Someday in the future, the peel from your fruity snack, or even you leftover coffee granules could be transformed into a new, useful plastic object. The importance of bioplastics isn’t new in a world where we all need to be conscious of the implications of the materials we produce, though its applications within 3D printing have also been just as important.

PLA is already a common printing medium of choice in the world of 3D printing. It’s a strong, durable plastic, though it is known to be brittle. However in the rise of the use of food waste as a part of these bio plastics, researchers are finding that they can explore the flexibility of these new materials as well as other properties. Plastics like this are often thought of having a life cycle, so the ‘cradle-to-cradle’ approach is usually applied to them.

“More than a substance, plastic is the very idea of its infinite transformation; as its everyday name indicates, it is ubiquity made visible. And it is this, in fact, which makes it a miraculous substance: a miracle is always a sudden transformation of nature. Plastic remains impregnated throughout with this wonder: it is less a thing than a trace of movement.” – Roland Barthes, a French literary theorist, philosopher, linguist, critic, and semiotician.

The Digital Matter Intelligent Construction Research Studio (DMIC) as part of the IAAC has been researching this with the intention of of possibly applying their research to adaptive architecture. They wanted to learn more about the world of Bio plastic, as there were already many advantages of the material, such as:

- Paramentric Material

- Affordablility

- Accessibility

- Lightweight porperties

- Non-toxic

- Rigidity / Flexiblility

- Transparency

- Heat Responsive

- Designer / Maker can control properties

- Biodegradable

Their early experiments demonstrated the beneficial properties of the materials as well as the drawbacks. They chose to continue further testing with gelatin as a base, as its properties were most desirable.

From there, DMIC started to investigate how food waste could be incorporated. They wanted to make the very most of what the ethos of reducing, reusing and recycling would provide them with. Most would think of this as a way to restrict creativity and design, but in this case, they have taken this as an inspiration, and it hasn’t limited their research. To go one step further, they focused on food waste that was local to them, such as Orange peel and shrimp peel, as the company is based in Barcelona, Spain.

Cellulose, a substance found in orange peel, is important as a structural component within many cell walls of plants, and it is also the most abundant organic polymer on Earth. Cellulose has a high molecular chain length, and is more crystalline than cellulose, so it can handle higher temperatures before becoming warped and losing its structure in water.

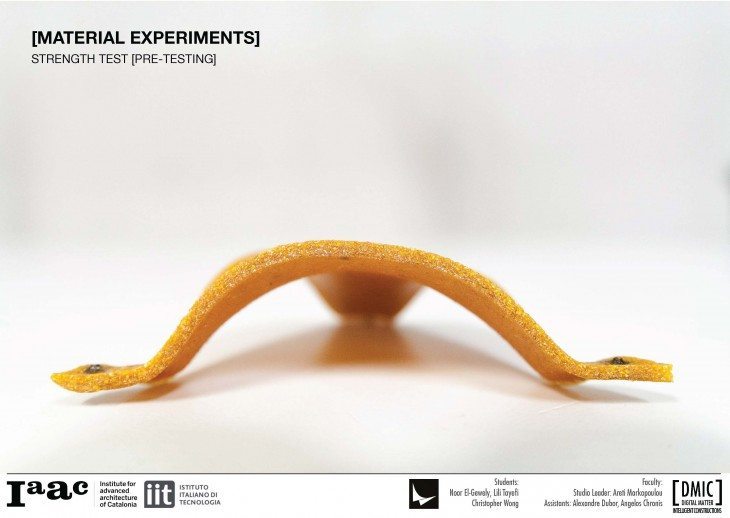

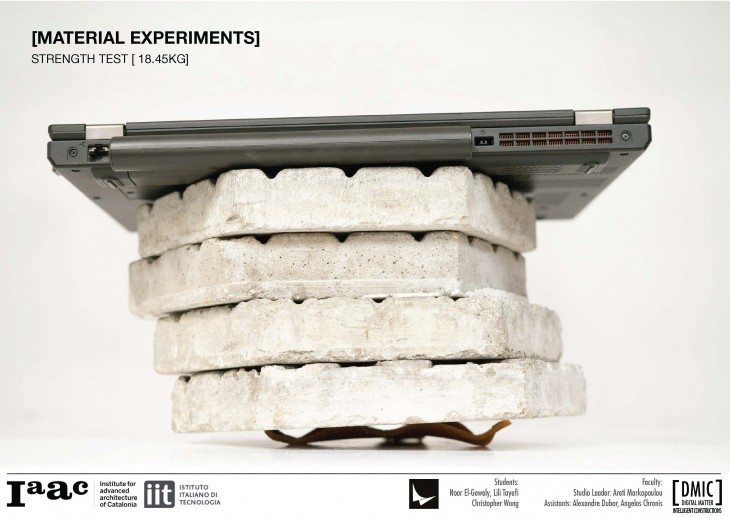

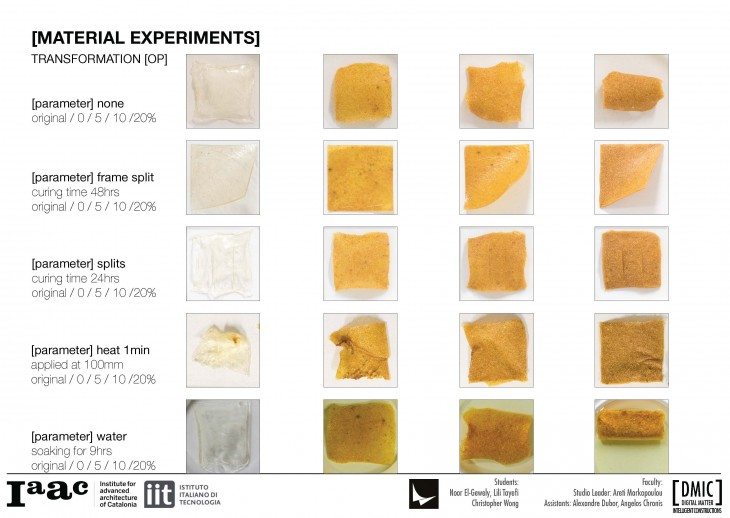

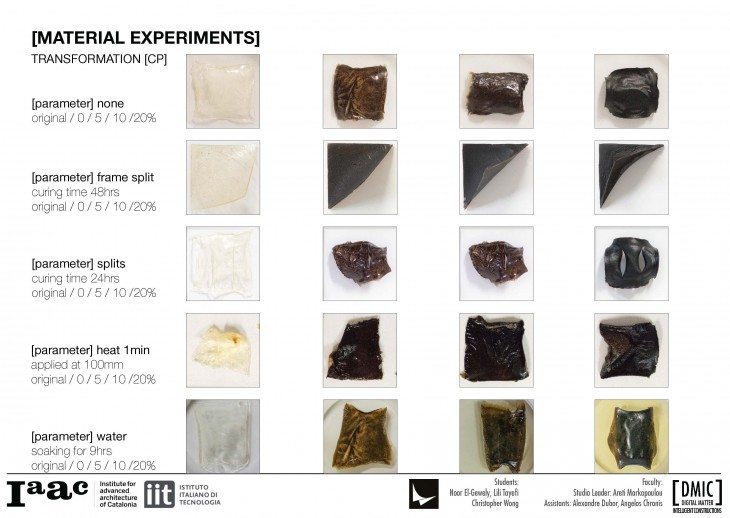

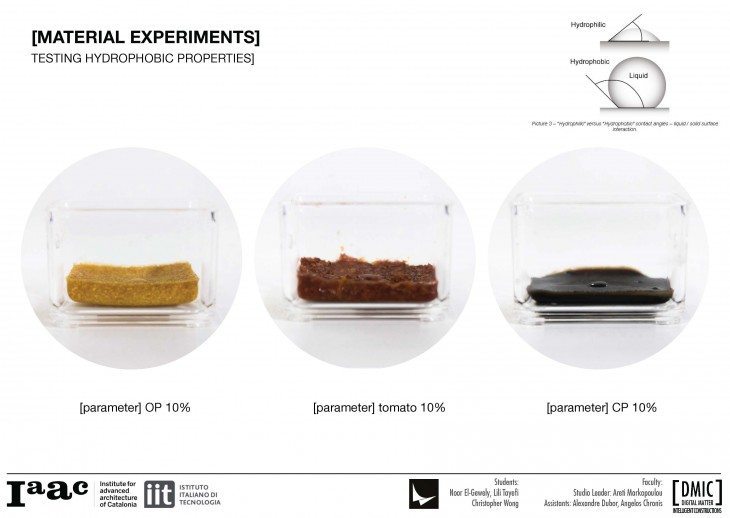

They performed a series of material experiments on the bio-plastics they created to understand how and to what degree the material would transform when put under different strains and stresses.

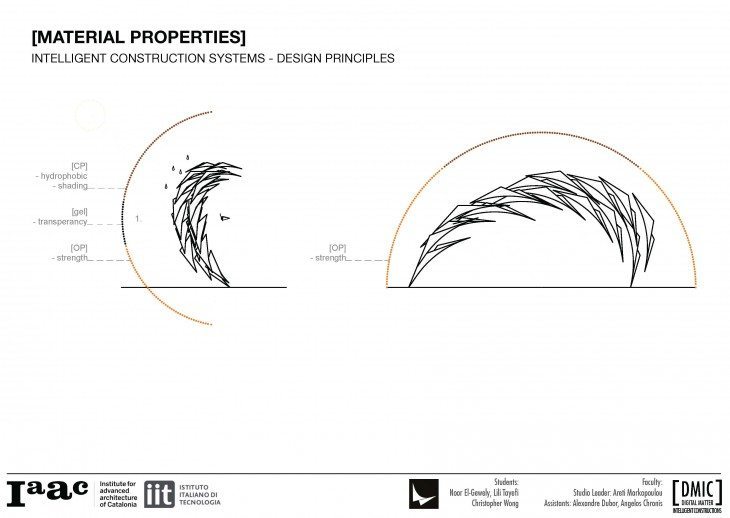

It turned out that the orange peel bio plastic had a good amount of strength as well as higher resistance to heat, whilst the coffee powder bio plastic was water resistant. It was also found that the higher percentage of food waste used in the bio plastic, the more it would bend on its own. Dehydrating the material would trigger it to self-assemble of its own accord, and this was most dramatic in the coffee based bio plastic.

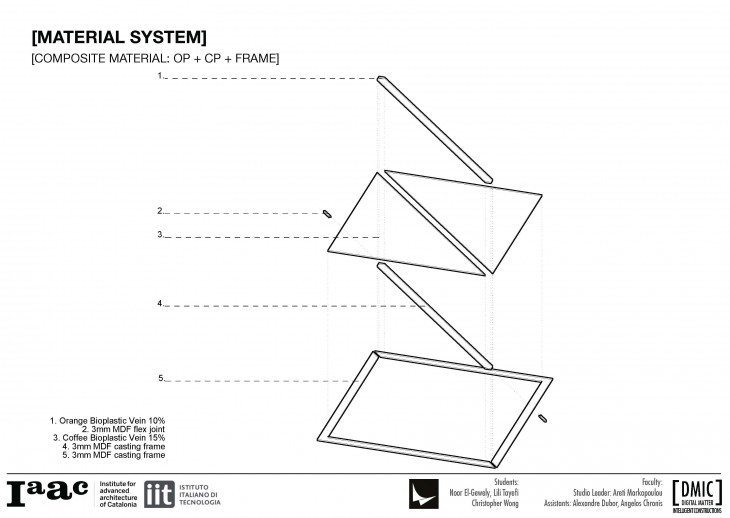

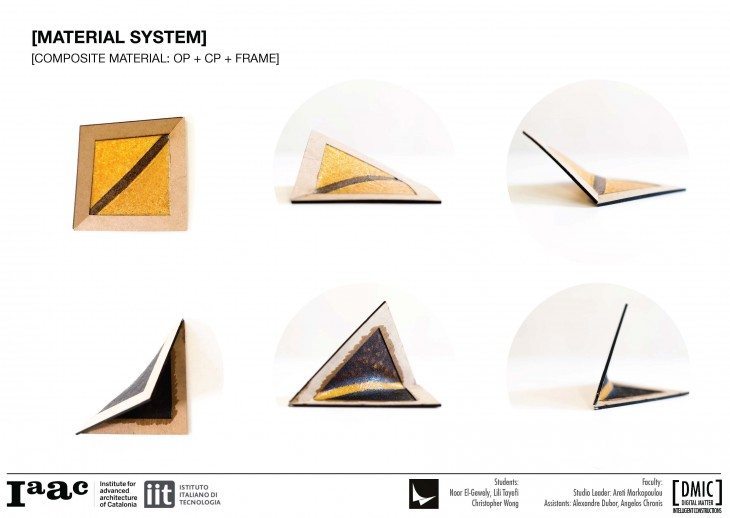

The next stage of testing, was for them to develop a material which combines the beneficial characteristics of the orange and coffee bio plastics to create a composite material.

Depending on each food waste material that was incorporated, the bio plastics would have different properties. Since they were easy to produce, they could fine tune the material performance. Even though at this point they focused mainly on orange peel and coffee as food waste materials, it is possible for other food waste to be used to create bio plastics.

This research is being applied to self sufficient planned cities, with the idea of food waste collection points where the waste would be taken and developed into plastics.

What about 3D printing?

Like most plastics, these bio plastics can be 3D printed. Imagine printing what would have been your compost into a part of a building? These plastics can also be applied to objects on a smaller scale too, so what about printing your own gadgets from rubbish that would have rotted on the compost heap?

This is all very exciting stuff, or exciting rubbish?

PIEL VIVO/BIO-PLASTICA – Material Explorations is a project of IaaC, Institute for Advanced Architecture of Catalonia, developed at Master in Advanced Architecture in 2015/2016 by:

Students: Noor El-Gewely, Lili Tayefi, Christopher Wong

Faculty: Areti Markopoulou, Alexandre Dubor, Angelos Chronis

With help from: Manuel Kretzer, Athanassia Athanassiou, Ilker Bayer