WASP has announced the launch of its new Delta WASP 4070 TECH 3D printer.

The self-proclaimed “jewel of Italian additive manufacturing” comes packed with a number of industrial-grade features that make it suitable for aerospace, automotive, medical, and research applications. Characterized by its ability to print the notoriously difficult PEEK polymer, the FDM system has a maximum nozzle temperature of 500°C and a heated bed capable of maintaining 300°C.

To complement the new machine, WASP will also be offering a PEEK 3D printing service, whereby the company’s engineers will assist customers in choosing materials and refining their process parameters.

Delta FDM printing with WASP

The Italian manufacturer already has an extensive portfolio of extrusion-based machines featuring large build volumes. The original ‘Delta Family’ of 3D printers feature the delta coordinate setup, where the stepper motors operate in a triangular formation to closely control the XYZ coordinates of the nozzle. These printers start at 2,370EUR and mainly print thermoplastics such as PLA, ABS, PETG, and PA carbon.

The ‘Clay’ series of 3D printers feature the same delta coordinate setup but focus on printing with ceramic materials rather than pure polymers. These machines start at 3,000EUR and are typically capable of printing up to about a meter in height.

Finally, the ‘Industrial’ series of 3D printers, with their delta setup, specialize in printing high-performance engineering materials. Starting at 3,490EUR, these systems are compatible with a number of obscure filaments such as ASA, high-impact PS, PPS, and PMMA.

The Delta WASP 4070 TECH

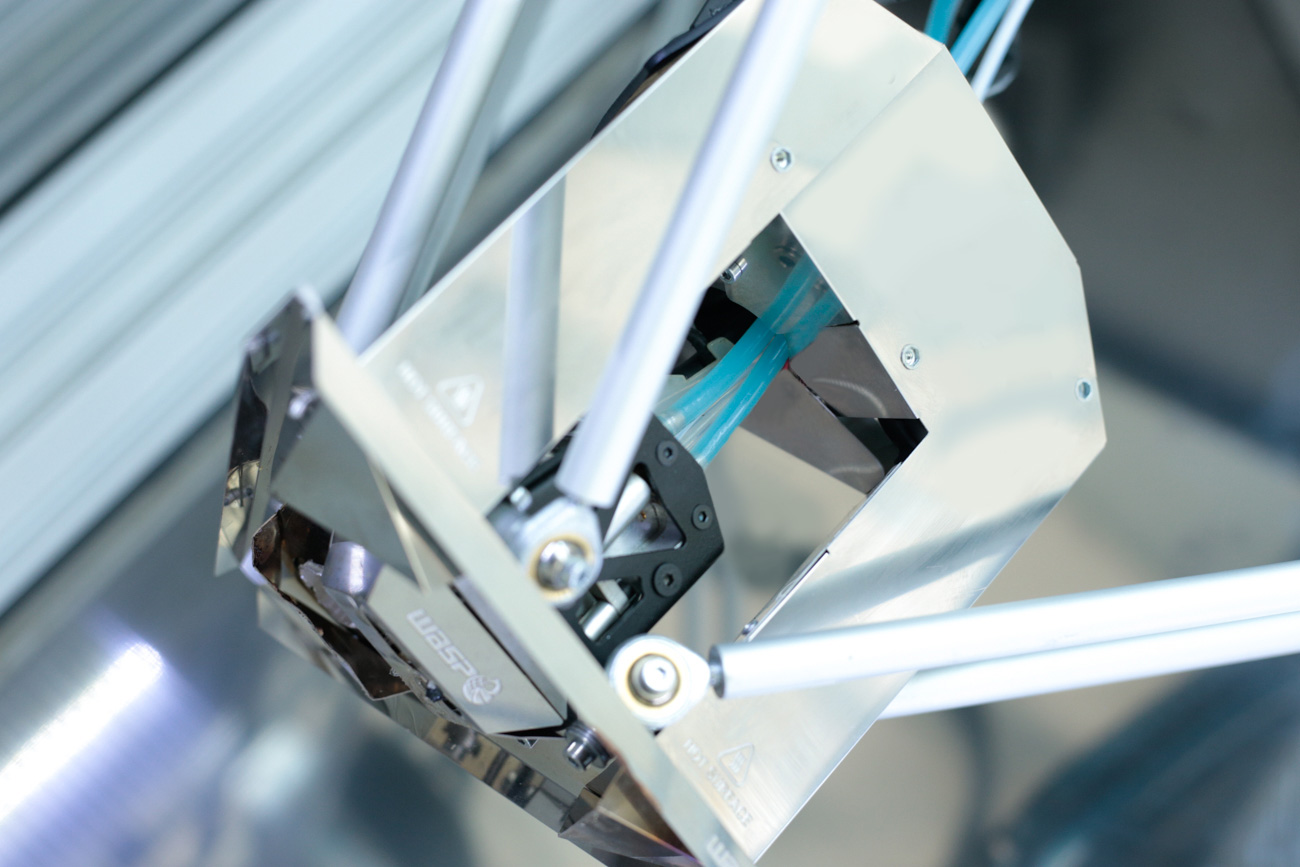

Intended to fill the PEEK-shaped niche, the 4070 TECH features the company’s new water-cooled extruder, with a full-metal nozzle capable of 500°C. The machine’s proprietary FIRECAP system also heats the build chamber up to 300°C, resulting in stress-free internal structures and uniform material crystallization – even on large scale parts.

WASP has also kitted out its new machine with a proprietary inline drying system, which provides active temperature control for the filament as it is being extruded. By dehumidifying the material, users are given better surface quality and mechanical properties on their parts. Automated bed leveling and a controlled vacuum system under the bed also allow the user to substitute out the build plate at will, enabling easier part removal.

On the firmware side of things, the 4070 also has an in-built gcode analyzer that checks print jobs for errors and an ‘auto check system’ capable of self diagnosing issues with the printer’s functions. To top it all off, Wi-Fi connectivity allows for remote management and monitoring while an on-board camera lets users create timelapses of their high-performance parts.

Technical specifications and pricing

Below are the technical specifications for the Delta WASP 4070 TECH, with the full set soon to be available. Readers interested in purchasing the machine should visit the WASP store page for a quote.

| Nozzle temperature | 500°C |

| Bed temperature | 300°C |

| Extruder | Water-cooled |

| Wi-Fi | Yes |

| In-built camera | Yes |

| Bed leveling | Automated |

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Delta WASP 4070 TECH. Photo via WASP.