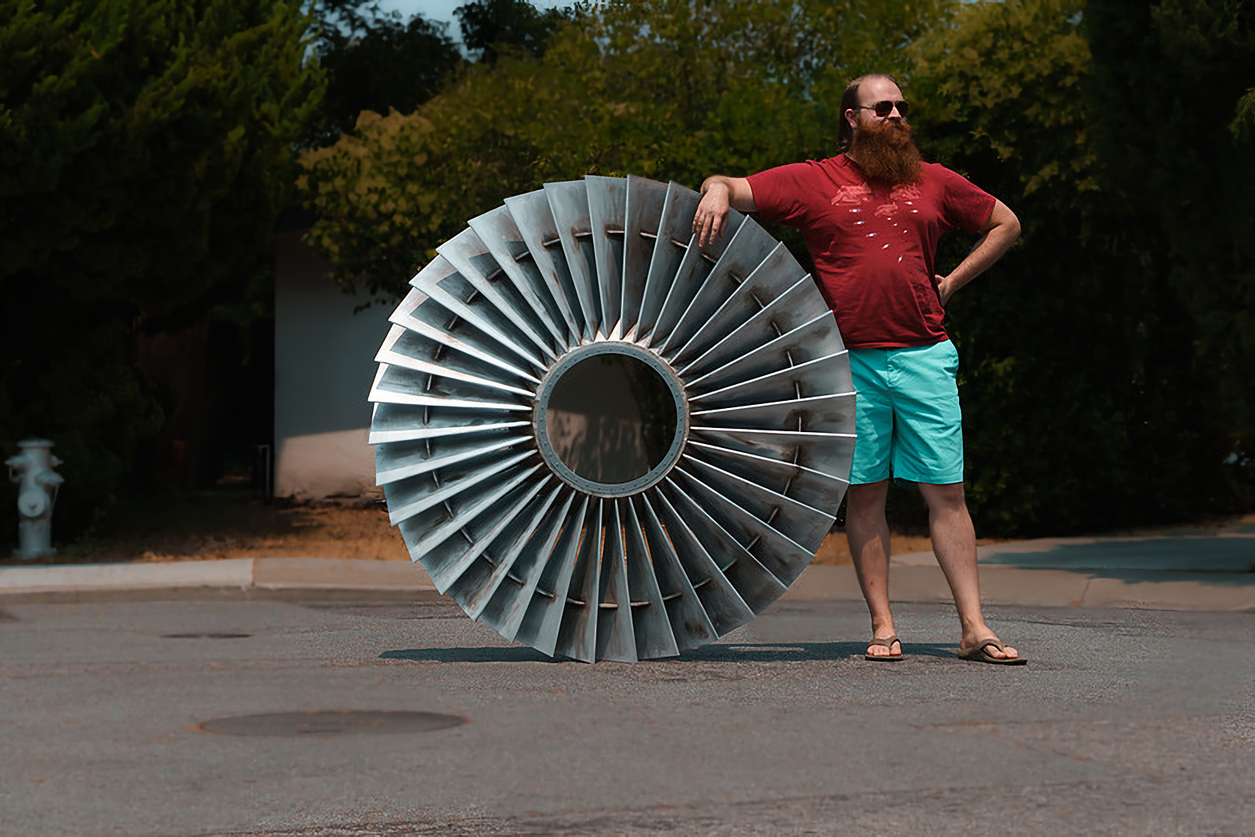

In a further case study, with San Francisco service bureau Titanic Design, the company’s hardware has also been put to the test, creating a life-size replica turbofan of a Boeing 737.

Machining v 3D printing

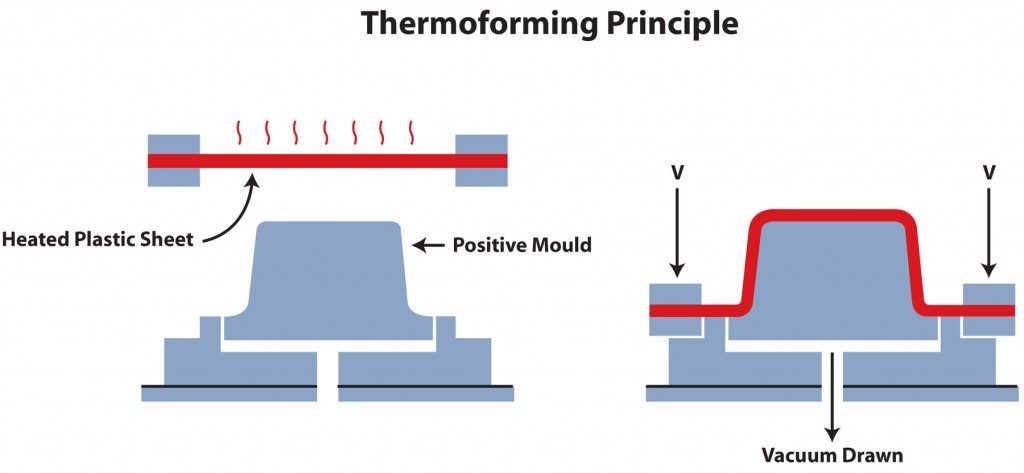

Thermoforming is a process where a plastic sheet is heated up until it hits a malleable temperature. Once its reached this temperature, the sheet is placed over a single-sided master mold and given shape. The plastic is then held in place as it cools down and hardens, after which any excess material is trimmed off the final product.

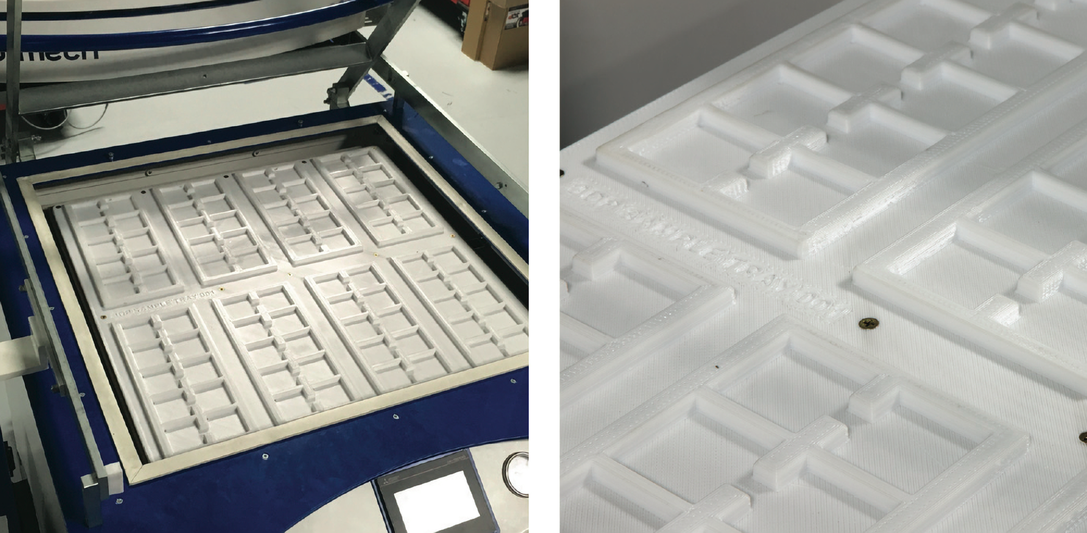

Traditionally, CNC machining would be used to make the master molds. At 3D Platform, large scale 3D printing was used in place of machining to make 8 customized master templates for comparison.

The 8 trays were 3D printed on a single 2ft by 2ft sheet, using Polymaker PC-MAX – a polycarbonate engineered to print at slightly lower temperatures than other polycarbonates.

In the case study, it was reported that the cost for 3D Platform printer materials was $53 per kilogram, with total material cost of $106. Additionally, the cost to run the machine was $50 per hour. The 3D printer required 24 hours to print the master molds, resulting in a total operating cost of $1200. Combining the operating costs and the $500 post-processing cost brings the overall price of the master molds to $1700, or $212.50 per mold.

By comparison, CNC machining the same parts would have taken 20 hours but, with higher operation and post processing costs, it would set a manufacturer back $2,500.

3D printed efficiency and affordability

In a second case study Tom Price, the owner of Titanic Design, investigated 3D Platform’s hardware as a cost-effective method for bespoke prototyping services.

Price stated “If you want the closest thing humanity has to a matter materializer that will let your engineers not have to think, then go get a $500K machine, add the infrastructure, service, proprietary materials, inflexible process required to it, and you will hemorrhage money. In the end it will be so much that it will be cost prohibitive.”

For Titanic Design, at $36,999, 3D Platform WorkSeries printers proved to be the smartest investment, with hardware and materials costing 1/10th of the closest comparable system. Additionally, 3D Platform printers had a much larger array of usable material than its closest comparable printer.

In the most recent use case from Titanic Design, the team 3D printed a 1:1 scale replica of the Boeing 737’s main bypass turbofan measuring at 1.55 meters in diameter.

“We run our machine hard and it shows almost no signs of wear. This machine directly competes with the best equipment on the market,” said Price “The cost and speed of the machine lets us directly challenge the status quo and best practices in hardware product development, and even challenge what qualifies as a final product.”

Titanic Design is now planning to add a second printer to keep up with 3D printing demand.

The change to 3D printing

Several other companies are reducing the cost of tooling by making the switch to 3D printing, such as the Volkswagen Autoeuropa factory in Portugal. The factory began using 3D printers back in 2014, saving the company an annual $160,000 and reducing time spent on tool development by 95%.

The Moog Aircraft Group, which specializes in aerospace technology, recently conducted a case study which concluded that 3D printing was 10 times cheaper than traditional tooling.

Last year, Aernnova, a spanish airbus manufacturer, changed to 3D printing which proved to be cheaper, lighter and more time efficient than the conventional tooling method.

In our ‘The Future of 3D Printing’ series, Jonathan Schroeder, President of 3D Platform stated “Over the next five years, we are going to see more printing being done for production and manufacturing. It’s going to start (and has already started) within the industries that can afford material premiums over traditional manufacturing because of the weight, efficiency, and design savings. We’ll then start to see manufacturing use 3D printing for production—primarily for low-volume prototyping or replacement parts for retired products.”

For all the latest materials, software and hardware releases subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter. Seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Feature image is the replica of the main bypass. Photo via Titanic Design