Valentin Stamate, a researcher at the Transilvania University of Brașov, Romania, has demonstrated a prototype two-stroke engine, 3D printed in 3 different metals. Stamate believes the 3D printed engine to be the first of its kind in the world, and hopes that the production method serves to pave the way for larger 3D printed engines.

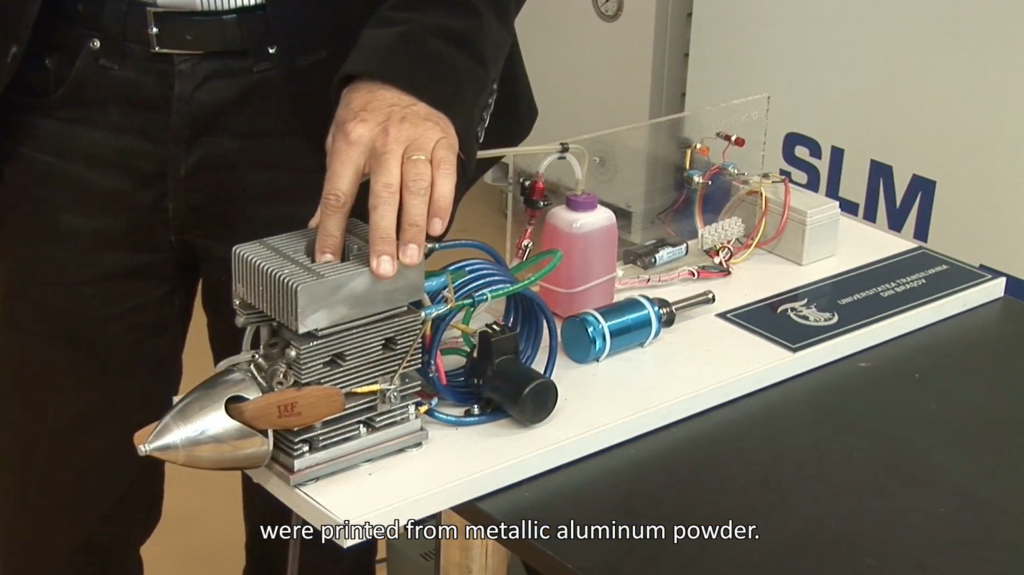

The 3D printed two-stroke engine with propellor in motion. Clip via Universitatea Transilvania din Brasov on YouTube

10 rpm from 10 3D printed metal parts

The engine is capable of achieving 10,000 revolutions per minute and is cooled by an electric motor. At 10 cubic centimeters, the engine would be able capable of propelling small model planes or, if scaled correctly, ultralight aircraft.

Non 3D printed components consist of the propeller, the cone at the nose, bearings, screws, nuts, the spark plug, and the visible plastic tubes and fuel container. Outside of these, the 3D printed components can be broken down into three categories, depending upon the material they are made from.

Aluminium powder was melted to make the engine block, cylinder head and piston. The crankshaft, and the distributor inside the carburettor were both 3D printed using steel powder. And finally, the cylinder sleeve, engine block enclosure, exhaust muffler, motion transmission bar, and the remaining carburettor are made from bronze-impregnated steel powder.

Reducing the cost of prototyping

As explained by Stamate in a video walkthrough of the 3D printed engine prototype, selective laser melting (SLM) technology enabled him to create parts at a fraction of the cost of injection molding.

For a prototype of that scale, Stamate estimates it could have taken tens of thousands of dollars to make the molds for each of the parts 3D printed in this process. In this instance, the whole engine cost around €20,000 to make in total, the equivalent of $21,901.

The 3D printed parts were SLM manufactured on a machine from SLM Solutions. Richard Grylls, Technical Director, NA at SLM Solutions, previously told 3D Printing Industry about his visions for the technology as part of our Future of 3D Printing series.

Companies within the manufacturing industry are consistently looking for ways to improve production of parts to bring down the costs. In addition, 3D printing allows designers and engineers to reimagine machine components, often consolidating multiple segments into a single piece.

For more of the latest 3D printing related research news, sign up to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Featured image: Valentin Stamate’s two-stroke propeller engine. Screenshot via Universitatea Transilvania din Brasov on YouTube