A group of MIT researchers have devised a 3D printer addon that can be attached to any standard 3D printer and detect and then print on a different object on the print bed using a laser scanner and some custom software.

Starting with their Solidoodle 3D Printer, MIT students Claudio V. Di Leo, Louise E. van den Heuvel, and Sumant S. Raykar created an add on that uses a laser scanner and a webcam to detect the placement and orientation of an item left on the print bed. Then it can build a point cloud of the object that can then tell the 3D printer how and where to print on it. This means that you could print an object with two materials without needing two print heads or resume printing a job that was interrupted or failed.

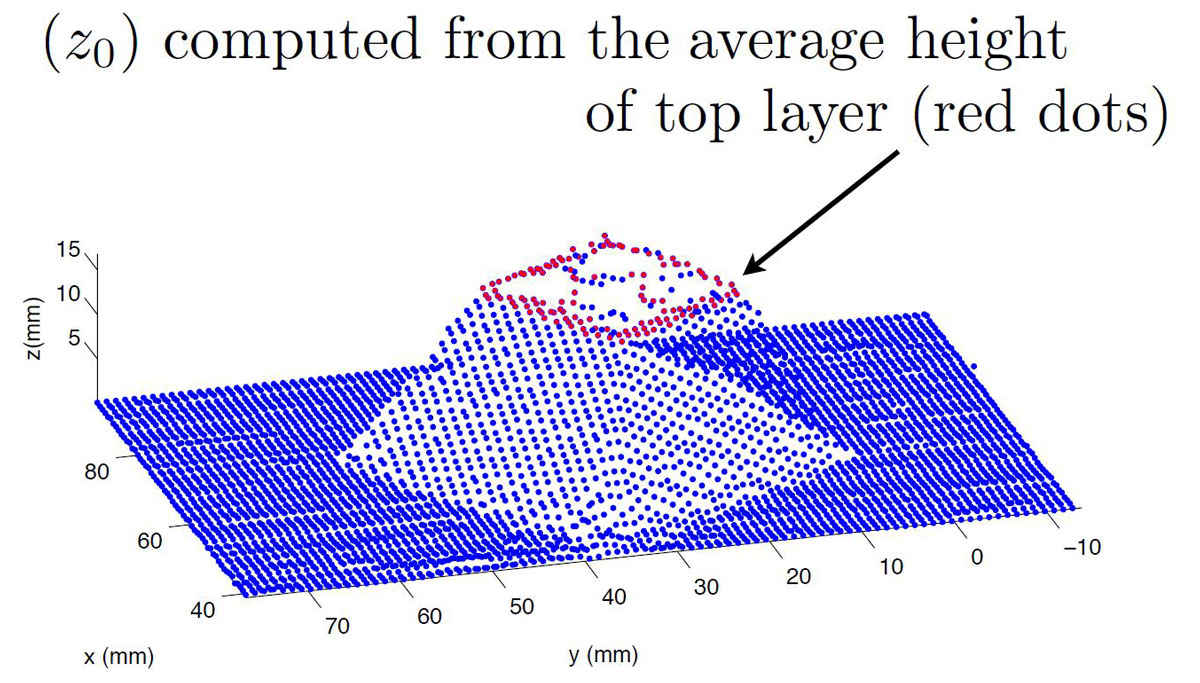

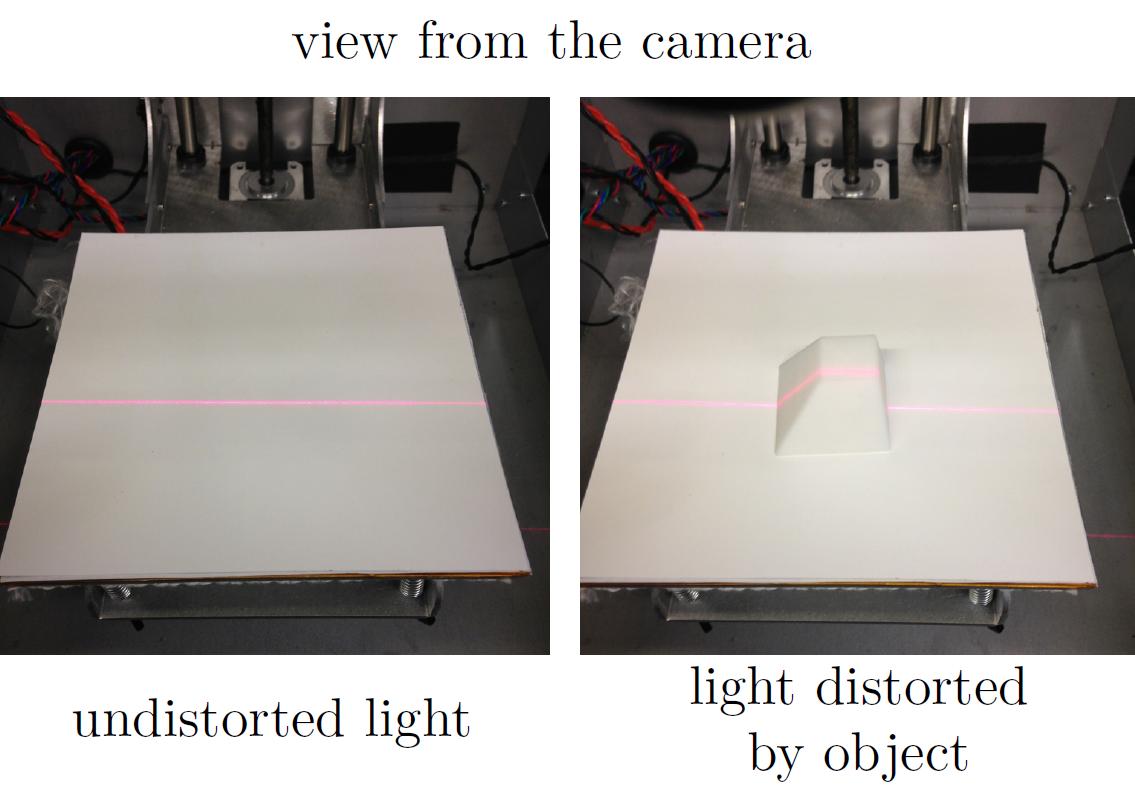

It works by attaching a laser scanner onto the 3D printer’s print head and projecting it onto the print bed. If the laser is distorted by the presence of an object on the bed it will inform the 3D printer. An attached camera will snap a picture and calculate the height of the object. Then the head will move to a new location and repeat the process. Once the laser has scanned the entire object all of the photos are analyzed and the point cloud reconstruction is completed the 3D printer is instructed where to start the new print.

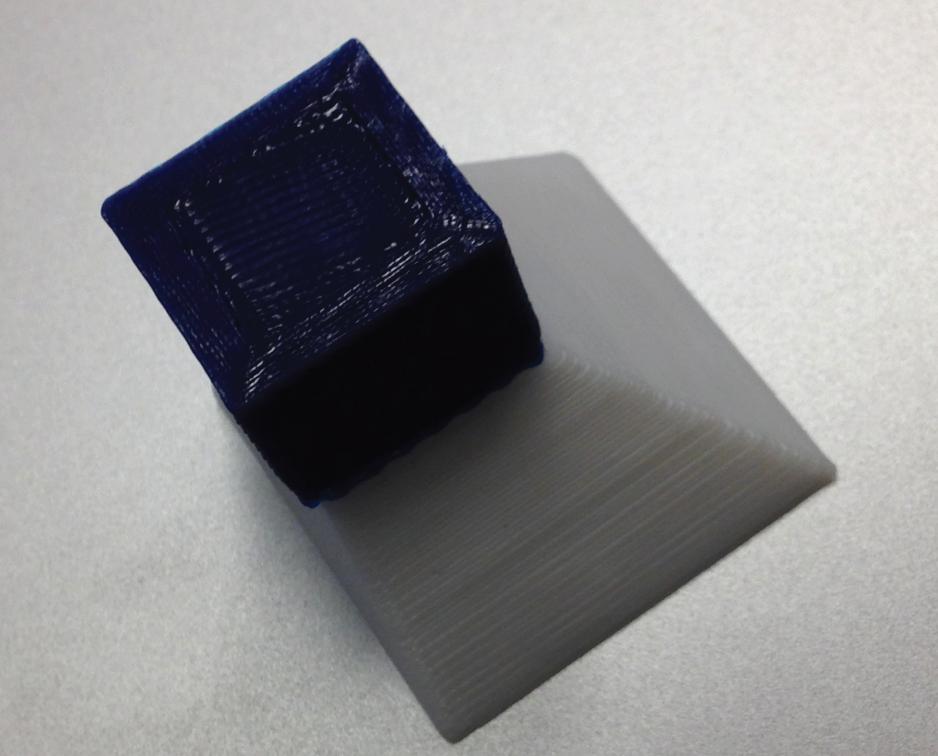

The researchers said that the trickiest part of the build is positioning the laser correctly and keeping it in place. It needs to remain perpendicular to the print bed because even a small tilt would render the scan data unusable and inaccurate. They solved the problem by 3D printing a plastic laser holder that attaches directly to the print head.

While the addon was built to work with the Solidoodle that MIT provided the researchers with, it can easily be applied to any 3D printer, and the materials will only set you back about $60. They used inexpensive over the counter equipment, so anyone can build this device using a simple $20 laser and a cheap $35 Logitech webcam. Here’s a video detailing how the printer add on works:

The students currently have no plans to continue this line of research but they are eventually going to compile it and make it open source — it will be available online for other people to work from. Beyond the obvious uses for this technology, they say that it can also be used to inspect an in process print job and detect if the print is failed before you waste filament and time. It is also possible to use it to level the print bed or home in on the z-coordinate.

This is an innovation that just makes sense, so let’s hope someone gets a hold of the research and builds it into their 3D printers. As 3D printing continues to become a wider adopted technology, many of the frustrations that veteran 3D printing enthusiasts deal with are simply going to need to be addressed. Wasted filament and interrupted prints are extremely frustrating and can often make you feel rather helpless. Being able to stop and restart a print, detect a failed print right away, or better yet, predict a potential failed print and correct it before it happens is just an obvious necessity for advancing 3D printing into more homes and small businesses.