Researchers from Tufts University have used scaffolding to encourage the development of three-dimensional brain-like tissue that can be used to study brain injuries and genetic disorders. And, ultimately, this could have a big impact on 3D bioprinting.

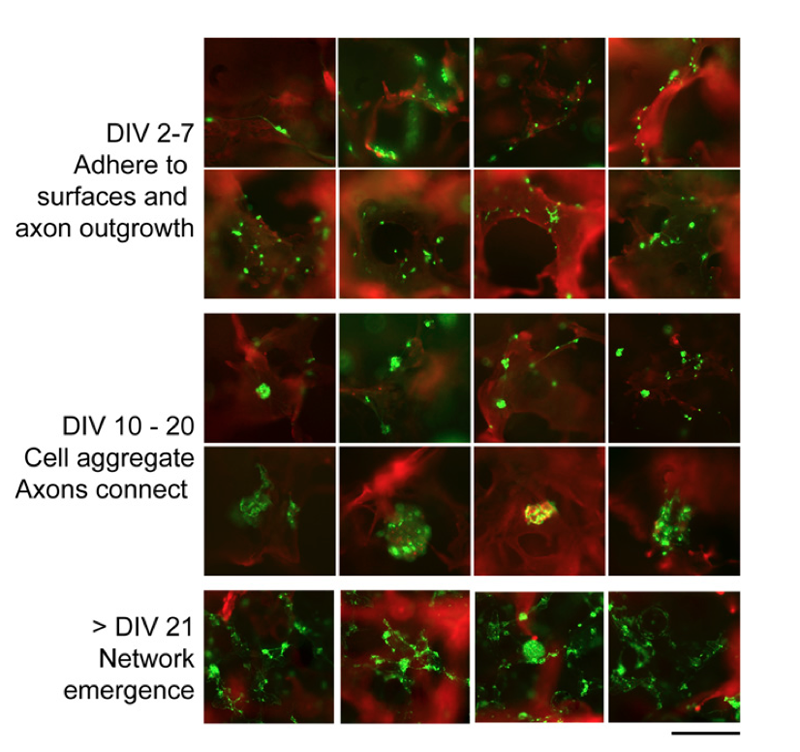

Brain tissue is the most difficult type of organic matter to create in a lab setting, typically lasting for less than a day before dying; however the new bioengineered brain tissue from researchers at Tufts has remained viable for several weeks and develops complex neuronal activity that mimics living brain tissue. It even organized itself into brain-like structures and created distinct grey and white brain matter, as detailed in their report “Bioengineered functional brain-like cortical tissue”, published in Proceedings of the National Academy of Sciences (PNAS).

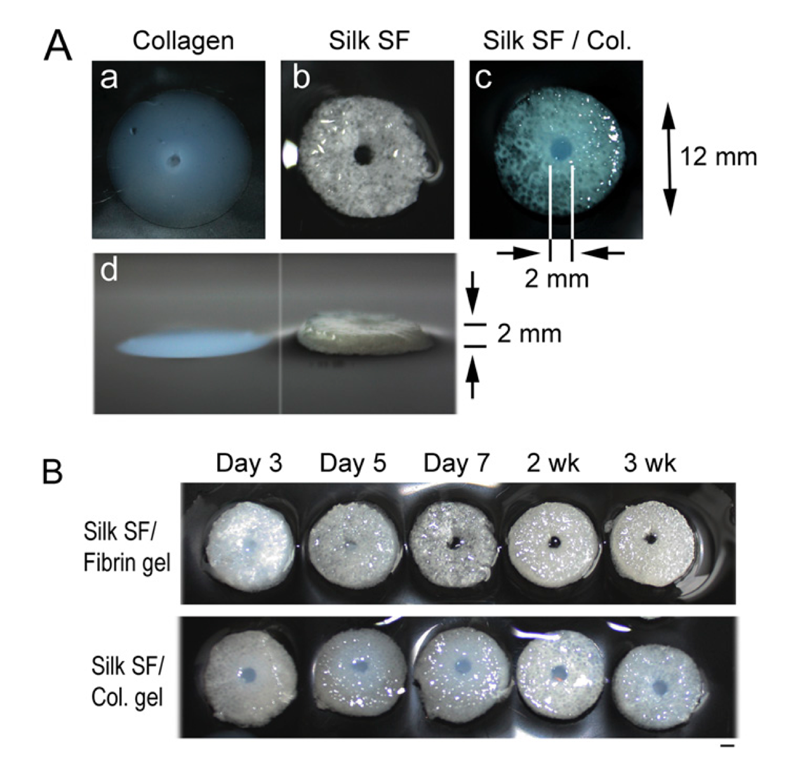

In previous attempts to create lab grown brain matter, a hydrogel was used to encourage tissue growth, but this was limited in size and only developed two-dimensional structures. In order to encourage three-dimensional growth, the Tufts team used a collagen gel and a bio engineered silk protein to create a porous scaffolding structure. This allowed the white brain cell material to fully develop and created a clear distinction between white and grey brain matter, including sending electrical impulses to each other.

Under close examination, the 3D brain matter showed the same sorts of electrical activity that a fully functional brain would show. This made it possible for the researchers to carry out several experiments intended to examine how the brain reacted to different sorts of drugs. They also caused damage to the tissue,to mimic a traumatic brain injury. Altogether, these experiments were intended to compare their results to similar experiments carried out with animal brains. Early results showed promising similarities between both experiments, meaning that their bioengineered tissue could create a viable alternative to the use of animals in these sorts of tests.

With lab-created brain matter this complex and viable for such a long period of time, the researchers are able to follow the tissue response to the initial damage over time, as well as how the matter begins to repair and reconstruct itself after injury. This could drastically improve the amount of information we are able to learn about how the brain reacts after receiving damage, and hopefully lead to new advancements on reversing traumatic brain injury.

At the same time, this research may have substantial implications for the field of 3D bioprinting. Though not specifically used in this case, the practice of creating a three-dimensional scaffold led to more viable tissue, the very reason companies like Organovo took to bioprinting in the first place. It’s possible that, with bioprinting, researchers could create a structure modeled accurately after actual areas of the brain. 3D printing would also allow some enterprising company to more rapidly construct assays of brain tissue for the purposes of drug testing, in the way that Organovo is hoping to do with their liver cells. And, needless to say, this research is one more piece of the ultimate, full organ printing puzzle.