Many are saying that the next big evolution to take place in 3D printing will happen in terms of materials, with the 3D printing materials market to surpass $1 billion in the next five years, according to MartketsandMarkets. We’ve already begun to see a number of exciting materials released for desktop FDM/FFF 3D printers, with the most recent being a graphene-PLA composite announced by Graphene 3D Labs. Last year, too, saw a number of filaments filled with carbon nanotubes for added strength. Today, however, taulman 3D, one of the original innovators in the field of desktop 3D printing materials, has unveiled a new material called Alloy 910, which is designed to be extremely strong, without any of the composite fillers.

Made in development with chemical companies, extrusion manufacturers, and taulman 3D, as well as input from the 3D printing community, Alloy 910 is meant to be the perfect filament for high-performance 3D printing. According to taulman, the material has “a combined tensile strength higher than the strongest co-polyesters, the durability of Nylons, a shrinkage factor that rivals our t-glase, a vast range of chemical resistance, and a 95° C working range.” At the same time, it’s designed to be used with relative ease, printable at 245° C. taulman provides the complete material specifications as follows:

- Tensile Strength = 8,100PSI +

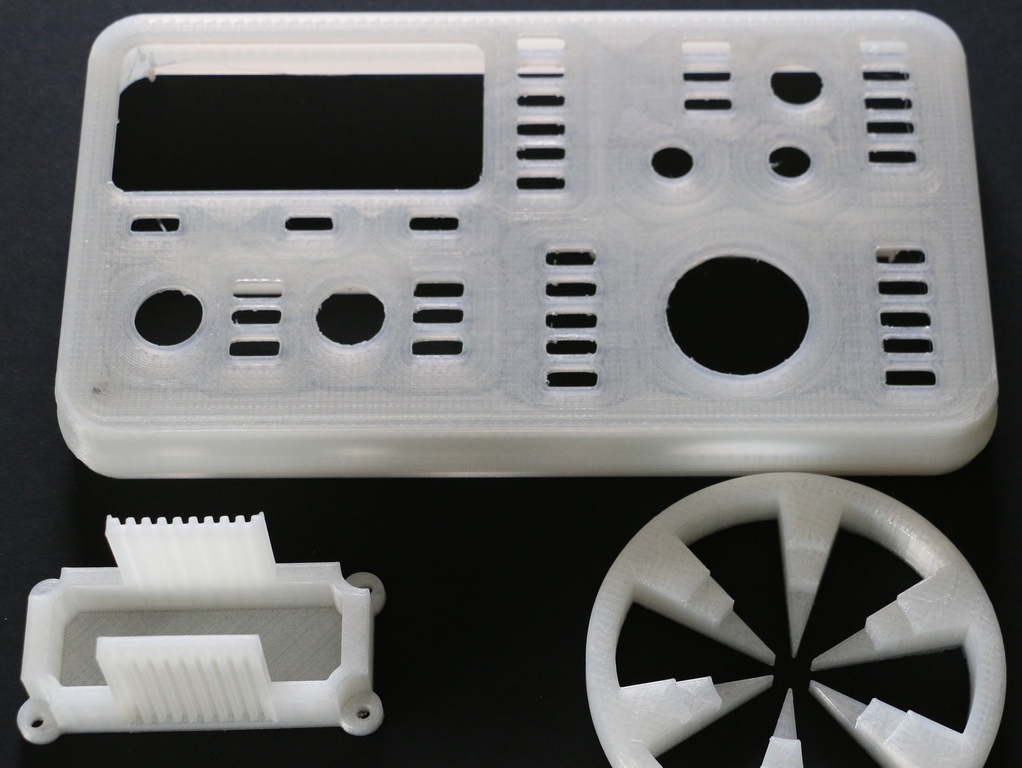

Electronics enclosures that are “drop-test ready”. - Modulus PSI = 72,932

- Max Elongation at break = 31%

- Print Temperature = 245° C

- Nozzle size = Any – There are no particulates or additives in Alloy 910

- Tg = 90° C

- Shrinkage = 0.0031 in/in

- Transmission = 50%

- Color = Subtle Amber – May be dyed with acid based dyes.

And, though Alloy 910 has a tensile strength greater than 8,100 PSI, this is accomplished without any added-in materials, such as the aforementioned carbon nanotubes or carbon fibers. No composites or filler. In other words, this is a pure plastic, so that it is very versatile, but also has wide universal appeal and requires no specialty nozzles. To print the material, all that’s needed on a printbed heated up to 45° C is a coat of PVA and, on a cold bed, BuildTak with some PVA.

Tom Martzall, the founder of taulman 3D, tells me that due to its high strength, Alloy 910 has a lot of great applications for building industrial parts and robotic components. Its low friction also makes it ideal for creating articulation systems, perhaps for Simpson-style RepRap? Tom also says that his company spent the weekend at the Midwest RepRap festival, where loops of Alloy 910 were handed out to the RepRappers in attendance. So, soon, we’ll be able to hear from the 3D printing community itself just how versatile and valuable this material is. If you’d prefer not to wait to hear from them, Alloy 910 is available in 1.75mm and 2.85 mm spools is already shipping worldwide.