For years Greg Zumwalt wanted to know what’s the thing inside of a can of spray paint that makes the sound when shook. After finally one day opening an empty can he found a 10mm metal ball. Now for most people that would have been enough, but Greg went a little bit further playing with the idea what he could do with that metal ball. With the help a Replicator2 3D printer, Sketchup 8 and ReplicatorG software the Marblevator was born!

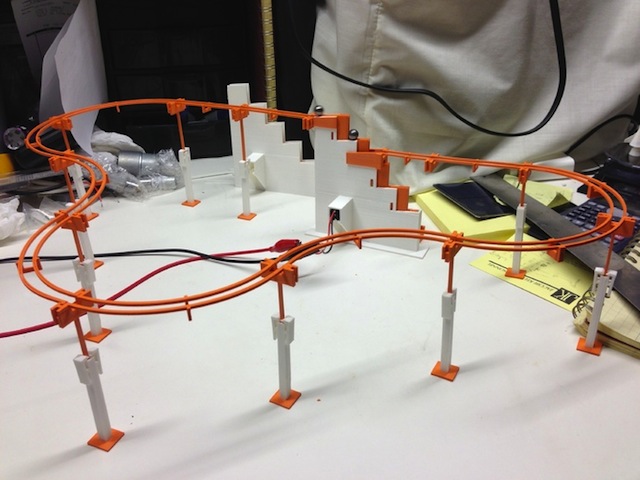

Marblevator is a marble ball track that features a cool elevator section. Various different track layouts can be assembled with snap / slide together construction.

The Marblevator files are downloadable at thingiverse. Greg provided instructions for those interested in trying to build their own:

The Marblevator requires the aforementioned metal spray paint ball (Or balls. Actually, I’ve heard 10mm marbles and beads are much more safely attainable, but I have not verified as such), a Replicator2, ReplicatorG software (free), PLA, 2 wires, a dc motor and a dc power supply. And if you don’t like my track segments, you’ll need Sketchup 8 (free) to modify the included “.skp” files to make your own.

Unless noted otherwise, the following ReplicatorG settings are used (using the GCode/Generate dialog):

Infill: 100%

Layer Height: .15mm

Shells : 1

Feedrate: 80

Travel Feedrate: 150

Print temperature: 230The various components were designed to print as fast as I could design them to print with minimal plastic (well, at least on a Replicator 2 using ReplicatorG with the recommended settings). Any further suggestions are welcomed.

Make sure your printer is tuned for .15mm printing.

1) Buy this motor: 6VDC 45 RPM Pinky Finger Sized Gear Motor 1″ Long x 15/32″ x 3/8″

from either amazon.com or directly from sciplus.com/p/MICROMOTOR_47952. In this application, the motor requires 10 to 20 ma to run which is suitable for a small power supply, battery and/or solar panel use.2) Buy a power source. I’ve used a “wall wart” variable power supply (3, 4.5, 6 vdc, the motor is rated to 6 vdc) and run mine at 3 or 4.5 vdc depending on the track design. I’ve also used a bench top linear variable power supply which comes in handy for track testing, but is not necessary. And I’ve also used 2 AA batteries, as well as a solar cell in bright sunlight (4.5 volt, 1.5 watt).

3) Print tressels. Print 10 each of each tressel piece (arm, base and clip). You’ll want more. Base should be printed at 20% infill to avoid warpage and save PLA. After printing, snap off the round skirt at the bottom of each tressel clip, and if required, carefully separate the jaws of the tressel clip using a modeling knife. The tressel clip should now act like a “clothes pin”. Pinch the handles, insert the tressel arm to the desired length, then let go of the handles. The base slides on the opposite end of the clip. It is a tight fit.

3) Print track segments. Each track segment has a female and male end. The female end also serves as the tressel attachment point. On the bottom of the female end is a small square hole which will be hidden when the tressel arm is attached. When you need to disassemble a track, remove the tressel arm, insert a small jewelers screw driver (or similar small object) into this hole, and press upward to separate the track segments. Following this procedure avoids having to pull the track segments apart and possibly separating (e.g. breaking, which of course can be fixed with cyanoacrylate glue if required, as if I’ve ever broken a track in haste, sigh) the track from the male track segment.

4) Print track start and track end. These components connect the track to the Marblevator. Track Start snaps onto step number 5 (the highest step) of the Marblevator. It has a male track connector extending down. Track End snaps onto one of the remaining 4 steps. It has a female track connector extending down. For short tracks, Track End is snapped onto step 4 (first step below the step 5). For large tracks, Track End is snapped onto step 1 (bottom step). Which step is used depends on how long the track is. If the track is designed too steep, you’ll lose your marbles (sorry, had to use that) in that they will jump the track. If the track is designed too shallow, your marbles stop.

5) Print arm.

6) Print staircase. This is a long print, but has been reliable for me as designed; keep your fingers crossed.

7) Print stair steps. Print at 20% infill to prevent warpage, save PLA and minimize the weight that the motor must lift.

8) Assemble the Marblevator (staircase, stair steps, motor and arm). Begin by soldering red and black wires to the motor + and – terminals. Slide motor into motor holder on staircase until the motor shaft just slightly enters into the inside of staircase (use the access hole on the opposite side of the motor holder to view motor shaft position). Orient stair steps such that the long narrow slot is vertical, then slide into staircase such that the slot surrounds the stair step guides inside staircase. Once installed, stair steps should move vertically with ease such that when you lift stair steps up then release, stair steps will easily fall to the bottom of staircase. Next, press motor further into the motor mount such that the shaft is half way through staircase. Press arm onto motor shaft via the access hole such that the motor shaft flat and arm flat mate, and the arm is inside the large rectangular hole in stair steps. Finally press motor all the way into the motor holder while positioning the arm on the shaft to allow it to be centered in staircase.

9) Assemble tressels (see picture).

10) Assemble and adjust track. This is your “free form” design. The prototype video shows an oblong track, the final design video shows a slightly more complex track. However, loop backs, circles, etc. are possible. When your track is complete, carefully adjust the tressel heights for a smooth descent from track start to track end. “Tuning” your track is crucial. For example, you may start with a rapid descent and end by slowing the descent via increasing the tressel height at the end of your track before returning to the Marblevator. Gravity is relatively constant (for the time being), so experiment with tressel heights to obtain the best combination between track slope and track length. The tracks I’ve assembled run for days without a marble jumping the track.

11) Connect motor to power supply. This is also your “free form” design. The video shows mine connected to a variable dc bench power supply with alligator clips. Your choice.

12) Marblevate. Make new tracks. Show off your track building skills and please post your tracks!

13) Questions? Send a comment, I’ll try my best to respond. Have fun. Makes a great gift for your aspiring engineer.