For those seeking to fully-optimize the 3D printing process and produce parts with the highest level of finish and minimal material wastage, simply using an out-of-the-box machine is no longer enough.

That’s why an increasing number of system manufacturers have launched accessory lines to complement and build on their existing offerings, and Polish printer producer Sinterit is no exception. According to the company, its advanced range of add-ons, including an automated powder sieve, platform, and ATEX vacuum cleaner, now provide an “all-in-one solution” for its customers.

“For us, being “Sinterit” means a lot more than producing 3D printers,” said Maxime Polesello, CEO of Sinterit. “Our vision is to promote additive manufacturing for a more innovative and sustainable world. With this in mind, we are focused on delivering the best user experience and solutions that are not only innovative but sustainable as well.”

“We aim to make high-performance SLS solutions accessible to all professionals.”

Sinterit’s “all-in-one” 3D printing solution

Sinterit is a manufacturer of desktop Selective Laser Sintering (SLS) 3D printers, and its current range comprises the Lisa and Lisa PRO machines. Both systems are capable of sintering a wide range of powder materials, including PAs and flexible TPUs, into parts with complex geometries for use within a wide variety of end-use applications.

Although Sinterit’s existing Lisa line is generally geared towards accessibility, the company also provides a range of accessories to compliment its printers, with its more advanced users in mind. Sinterit’s powder sieve, for instance, is designed to automatically sift through used powder, making it ready for refreshment and reuse.

Using electroformed sieves to filter a powder’s particles has been proven to provide even distribution, and small particles can even give parts enhanced strength by creating a higher packing density. While it’s still possible to separate SLS materials using woven wire sieves, the process is less precise, time-consuming, and generally less productive than automatic alternatives.

Sinterit says its machine sifts powders “like a good chef sifts flour,” yielding lump-free materials that can ultimately be used to produce parts with an improved level of surface finish. The compact device, which measures just 60 x 34 x 30 cm, cleans any powder that’s recovered from the print bed or overflow bin.

The resulting processed materials are then ready to be remixed with fresh powder and reused through Lisa 3D printers. As a result, Sinterit’s sieve not only accelerates a potentially time-consuming process, but it also reduces the prospect of material wastage, providing users with a productive, eco-friendly processing unit.

Creating an additive product ecosystem

SLS production provides users with numerous advantages, including creating support-free parts in freeform geometries, amongst others, but powder can cause a problem: mess. 3D printers need to be cleaned after a build to avoid cross-contamination, and there’s often a fair amount of excess powder left on the feed and print beds after processing.

Although ordinary vacuum cleaners aren’t sufficient for the task, there are several options on the market for the 3D printing users out there. Sinterit’s ATEX Vacuum Cleaner has been designed to make powder recovery quick, easy, and safe to do, with the overall aim of helping customers to accelerate their manufacturing workflow.

The machine is ATEX certified, meaning that it can safely pick up any potentially explosive powders. It can recover up to 100 percent of excess material in less than 10 minutes. What’s more, the system also features a powder separator, which picks up unsintered powder from the print bed, and puts it into a dedicated 12-liter container.

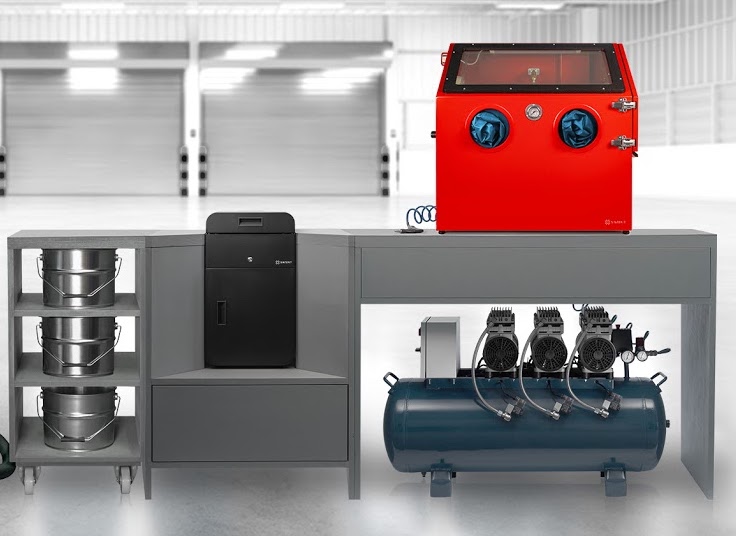

The separated powder can then be poured into Sinterit’s automated sieve, ready to be re-used on a new build, and this forms the first link in the firm’s product ecosystem. In order to provide a complete solution for its clients, the company also offers a range of post-processing machines in the form of its Sandblaster and Sandblaster XL systems.

Sinterit’s sandblasters enable users to clean small gaps and polish the surfaces of components, yielding optimal end-use parts that are ready to go to market. During the blasting process, the devices can actually be operated with either a fixed nozzle, or be used in handheld mode, depending on what’s convenient for the user.

This feature provides clients with the flexibility to use both hands to manipulate the object if necessary, and ultimately allows them to be more thorough, achieving a higher level of finish. In terms of the original Sandblaster, its small form factor also makes it ergonomic with space, and easy to use too.

As a result, Sinterit’s Sandblaster is similar to its sieve and vacuum products, in that it has been built with convenience, accessibility and functionality in mind.

Stability and space in the workplace

The third and final part of the company’s “complete solution” is its easy-to-assemble platform, custom-made for its Lisa line of 3D printers. Sinterit’s desktop units are already designed to make the best use of available space. Its trolley-like device builds on this by allowing users to move the machine for cleaning or servicing quickly.

Compared to other available printing platforms, Sinterit’s is unique because it features two sets of legs adjustable to different heights. Therefore, users can adjust the platform to make Lisa systems more comfortable to use and provide easier access during vacuuming and post-printing activities.

Once the platform is combined with Sinterit’s automated powder sieve and vacuum devices, Lisa adopters can expect to achieve the fastest, safest and cleanest experience possible from their machines. As a result, although many SLS options are on the market, not many provide the same comprehensive range of performance-optimizing accessories that Sinterit’s do.

Nominations for the 2020 3D Printing Industry Awards are still open; let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our Facebook page.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sinterit’s LISA 3D printer, along with its platform and vacuum cleaner accessories. Photo via Sinterit.