Stratasys subsidiary MakerBot and 3D printer manufacturer Ultimaker have announced a merger that will see the creation of a new desktop 3D printing company.

Backed by existing investors NPM Capital and Stratasys with a planned $62.4 million investment, the new company will be co-led by MakerBot CEO Nadav Goshen and Ultimaker CEO Jürgen von Hollen, with Goshen managing operations and von Hollen managing the commercial functions.

The deal is expected to close within the next few weeks, upon which the name of the new company will be announced. The two firms believe that by combining their respective expertise, they will be able to accelerate the adoption of additive manufacturing and expand innovation within the desktop 3D printing sector.

Discussing the merger on a press call, von Hollen said that, among other advantages, the move will enable the firms to get closer to their end customers.

“The new company will be able to invest in providing real value to our customers,” he said. “We want to move towards customer-oriented solutions that include ease of use and flexibility, and a truly integrated workflow is one of the key aspects.

“Secondly, if you look at the market and global reach we have a unique opportunity to get closer to our customers and our partners in order to grow the market.”

Details of the merger

Once the merger is finalized, Stratasys will own 45.6 percent of the new entity while NPM Capital will own the remaining 54.4 percent. As a result of the new company’s formation, MakerBot will be spun off from Stratasys, and although it will retain commercial and IP ties with the firm, it will be operationally independent.

The firms will transition over their existing product portfolios into the new company, and will then begin adding to this with new and improved desktop 3D printing capabilities regarding hardware and software.

The new company will maintain headquarters in both The Netherlands and New York in the US, and will expand its global footprint with sales and operations in the Americas, EMEA, and APAC markets.

The $62.5 million investment will be funneled into broadening and accelerating the development of the new company’s portfolio of hardware and software products, and will aid the company’s expansion into new markets.

Over the next few months, MakerBot and Ultimaker will begin integrating their teams and their respective businesses into one entity. Once this is complete, we will have a clearer idea of how the company will be structured.

A complementary match

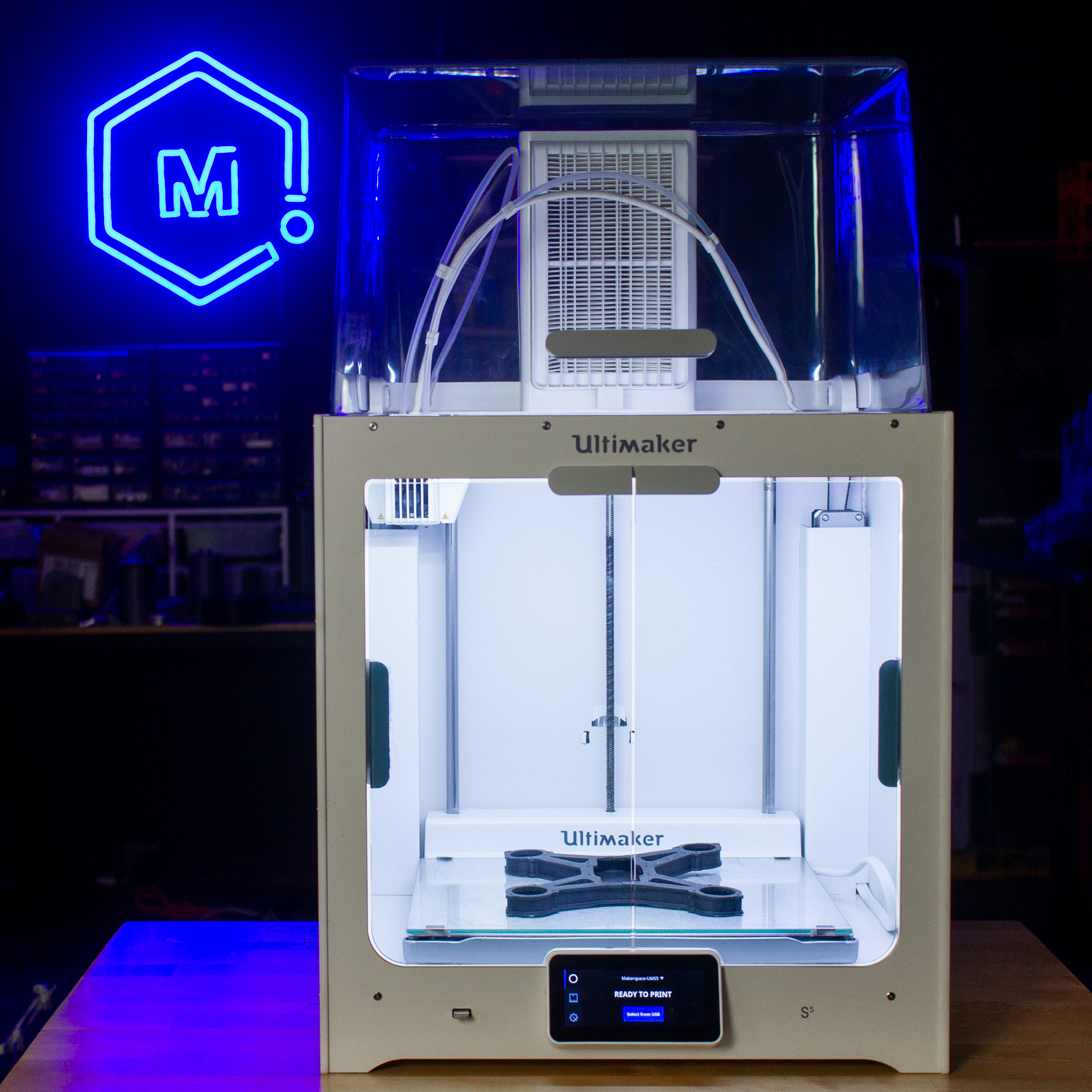

Since its founding in 2011, Ultimaker has built up a range of open-material FFF 3D printers designed to accelerate flexible and sustainable production. To this end, the firm has invested heavily in its own software portfolio, including its Academy, Digital Factory, and Cura offerings.

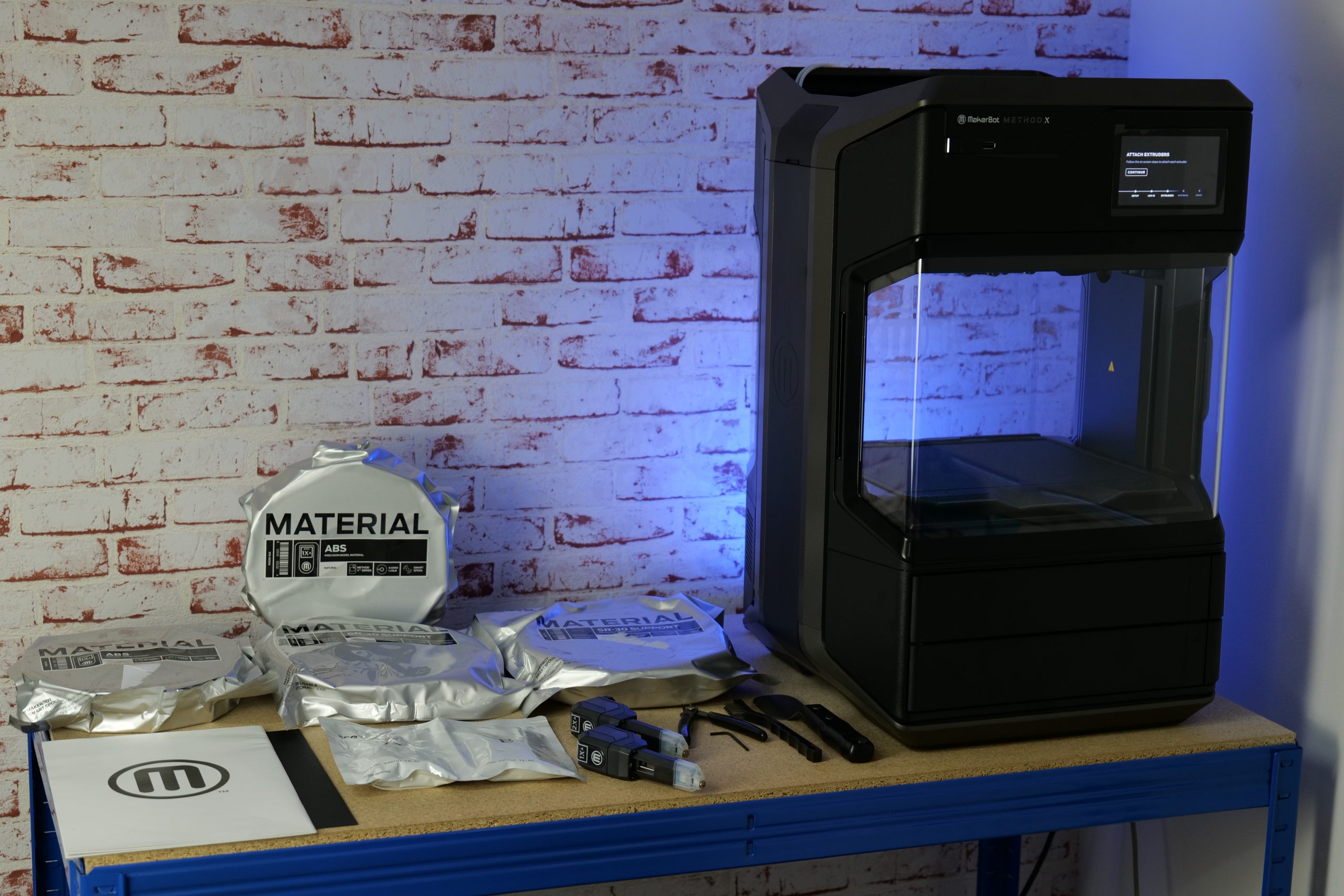

MakerBot, meanwhile, has made a name for itself in the professional-grade 3D printing space with its suite of extrusion-based machines. The firm’s flagship METHOD 3D printer range comprises the older METHOD, newer METHOD X, and higher-performance METHOD X Carbon Fiber systems.

Both von Hollen and Goshen believe the two businesses complement each other in many aspects, which was a key driver of the merge.

“We see that we have a shared vision and it is to make desktop 3D printing accessible but also professional,” explained Goshen. “I think we can achieve that by combining together, and this is all about growth. We are going to grow the market and step up from current technologies that are limiting democratization.”

During the call, von Hollen discussed how the desktop 3D printing market has experienced elements of confusion and customer fragmentation in recent years. According to him, combining the two companies will allow for the scale and the funding to invest in providing something that is engineering-grade and easy to use, while remaining affordable.

“I think this is where the markets have stopped evolving, because of the fragmentation and because of market size” he said. “So the need to scale and the need to invest has come from the market, which are the drivers behind this merger.”

When asked what an ‘UltiBot’ could potentially look like, the pair remained tight-lipped on the details and instead focused on how the firms’ two technologies will complement each other.

“When we look at MakerBot from the Ultimaker perspective, we see a much more commercial-oriented business that is very focused on the direct channel and close to the customer base,” von Hollen continued. “Whereas we are pretty far away from our end users, and over the past year we have been trying to get closer.

“So, when we started the first discussions of this potential merger, it quickly became clear how similar the DNA of our companies was in terms of culture and vision.”

Ultimaker’s application engineering expertise will also enable the new entity to address the professional and ‘light industrial’ sector under one portfolio with global coverage. Goshen echoed von Hollen’s thoughts, explaining that being part of a publicly-traded company such as Stratasys can impose limits on networks, funding, and the ability to scale.

“We can take all of the volume that is out there in the additive manufacturing community and we want to invest more,” he said. “Together with our teams and the funding, I think we are really set to take it to the next level, and we are excited about that.”

Achieving next-level desktop 3D printing

The merged company will look to provide a comprehensive ‘ecosystem’ of hardware, software and materials for the desktop 3D printing market to an expanded global customer base. According to von Hollen, the real potential of the market has not yet been realized, and this is what the new company will address with its combined portfolio.

“As we start moving upwards into the light industrial space, it is here where we see the opportunities that today are not being met,” he explained. “There’s an opportunity for us with those solutions that when combined, developed and delivered, will allow us to enter that market.”

Goshen agreed, saying: “We can develop a strong, robust, repeatable printer in the $15-$20,000 price range that can do much more than what we can today. We want to be very specific and focused in the way we go to market and how we position our products, and that will be our mission over the next few weeks and months.”

Once the companies have merged, they will also continue to target the education market with a “complete solution” in order to spearhead the adoption of 3D printing within educational settings. While both companies are active in the education field – Ultimaker more within higher educational settings like universities – MakerBot’s extensive reach within the classroom will aid the newly formed company in this endeavor.

“This merger marks an important milestone for Ultimaker and MakerBot,” said von Hollen. “Innovation and growth are both critical to bringing desktop 3D printing from a specialty technology into mainstream business adoption. The new company will leverage and expand its combined global footprint with sales and operations in the Americas, EMEA, and APAC.”

Goshen added: “Technological innovation is paramount in growing the availability of easy-to-use professional 3D printing solutions.

“By combining our teams and leveraging the additional funding, we can accelerate the development of advanced solutions to provide our customers with a broad portfolio of hardware and software solutions.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows the MakerBot METHOD X. Photo by 3D Printing Industry.