Trinity College Dublin (TCD), in Ireland, is to be the recipient of a new specialist 3D bioprinting facility supported by a collaboration between multinational medical device and pharmaceutical company Johnson & Johnson, and the AMBER research center.

With preparations beginning in the first quarter of this year, the new 3D bioprinting laboratory is due to be opened by the close of 2018.

Professor Michael Morris, AMBER director, comments,

“This lab is the result of a shared vision to create a global center of excellence for 3D bioprinting within the center,”

“This has been made possible because of the calibre of our world leading academics, state of the art equipment and supporting facilities and infrastructure.”

An intentional center of excellence

Established in 2013, AMBER stands for “Advanced Materials + BioEngineering Research”. The center is funded by Science Foundation Ireland and co-located at TCD, University College Cork and the Royal College of Surgeons in Ireland.

From 2013 – 2017, the AMBER center has seen Ireland rise through the ranks of international excellence in nanoscience and materials science research, where it was most recently ranked within the top three.

Professor Mark Ferguson, director general of Science Foundation Ireland and chief scientific adviser to the government, comments, “I very much welcome this promising collaboration between AMBER and Johnson & Johnson Services,”

“[It] builds on Ireland’s international reputation for research excellence and presents us with an important opportunity to promote the sharing of knowledge and expertise between industry and academia – in material sciences and beyond.”

Medical partnerships

The center has a long standing partnership with Johnson & Johnson’s DePuy Synthes orthopaedic franchise, that recently acquired custom implant 3D printing technology from Michigan-based Tissue Regeneration Systems.

To start, AMBER will initially engage in orthopaedic research projects, and offer in house experts as adjunct professors. According to Morris, the intention is to continue expanding the breadth of the company’s partnerships across “ICT and manufacturing sectors.”

In recent years, Johnson & Johnson has signed 3D printing partnerships with Carbon, HP and Carbon and Aspect Biosystems. With Aspect in particular, Johnson & Johnson is developing a method to 3D print replacement knee tissues.

Toward personalized healthcare

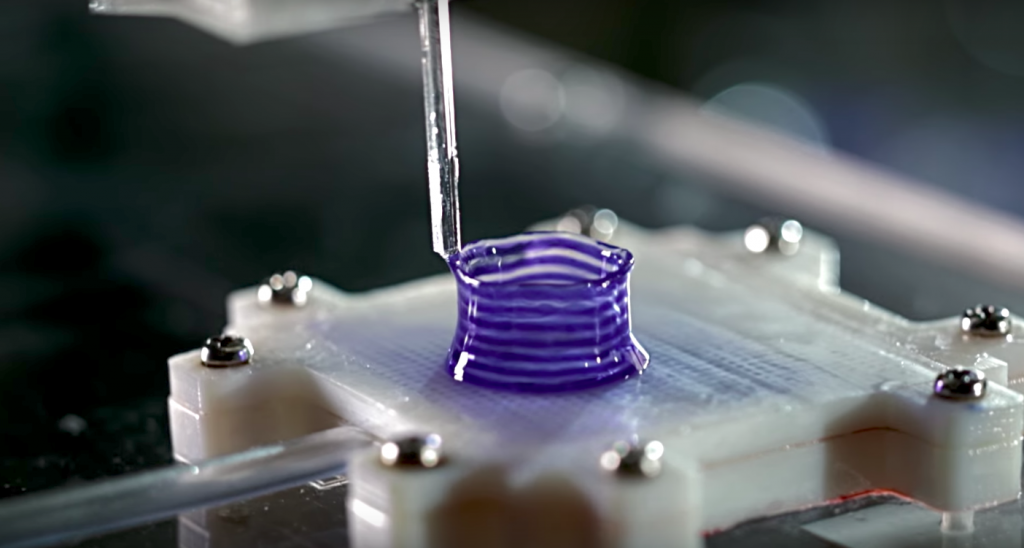

The lab is set to occupy a 100 square meter space within the Trinity Biomedical Sciences Institute (TBSI), including an area for handling live matter and cell cultures.

“Transforming healthcare delivery for patients and consumers through 3D printing technology requires collaboration with experts from around the world,” concludes Wim Appelo, vice-president supply chain, Johnson & Johnson Medical Devices Companies.

“Our work with AMBER will advance opportunities to design and deliver a broad range of personalised, bioprinted healthcare solutions for the patients and consumers we serve every day.”

Have TCD, AMBER and Johnson & Johnson demonstrated an outstanding contribution to 3D printing in healthcare? Make your nominations in the 2018 3D Printing Industry Awards.

Want to design this year’s trophy? Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your design now to win a 3D printer.

For more biomedical and dental news subscribe to the most widely read newsletter in the industry, follow us on Twitter, and like us on Facebook.

Featured image shows a concept image of the inside of Trinity Biomedical Sciences Institute. Image by Donal Murphy/Armstrong