With 3D printing, you can print objects with almost any interior geometry you can imagine. Typically, this has been taken advantage of to reduce waste through the printing of semi-hollow rather than completely solid shapes. Researchers at the Interactive Geometry Lab, of the scientific and technical university ETF Zurich, have found a new way to use this feature of additive manufacturing to create balance in any printed item.

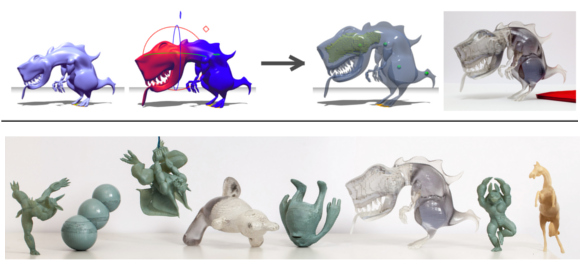

Make it Stand is an application, yet to be made available to the public, that allows users to modify any 3D model in such a way that, when printed, its center of gravity will ensure that it balances perfectly. In the Make it Stand optimizer, users indicate the points of balance on an object, where they intend its base to be, and then add a few handles. The Make it Stand algorithm then hollows out portions the object and manipulates its exterior, based on where the handles have been placed, so as to redistribute the weight in the appropriate way to, well, make it stand. The deformation of the model’s exterior is meant to be minimal, so as to preserve the designer’s original concept. Here’s how the program’s developers describe it in their official publication:

Our approach combines stability objectives with shape preservation measures in order to respect the user’s original design, whilst making it feasible without the need for aids such as an oversized base or the addition of stilts. We introduced a novel algorithm that leverages the use of interior voids to manipulate mass distribution without affecting the exterior appearance of the model. We alternate between interior carving and shape deformation to arrive at a final stable result. We have demonstrated effectiveness with numerous results including character models and everyday objects, many requiring particularly delicate balance conditions to stand in equilibrium. Further, we extended our technique to objects that stand on multiple bases.

So, say you want to print your Yoda statue so that it will stand upside down. Well, with Make it Stand, you can hollow out a portion of your model, while adding an interior fill to another portion of your model. and stretch the Yoda head so that its mass is distributed to the appropriate areas to keep it upright. Make sense? If not, watch the video below:

The team, made up of Interactive Geometry Lab and INRIA‘s Romain Prévost, Emily Whiting, Sylvain Lefebvre, and Olga Sorkine-Hornung, first demonstrated their work at the ACM SIGGRAPH 2013 convention in Anaheim, California. The researchers indicate that they can extrapolate their algorithm to work with multiple materials, as well, saying:

Our focus has been on printing single material models. It would be possible to generalize our method to several materials. Varying densities in the mass distribution would further reduce the deformation of the surfaces. Due to limitations in current printing technologies we keep this for future work.