Roboze, an Italian based 3D printer manufacturer, has decided to test the thermal capabilities of the PEEK polymer. PEEK is one of the best performing polymers in the world both in relation to mechanical and thermal capabilities. It is a semicrystalline thermoplastic with excellent mechanical and chemical resistance retained at high temperatures. But how hot can it get while retaining its properties? That’s what Roboze set out to discover.

The test

A 25 x 25 x 10 mm block was printed with a Roboze One+400 and was then put into contact with a heated electric resistor. The test involved exposing PEEK to temperatures of 245°C for an extended period of time (8 hours and 30 minutes). It lost only 35% of its properties, compared to the original standard conditions.

The excellent thermal resistance and mechanical properties of PEEK makes it one of the most widely used polymers in 3D printing for high shock applications, and in prolonged heat resistance. The applications that this is beneficial to include aerospace, automotive, defence, mechanical and aeronautic.

About Roboze

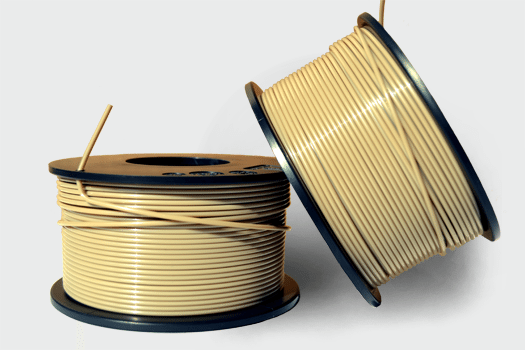

Based in Bari, Italy, Roboze is an innovative 3D manufacturer of the world’s only beltless desktop 3D printers. The company’s one-of-a-kind 3D printing technology enable to product accurate and high quality parts from 12 different materials including PEEK, PEI & CARBON-PA.

Roboze’s vision is to enable professional users advanced yet affordable 3D printing solutions, offering accessibility to high technical materials for advanced applications.