A team from global defense company Northrop Grumman has conducted a study with metal additive manufacturing specialist Optomec’s Aerosol Jet Printing (AJP) technology. Researchers have demonstrated a new method of using AJP to fabricate interconnects on semiconductor chips. After several radiofrequency and reliability tests, the high performance of interconnects proves 3D printing to be a competent alternative to existing semiconductor technologies.

Aerosol Jet Printing (AJP) of electronics

Originally developed to combat limitations in 3D printing materials and surfaces, Optomec’s Aerosol Jet Printing technology is a technique for manufacturing electronics on both 2D and 3D substrates. The metal-based inks used in AJP have the great ability to adhere to readymade surfaces, enabling multi-material objects to be made. This eliminates the need for wire bonding – for example, in electrical connections on 3D stacked die or LED chip fabrication. Capable of making high-resolution electronic circuits and devices, Optomec AJP has been applied to produce strain sensors onto the surface of metal turbines blades, a wireless Bluetooth transceivers and small digital-to-analog converter chips.

AJP electronics present a range of advantages to product development and production, such as cost reduction, rapid prototyping and design flexibility. However, material properties of 3D printed electronic conductors and insulators fail to meet the high performance standards for real-life applications. As a result, 3D printed electronics often suffer from reliability and circuit performance issues.

Performance and reliability of 3D printed interconnects

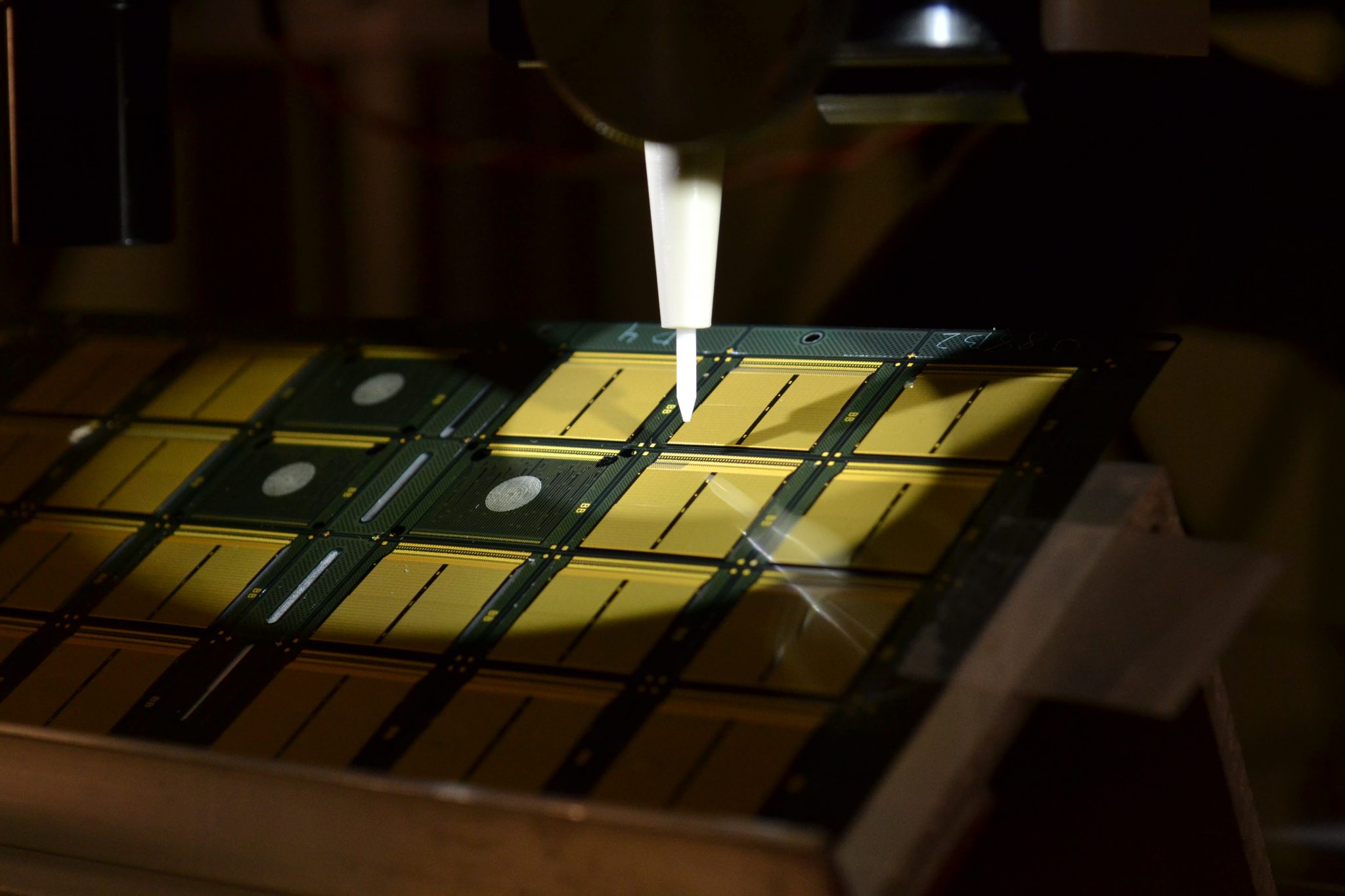

To unlock the potential of AJP, the Northrop Grumman team developed a novel AJP method of fabricating gallium arsenide (GaAs) semiconductors. In the study, the researchers 3D printed dielectric layers and bridge-type gold interconnects on GaAs-based microwave monolithic integrated circuits (MMICs). Radio frequency (RF) testing results indicate that 3D printed interconnects can provide effective and reliable connections. Afterwards, extensive reliability tests, including thermal shock, thermal cycle and current stress test were performed on the MMIC. Subjected to such harsh conditions, the MMICs showed no signs of performance degradation. This proves that 3D printed microwave structures can perform in real-world scenarios.

“The performance and reliability study demonstrates that the low-cost, additive 3D AJ printing is an effective fabrication method for adding highly reliable on-wafer circuit functionalities and features,” Xing Lan, the lead author stated in the research paper. “Additive printing is an excellent complementary technology to existing semiconductor technologies for instantaneous on-wafer circuit prototyping, repair, tuning, reconfiguration, and system on-chip integration with high reliability.”

“Direct On-Chip 3-D Aerosol Jet Printing With High Reliability“ is published on IEEE Transactions on Components, Packaging and Manufacturing Technology. It is co-authored by Xing Lan, Xuejun Lu, Maggie Yihong Chen, Dan Scherrer, Thomas Chung, Evan Nguyen, Rich Lai and Jesse Tice.

For more additive manufacturing news subscribe to our newsletter, follow us on Twitter, and like us on Facebook. Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the chip with AJP 3D printed interconnects. Photo via Optomec.