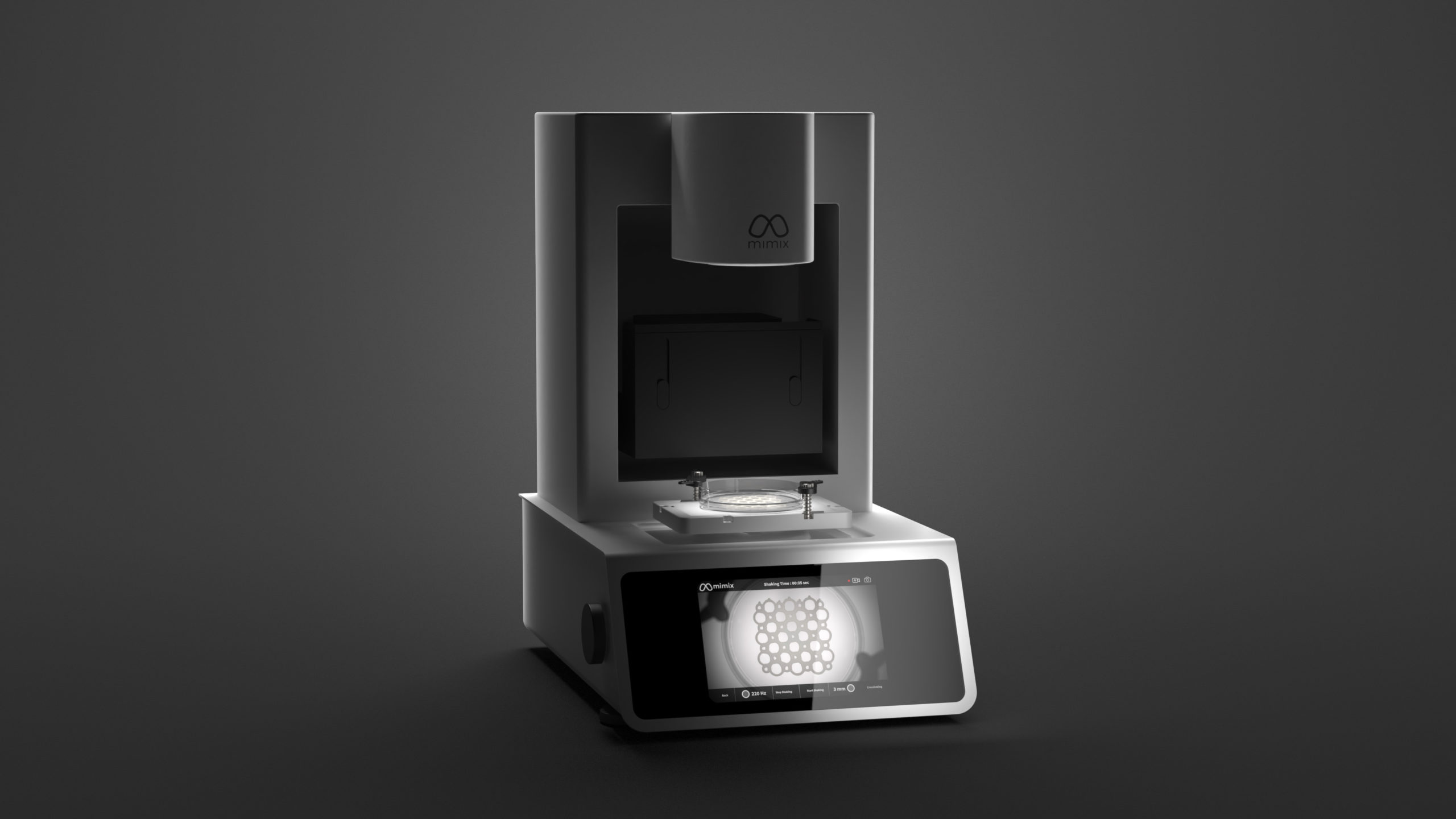

Biotechnology company mimiX Biotherapeutics has announced the launch of its first acoustic bioprinter – cymatiX.

Powered by the company’s proprietary Sound Induced Morphogenesis (SIM) technology, the machine reportedly enables users to “orchestrate life with sound”. It is intended as a fast and affordable method of fabricating multi-cellular tissue constructs, and is expected to overcome some of the technical limitations currently plaguing tissue engineering, regenerative medicine, and pharmaceutical research. The system is available to pre-order now, with deliveries set to begin in 2021.

Sound Induced Morphogenesis

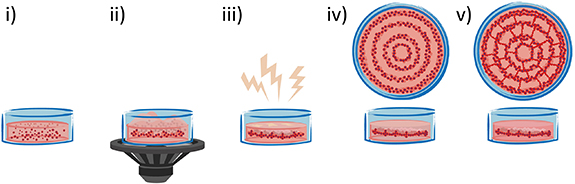

The SIM process is certainly a unique one. Unlike conventional extrusion-based bioprinters, cymatiX utilizes the phenomenon of resonance generated by sound waves to assemble biological particles into high-resolution patterns in a matter of seconds.

Cells, spheroids, and organoids are dispersed in a hydrogel precursor before being loaded into the SIM carrier in a petri dish. A vertical vibration is then emitted from a speaker below, assembling the cells in the dish into the desired pattern (the frequency of the sound can be tuned to modify the assembly pattern). Once the pattern is finalized, crosslinking within the hydrogel is initiated using either light, enzymes, or thermal energy, whereby the stimulus is dependent on the material being crosslinked. In a cyclic manner, multiple layers with different patterns can be stacked on top of each other to construct 3D structures.

The contactless process is very gentle, so as to not affect cell viability and metabolic activity. It also allows for organized cell assemblies with defined spatial resolutions and useful cell densities. As such, the platform could have great potential in R&D, via the accessible production of engineered tissue constructs and physiologically relevant in vitro models.

Tiziano Serra, Co-Founder and CSO of mimiX, said, “Instead of having dispersed cells with low density, researchers will be able to condense cells in a very fast and gentle process through the liquid movement of all the cells via a low-frequency vertical vibration applied at the bottom of the chamber. This dynamic cell condensation is one of the critical points for the regeneration of functional tissue.”

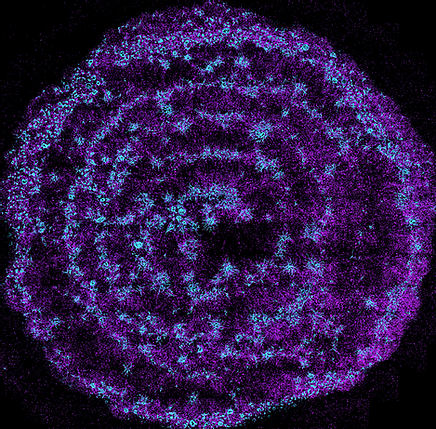

Bioprinting microvascular networks

The technology has already been featured in a number of scientific studies, including one titled ‘Sound-induced morphogenesis of multicellular systems for rapid orchestration of vascular networks’. In this proof of concept, despite starting off with a low cell density, the researchers were able to condense and self-pattern a set of endothelial cells and mesenchymal stem cells to create functional microvascular networks via SIM. The team ultimately concluded that SIM was viable for the application and should be explored further in the field of regenerative medicine and cell therapy.

Marc Thurner, Co-Founder and CEO of mimiX, added, “It’s all about cell condensation and patterning, these are the two secrets of life, and that is what we offer with our process, the capacity to condense and pattern. We are certain that cymatiX will offer much better performance than any other bioassembly process in the market today.”

Bioprinting is very much in its infancy, and is one of the more niche areas of additive manufacturing that still has a way to go. That being said, researchers from Harvard Medical School recently developed a novel algae-based bioink that, once bioprinted into soft tissue structures, demonstrates enhanced cell viability. The bioink comprises photosynthetic algae and human liver cells in a hydrogel matrix, and has been used to fabricate hexagonal structures featuring lifelike liver ‘lobules’.

Elsewhere, at Washington State University, researchers have previously developed a soy-infused bioprinted bone-like scaffold that’s capable of fighting off cancer cells. By integrating soy-based chemical compounds into 3D bioprinted scaffolds, specifically, the team showed that the approach could significantly reduce the volume of bone cancer cells in samples, while minimizing harmful inflammation.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the cymatiX acoustic bioprinter. Image via mimiX.