One of the most endearing and selfless uses of 3D printing technology within the maker community has been centered on 3D printed prosthetics. From volunteer organizations such as e-NABLE and beyond, may children and adults have rediscovered the use of their hands thanks to the 3D printing community. Although we are off to a quick and heartfelt start, these 3D printed prosthetics often lack in efficiency. In order to help alleviate this issue, one team from the Rice University’s George R. Brown School of Engineering, dubbed Carpal Diem, have developed a testing suite to infer just how well these 3-D printed hands transfer force to the user.

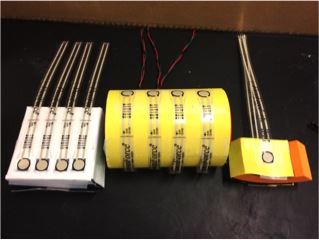

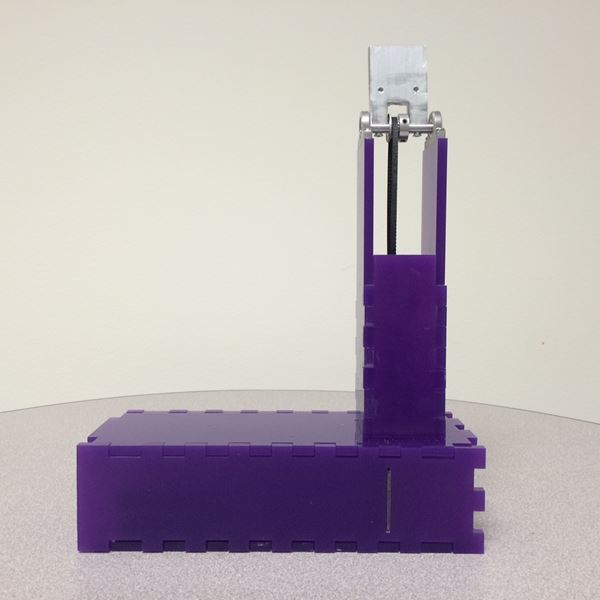

The test is comprised of a number of different components, including a motorized wrist-and-palm assembly, a set of geometric objects with embedded force sensors, and a control program. These sensors provide the computer with feedback on force strength and distribution, which will help show how efficient (or inefficient) each tested 3D printed prosthetic is. Before creating their unique testing process, the Carpal Diem team considered 3D printing their own improved prosthetic hand, but realized that a force-testing device would be much more useful in a field with an abundance of prosthetic designs.

“If a kid has to put in five pounds of force to only get one pound of grip, that’s a lot of lost efficiency because of how these hands are designed,” said Rachel Sterling, a member of Carpal Diem and mechanical engineering student at Rice University. “Until we reach a force efficiency of 100 percent, the hands aren’t going to be useful.”

The testing suite was started by a group of five Rice University students with different engineering backgrounds, including Nicolette Chamberlain-Simon, Michaela Dimoff, Nirali Desai, Rachel Sterling, and Amber Wang. The testing suite started as a senior capstone design project, but has the potential to change the way 3D printed prosthetics are designed. Their testing rig will be displayed at the George R. Brown School of Engineering Design Showcase, which takes place this Thursday (April 14). Going up against over 80 teams, Carpal Diem hopes their testing suite can earn them the $5,000 prize that is up for grabs.

The team also plans to work with e-NABLE as well, offering them the possibility to instantly test different iterations of 3D printed prosthetics on the spot. With the help of Carpal Diem’s mentor, Shriners Hospital for Children-Houston’s pediatric hand surgeon Dr. Gloria Gogola, the team also hopes to put their first testing device prototype, along with an in-depth protocol, into action by the end of this school year.