Further to the company’s announcements of four senior appointments in three months and being honoured by New Economy Magazine for 3D printed healthcare innovations, advanced propietary materials and 3D printing company Oxford Performance Materials (OPM) has commenced an in-depth extensive research program with Yale University. The program will include ten projects that will utilize Yale biomedical expertise and OPM’s experience with its proprietary poly-ether-ketone-ketone ‘OXPEKK’ formulation.

The ten projects include remarkable devices supporting direct tissue attachment for cranial and facial surgery; 3D printed PEKK prosthesis’ for rib replacement; 3D printed PEKK devices to deliver therapeutics for improved vertebral fusion; and devices to deliver antibiotics to combat implant associated infections. The outcomes will expand upon OPM’s existing ground-breaking range of polymer prosthetics: Cranial maxillo-facial for craniotomy, orbital reconstruction and mandibular reconstruction; none-load baring upper extremity; small bone for hands and feet; and ‘per customer’s design.’

Dr. Adam Hacking, PhD, Chief Scientific Officer, Oxford Performance Materials enthused: “We are excited to announce this broad collaboration with Yale’s distinguished team of biomedical engineering and clinical experts. Our comprehensive medical device development platform will support the innovation and dedication to improving patient care for which Yale and its faculty are recognized. Together, we foresee the development and delivery of new medical technologies and applications in ways that were previously not possible. OPM has made significant progress with our PEKK-based platform, and we are continuing to advance this technology to improve patient outcomes with our partners at Yale.”

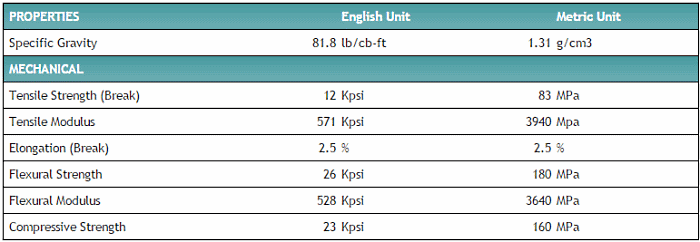

Professor Mark Saltzman, PhD, Yale’s Goizueta Foundation Professor of Chemical and Biomedical Engineering and Chair of Biomedical Engineering expanded: “PEKK is biocompatible, radiolucent, strong and durable. 3D printing enables the facile fabrication of complex geometries. In combination, these technologies present new and previously unavailable opportunities to develop and deliver customized, patient-specific therapies that are also economically viable. We are looking forward to working with Dr. Hacking and his team at OPM on these joint research initiatives that are designed to improve how personalized medicine is developed and delivered to patients.”

In 2013 OPM became the only company to receive FDA clearance to manufacture 3D printed patient-specific polymeric implants for its cranial prostheses line and received a a $3.2 million loan from the Connecticut Department of Economic and Community Development supported the expansion of OPM’s South Windsor, Connecticut manufacturing facility. Connecticut Governor Dannel P. Malloy stated: “This is how innovation is fostered in the 21st century economy, and we are proud to support both Yale and OPM as they embark on this groundbreaking research right here in Connecticut.”