After realizing that I was seeing the same name at the heads of papers and projects that I was a big fan of – the Open Source Optics Library, 3D Printers for Peace, and a paper on the cost savings of the use of RepRap 3D printers in the home – I decided that Dr. Joshua Pearce was quickly becoming a hero of mine and that I wanted to interview him.

In this interview, the scientist/engineer/author/Maker/good Samaritan discusses the various projects that his lab at Michigan Technological University is pursuing, his hopes for 3D printing in the future, and some issues preventing the progress of technological development and, thus, environmental sustainability and poverty alleviation. Highlights include: a solar-powered, portable RepRap and arguments for the detrimental effects of IP.

3D Printing Industry: Because 3D Printers for Peace was the first project of yours that caught my attention and got me interested in your work, let’s start there. Where did the idea for Printers for Peace come from?

Dr. Joshua Pearce: 3D Printing Industry readers are already well acquainted with the fantastic and overwhelming beneficial applications of 3D printing. Yet printing illegal plastic guns was getting so much press, that 3D printing was being darkened in the public eye and our elected representatives were seriously discussing laws against 3D printing, background checks for owners and other legislation that would have a chilling effect on the industry and home users alike. What we hoped to do with the contest was nudge the dialogue about 3D printing back to the positive and discuss applications that could be truly uplifting for humanity. We also hoped the contest would generate some great new ideas about 3D printing that might materially benefit the world. It is hard to say what our government will do when it is closed, but I think for the latter goal we were successful.

3D Printing Industry: We’ve covered the winners of the contest. Can you tell us how they were selected and why they won?

Dr. Joshua Pearce: The entries were all judged for technical viability, innovation, peace considerations, concept validation and presentation. The three winners all demonstrated printable designs that were not only eminently “doable”, but also had a real shot at making a significant impact in the world.

3D Printing Industry: How did you first get involved with 3D printing and how did you become such an active advocate of the technology?

Dr. Joshua Pearce: Working with students to design solar-powered covers for laptops, I was excited to use commercial rapid prototyping for the first time to make their designs. I was disappointed. The costs for the plastic components were insane – costing more than the solar cells. I started looking for better solutions and stumbled on the RepRap project. As many others have done, I was immediately hooked. The idea of a low-cost open-source tool that can make almost anything you can imagine for pennies AND print it’s own components is mind blowing.

3D Printing Industry: You’ve also published a couple of papers that are really quite exciting, including one on the cost savings for the average American household that are possible with a desktop 3D printer and another detailing the open source optics library your lab at Michigan Tech has created. What other studies do you have planned for the future?

Dr. Joshua Pearce: We have several more 3D printer studies in the works:

- We just finished a study that shows that 3D printing at home is not only economic, but also can be better for the environment than conventional manufacturing. We are following up with a similar environmental life-cycle analysis study for recyclebots (waste plastic extruders). We are also working on the technical aspects of recycled filament production and looking for business opportunities for the waste pickers in the developing world to lift themselves out of poverty.

- We have ongoing surface adhesion studies for different filament types so we can move away from heated beds and costly filament.

- We are developing a whole range of different kinds of inexpensive high-end 3D printable scientific tools. I documented both our work and dozens of examples from the community in a book: Open-source Lab, which should be published next month. The idea of open-sourcing scientific equipment is catching on and it is really exciting to see what is going on with groups all over the world like at Tekla Labs.

- We are looking at the mechanical strength of printed parts as a function of material and slicer settings — so we can all start to do ‘real engineering’ with RepRaps,

- We may have a path to metal RepRap 3D printing that costs less than a Makerbot – give us another few weeks…

3D Printing Industry: I read at techfortrade that, at MTU, your lab is working on some other pretty remarkable projects. Aside from trying to bring down the cost of building a RepRap, you’re also working on a solar-powered printer, making filament from recycled materials, and 3D-printed electronics. I also read on the Pearce Research Group site that one M.Sc. student is working on 3D-printed solar cells. How are those projects coming along? When can I expect to 3D print a sustainable 3D printer from recycled materials?

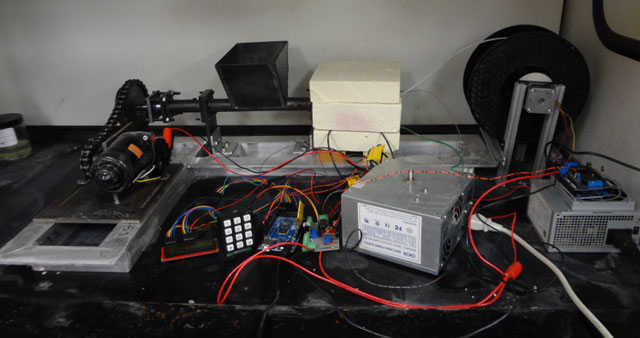

Dr. Joshua Pearce: Our group is about half solar scientists and engineers and half 3D printer researchers and makers so these projects allow everyone to have some fun together. Our solar-powered RepRap prototypes are constantly evolving – the first was a Mendel on a large cart for schools, which is a joint project with Saint Lawrence College in Canada. A second one is a suitcase solar Fold-a-Rap printer. In the works is a MOST delta-bot with flexible solar cells that should fit in a carry on and push the limits on self-reproduction all while driving the costs into the floor.

Our latest work on 3D printable solar racking is extremely promising and we are making major headway with cutting the costs of solar photovoltaic systems because most real research has focused exclusively on the modules. Meanwhile we have a raft of projects with the end goal being total self-reproduction of RepRaps. We are just finishing a parametric open-source syringe pump that will be great for science in general – but also helpful for moving to the next level of materials printing.

It will not be long before we can make a RepRap from waste plastic with solar energy only – it is an emergent technology and I am sure we will see cool versions popping up all over the world.

Dr. Joshua Pearce: My academic background is in photovoltaic technology and the use of nanotechnology to improve the efficiency. Rather than specializing in just one thing as is common now in academia, I like to collaborate with others and combine our skills to decimate problems that need to be solved. Now our group “open sources” our work on Appropedia, the largest wiki for collaborative solutions in sustainability, appropriate technology and poverty reduction. This open-source approach to problem solving has been with me for a while – I ran a Linux server for my friends in college. People from all over the world, who I will likely never meet, have helped our group with our research and pushed technologies forward. There is absolutely no question that we are all smarter than any of us.

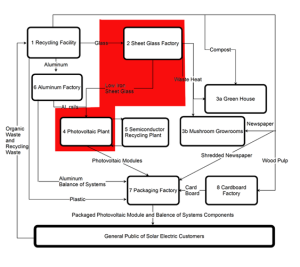

3D Printing Industry: You’ve written about a topic called “industrial symbiosis”. What is industrial symbiosis and how do you see 3D printing fitting into such a model?

Dr. Joshua Pearce: Industrial symbiosis is when companies that are close together work together – usually via exchanging by-products. So for example a glass company provides waste heat to a tomato greenhouse and everyone wins. Industries that appear to have nothing to do with each other can team up like this because they all individually make more money on the exchanges. Better yet it turns out to be really good for the environment because it eliminates what would otherwise be waste.

The aspect of 3D printing I am most interested in is the concept of “distributed manufacturing”, where you literally make products in your home cutting all the transportation, storage, marketing and packaging waste. We can do better by ‘closing the loop’ (just as the smart industrial players do) at home using waste plastic (from either bad prints or plastic containers) as the feedstock through some version of a recyclebot to make filament for our 3D printers. You could do it all with sunlight falling on the solar cells blanketing the roof of your house and really do quite well.

3D Printing Industry: At times, I sense a subversive nature in your writing – things like arguing that “a moratorium should be placed on patenting fundamental nanotechnologies and basic quantum-science applications” or saying “the results of this restricted and closed model of technological development are the widespread poverty and environmental desecration seen around the globe, which is directly responsible for a morally and ethically unacceptable level of human suffering and death.” How do you use scholarly writing and essay writing to reform a system that you are, in some ways, forced to participate in as a member of academia?

Dr. Joshua Pearce: I don’t know if I would classify those statements as subversive. As an engineer and a scientist I am an unashamed proponent of technological progress. It is now well known that imposed intellectual property law hurts progress because it ensures we are retarded by 20 year patent monopolies – a time frame which is laughable when compared to our current rate of innovation. Think about how pathetic a 20-year-old computer is compared to the android smartphone in your pocket.

Some in industry and academia may disagree, but it is pretty easy to sway anyone that is not a Luddite and willing to look at the evidence.

The data is very clear that in all the fields I am familiar with – intellectual property as a concept is getting in the way of technical progress, wasting everyone’s time and in the most egregious circumstances actually killing people by restricting their access to known solutions. This is not really news. If you want to innovate the last place you go is the patent literature to read legal gibberish. Companies now discourage engineers from even looking at it for legal reasons.

In solar it is even more frustrating as there is not a single photovoltaic module on the market that has been able to incorporate even a small fraction of the known technical improvements because of IP-related restrictions.

Most clear for readers of 3D Printing Industry is, of course, 3D printing. It has been around quietly for decades, now it is erupting. Why? Because the shackles came off when it was ‘open-sourced’, unleashing a growing tidal wave of innovation. I do not mean to infer proprietary-based 3D printing companies have been sitting on their hands for years. They have made some progress, but it pails in comparison to what is possible when we ALL get to participate in the game. 3D printer costs plummeted from tens of thousands of dollars to a few hundred as the tech improved. Now, there are dozens of 3D printer companies chomping at the bit waiting for patents to run out on absurdly simple ideas like moving one head out of the way for 2-headed printing. This kind of “invention” is blatantly obvious to anyone that has tried to print with two parallel heads as head #1 smears the work of head #2. IP law simply holds us back.

A growing number of companies are getting it – software giant RedHat earns $1B per year on service while allowing their open-source software to be downloaded for free. Open-source hardware companies are sprouting everywhere, they even formed an industrial association (OSHWA), which want to compete on innovation rather than cower behind intellectual monopolies. We are lucky to see so much of it in the 3D printing world. Growing 3D printer companies like Aleph Objects and Type A Machines use it not only for development, but even marketing. In the end the superior method of technological development will win – those that cling to antiquated notions of lording intellectual monopolies over everyone else will be swept away by free and open innovation. Countries that impose draconian IP laws on their citizens run the risk of being run over by those that let their citizens freely innovate. It will be fun to watch it happen.

3D Printing Industry: One of the questions underlying your work with additive manufacturing seems to be “how can we use 3d printing to save the world?” So, do you think 3D printing can save the world? Will world peace ever happen?

Dr. Joshua Pearce: I think open-source 3D printing can do a lot to bring us all incredible wealth. It can help people in the developing and developed world alike to print themselves out of poverty. It also helps encourage people to flex their creativity and become creators (or makers) again. I think this is really a healthy trend and it is especially encouraging to see students get into it. The number of open designs is growing exponentially and every time anyone shares their flashes of brilliance we all grow richer. The optimist in me hopes this will make a really nice world for our children as the human species matures and rises above petty greed.

I read the news too, so I am not holding my breath.

Looking at everything the good doctor has covered, I believe that he’s doing about as much as a single individual can do to make the world a better place. And, for saying such things, I hope that he considers making me an honorary PhD student at his lab! I don’t know how to build anything, but I’m good at shouting “Eureka!”

To keep up with Hemsley’s developments, follow him on Twitter. To purchase his 3D modeled networks, such as the network of tweets containing the hashtag “OccupyArrests between October 20th, 2011 and November 5th, 2011, here is his store on Shapeways.