UK aerospace parts manufacturing company Sigma Components has announced that it has received a £140,000 investment from NATEP – National Aerospace Technology Exploitation Programme – to develop 3D printed jet parts and fittings. The government program was set up to invest in business that develops innovative technology for the aerospace sector.

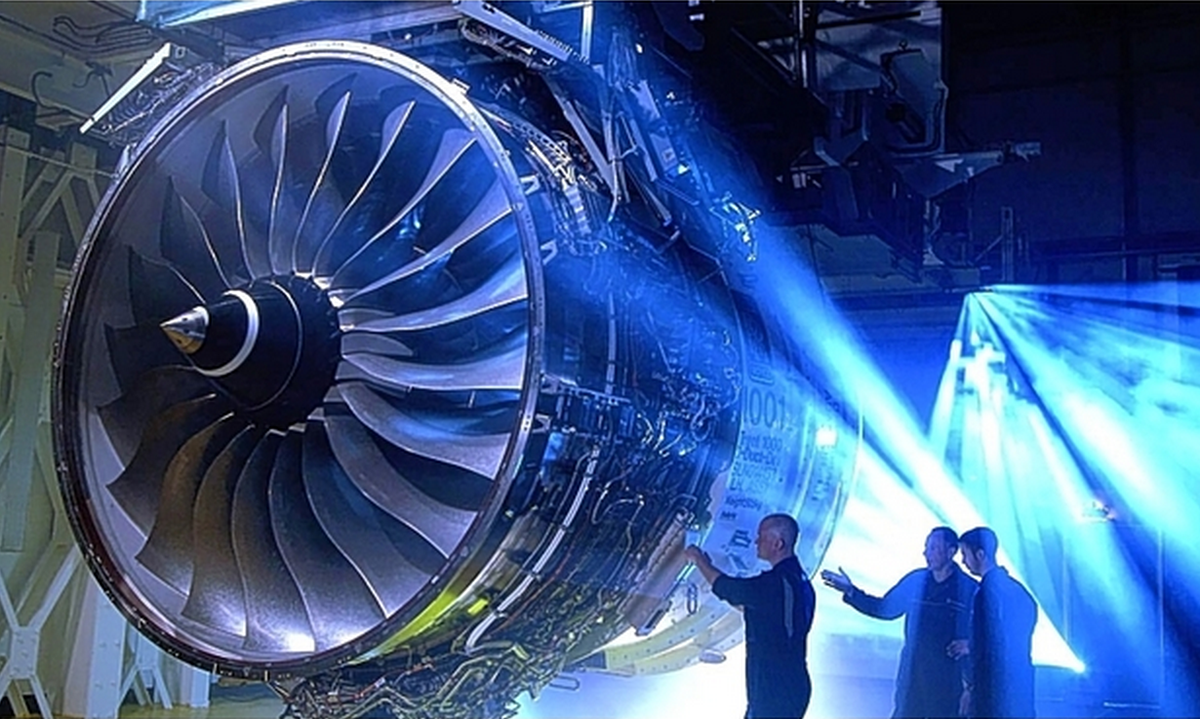

The NATEP investment is supporting a project to research, redesign and develop lightweight pipe end fittings that use 3D printing and additive manufacturing to reduce the weight of traditionally manufactured components and minimise part and manufacturing costs. Sigma is partnering with 3T RPD and Rolls-Royce on the project that is worth over £280,000.

“We’re delighted to have secured funding for the project and to be working with such well-respected partners in the industry,” said Sigma Components director of technology and improvement Mike Andreae. “The UK has long been at the cutting-edge of developments in the aerospace sector and this funding will help us explore the potential presented by new technologies, such as additive layer manufacturing, to improve component design and performance. In a global industry, you have to continuously invest to remain ahead of the competition.”

Located in Hinckley, Sigma Components manufactures high-quality precision-engineered components for the aerospace industry. The company’s involvement with the project is expected to last twelve months and they and their partners are expected to produce 3D printed samples of the end fittings in the approved materials.