An end of year burst of activity has seen the announcements of new 3D printing acquisitions from advanced materials company Arkema and German specialty chemicals company Evonik. Meanwhile, 3D printing construction-tech firm Branch Technology has added fleet management company EquipmentShare to its team of investors after closing an $11 million funding round, and collaborative product development platform Wikifactory has raised $3 million in its latest funding round.

Arkema acquires Colorado Photopolymer Solutions

Arkema has announced the acquisition of 3D printing resin manufacturer, Colorado Photopolymer Solutions (CPS), in order to enable its Sartomer subsidiary to further support its customers and partners.

Sartomer specializes in photocure resins and photoinitiators, and the acquisition aims to foster the development of customized turnkey offerings for the 3D printing market. CPS produces formulated photopolymer resins for energy curing technology, and its addition to Arkema’s portfolio will complement Sartomer’s current resin range and expertise.

Completed in early December, the acquisition forms part of Arkema’s strategy to become a pure specialty materials player by 2024. The company recently led a series B funding round for 3D printing resin supplier Adaptive3D shortly after extending its partnership with US-based start-up Continuous Composites to drive the development of its CF3D printing technology.

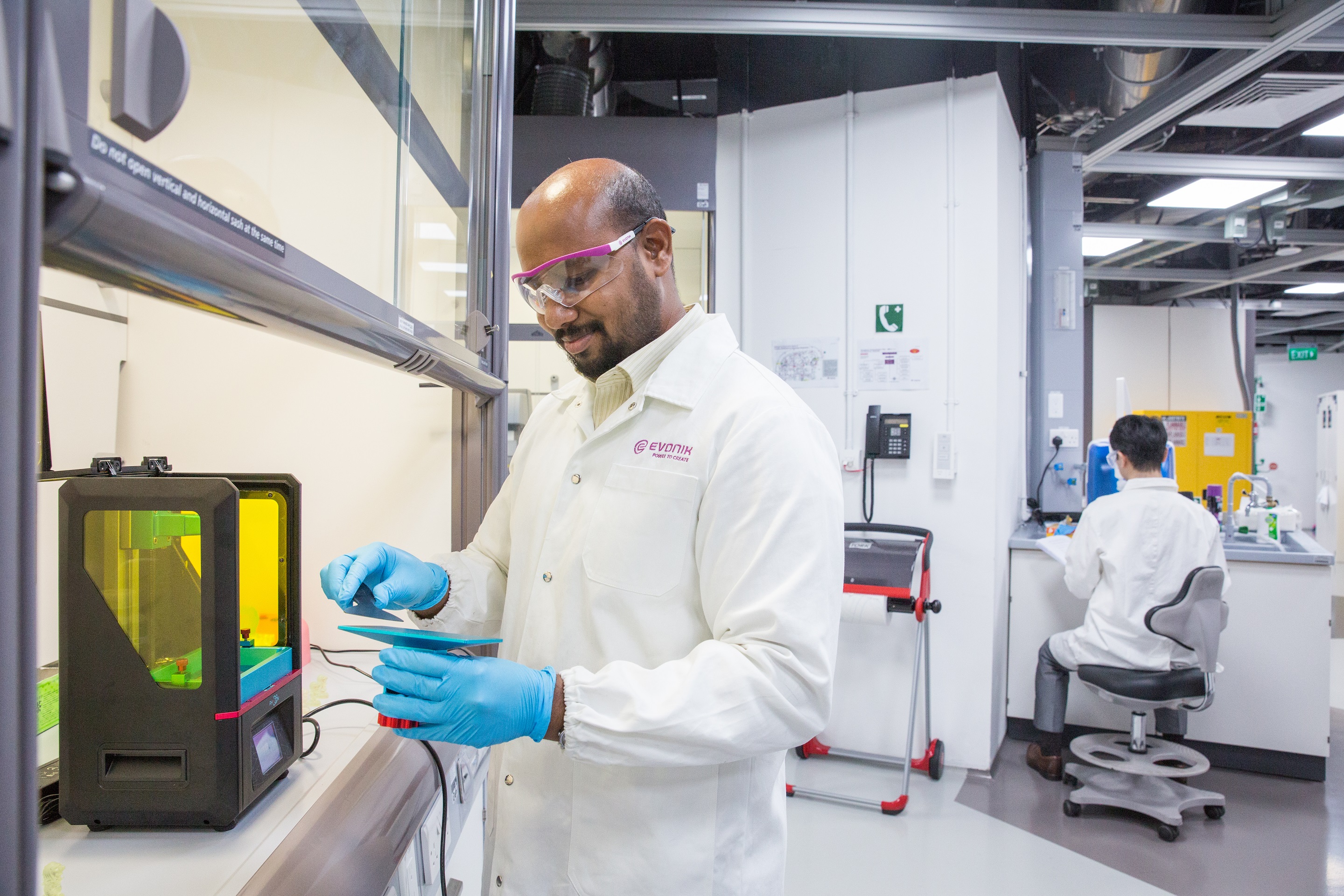

Evonik acquires stake in UnionTech

Evonik’s Venture Capital unit has secured a minority stake in Chinese industrial SLA 3D printer manufacturer UnionTech, and is preparing to introduce a set of new formulations to the market as a starting point of the group’s INFINAM photopolymer product line.

“We expect great technical advances in the field of stereolithography,” said Bernhard Mohr, head of the Venture Capital unit. “Evonik is preparing the launch of ready-to-use materials for this process. Our investment is therefore not only aimed at a profitable financial return, but above all at new insights in the use of this process.”

Mohr expects accelerated market access for Evonik’s new photopolymer products within the Chinese market in particular, and believes the UnionTech investment complements the firm’s existing 3D printing portfolio. The market leader in Asia for ultra-large industrial 3D printers, UnionTech develops printers, supplies printing materials through subsidiaries, and offers 3D printing as a service provider.

Thomas Grosse-Puppendahl, head of the Additive Manufacturing Innovation Growth Field at Evonik, added: “With the coming up introduction of the new products and the current participation in UnionTech, we are expanding our activities as a reliable partner of the industry in the development and manufacturing of high-performance materials for 3D printing to strengthen our business activities along the important photopolymer technology.”

Branch Technology raises $11M to expand enterprise partnerships

Chattanooga-based Branch Technology has closed an $11 million funding round led by EquipmentShare and supported by Brick & Mortar Ventures, Chattanooga Renaissance Fund, and others.

Including its Series A funding round undertaken in 2018, Branch has raised over $22 million to develop and expand its construction-scale 3D printers and product lines. The latest investment will enable Branch to bring in additional industry experts to join its team to expand the firm’s capabilities in building science, software development, and engineering. The company will also seek to scale up its robotic production fleet.

“We are excited about the addition of EquipmentShare to our strategic team of investors and partners,” said Platt Boyd, founder-CEO of Branch Technology. “Together with past investment from Brick & Mortar Ventures, Bonaventure Capital, LaunchTN, and Metaprop, we are collectively revolutionizing the construction industry.”

As Branch expands, it plans to further develop its Cellular Fabrication (C-Fab) composite 3D printing process, which combines robotics, geometric algorithms, and a novel freeform printing technique to produce 3D printed building cladding, optimized composite products, and off-world construction projects.

Mitch Lewandowski, CCO for Branch, added: “This funding supports several enterprise relationships that will officially launch in 2021 and accelerates new joint capabilities that will serve the broader construction market.”

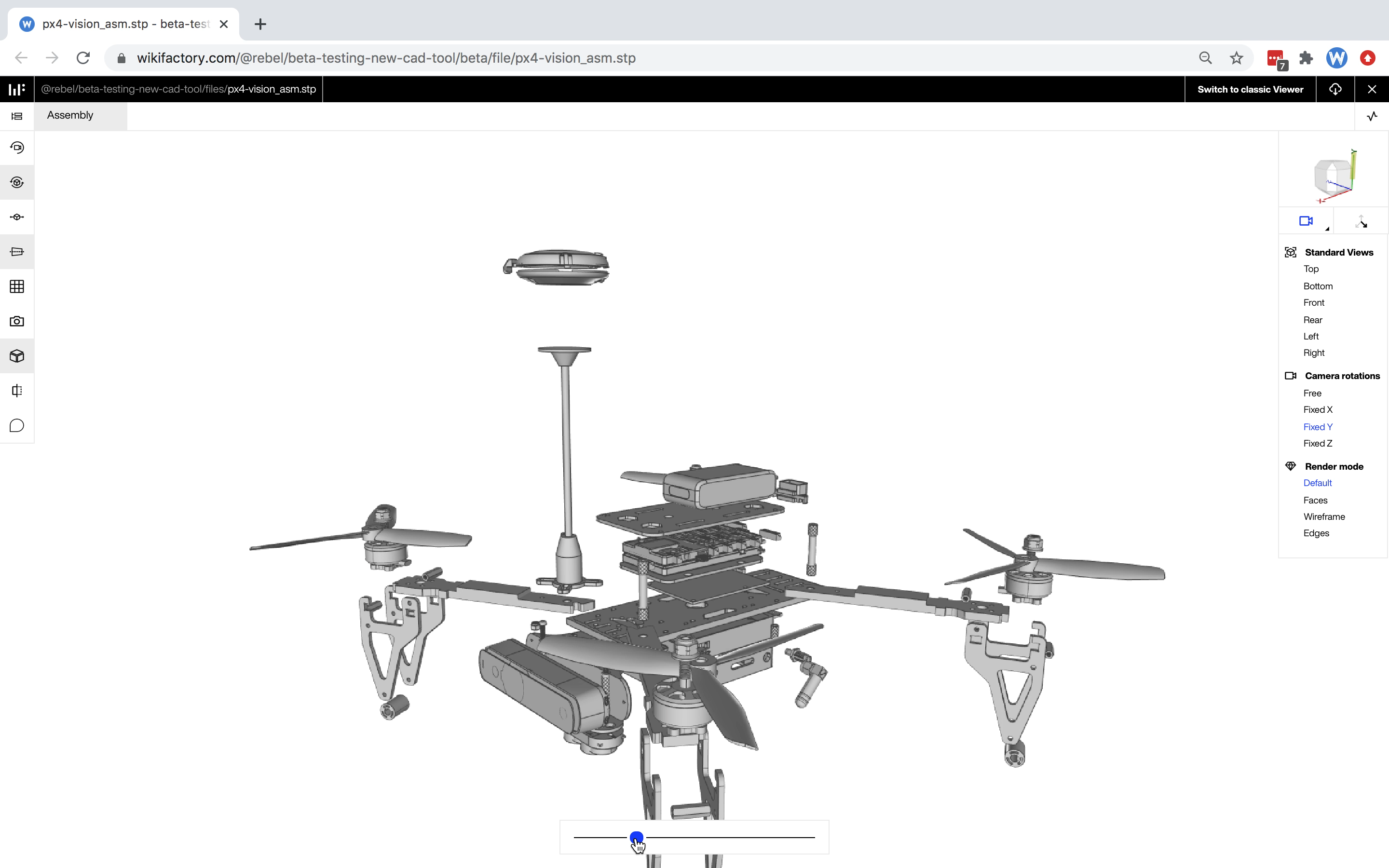

Wikifactory secures $3M funding and launches collaborative CAD tool

Wikifactory has raised $3 million in its latest funding round, which closed six months earlier than expected, to bring the total funding received by the start-up to $4.5 million. The seed funding came from impact investors across Europe and the U.S.

With the funding, Wikifactory plans to build a web-based quality-assured manufacturing marketplace to connect various “Big Industry” networks in one affordable and secure space. Since launching its Beta program in 2019, Wikifactory has seen more than 70,000 product developers use its platform to build robotics, electric vehicles and drones, agri-tech and energy appliances, lab equipment and 3D printers, smart furniture and biotech fashion materials, as well as medical supplies during the Covid-19 pandemic.

In addition to its funding announcement, the firm is also launching a new collaborative CAD tool to enable designers, engineers and manufacturers to collaborate remotely on virtually any CAD model from concept through to finished prototype. Featuring an in-built chat function, brand new annotation system, geometry explorer, and advanced visualization settings, the platform aims to open up accessibility and affordability of product lifecycle management (PLM) within the additive manufacturing industry.

“Today, as global supply chains are increasingly vulnerable, the need for a viable, alternative online infrastructure to prototype and produce products locally, to a high standard, and sustainably, has never been more relevant and necessary,” said Nicolai Pietersen, co-founder and executive chairman of Wikifactory.

He continued: “A new distributed model of global innovation for local production not only opens up access to the production industry and removes the barriers to start and scale a product business, leading to new socio-economic impetus, but also incubate a new economic model that demands less shipping, less costly inventories, and which might even change our consumption habits altogether.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed OneC1TY bandshell pavilion produced by Branch. Photo via Branch Technology.