A white buffalo exists — though it is a rare animal. It is a fitting metaphor for ceramics 3D printing in a world dominated by tecnoplastics and metal alloys. That is why Nebraska based Tethon 3D chose its name, which means white buffalo in the language of Omaha Native Americans. It is also a company that 3D prints some amazing ceramics sculptures.

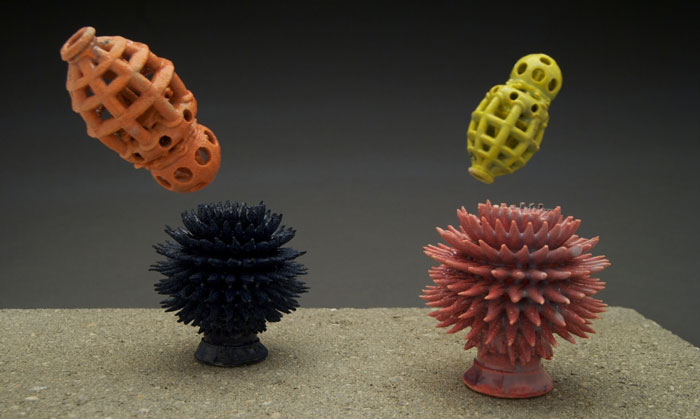

To better convey the message the company published some original 3D printed ceramics work. These were produced using ZPrinter 310 and 510 along with different mixes of Tethon3D’s clay powder.

Tethon3D explained that some of the issues in making the sculpture relate to the materials; ceramic stoneware, porcelain and earthward shrink during firing, as does traditional clay. Pieces can have single walls as thin as 1 mm but the entire object cannot be 1mm thin all around because it undergoes an intense pressure – somewhat like a strong gravitational pull – in the kiln.

After 10 years of development, the process has been fine tuned. In ZCorp technology, only the binder liquid goes through the printhead, hydrating the ceramics powder to retain the desired shape. The excess powder is cleaned off and then the object is glazed and fired. All materials work with most glazes but have different characteristics: stoneware is more durable though it needs an additive to look white, porcelain is pure white but delicate. Earthware requires low temperatures and can be made to appear red. Most of all, being fired at 1000°C to 1200°C ceramics are much more heat resistant than plastics. Most of all it can be a truly artistic material in a world of materials that all look very similar. Kind of like a white buffalo.