Tomorrow at Inside 3D Printing Santa Clara, Aleph Objects, makers of the LulzBot line of 3D printers, will debut a prototype model of their new desktop 3D printer. Made to be a small, but powerful, addition to their series – which includes the larger TAZ 4 3D printer and its kit companion, the KITTAZ – the fully-assembled LulzBot Mini will go on sale in December of this year for $1,350.

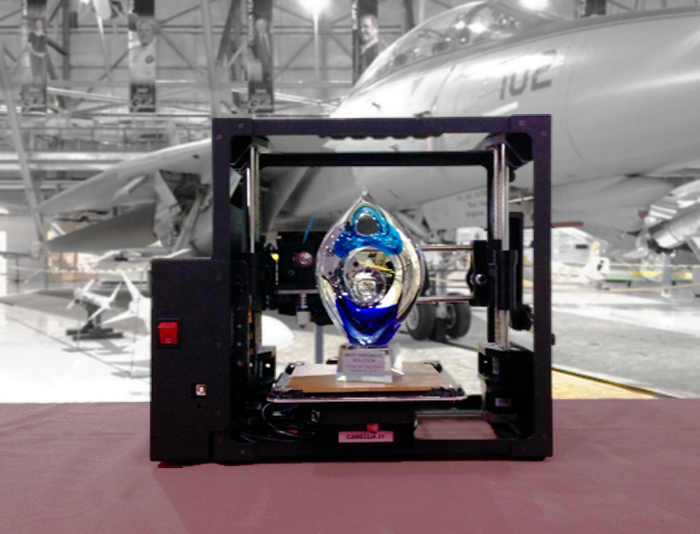

The LulzBot Mini has been in development for quite some time, making an appearance at World Maker Faire New York this year as a second generation prototype with the code name Begonia. The printer then made its next appearance with some improvements and a new code name, Camellia, at the Denver Biz Tech Expo, where it was voted as the Best Hardware Solution. Finally, the machine was polished off with the code name Daffodil, now being presented at Inside 3D Printing.

Daffodil, soon to be the LulzBot Mini when it launches in December, has a build volume of 6″x 6”x 6”, about half the size of the TAZ 4, but it packs a big punch. This new machine has an all metal hot end, made in partnership with RepRap Discount and capable of printing at temperatures up to 300°C (572°F), combines with an advanced heated bed to give users the ability to print with materials like Nylon, Tritan, T-Glase, Polycarbonate, and imitation wood, bronze, and stone filaments. The Mini also has an automated nozzle cleaning sequence and auto-bed leveling, created with the help of SparkFun Electronics. All of this is powered by a Mini RAMBo, developed with Ultimachine, and is housed in a powder coated aluminum frame.

The LulzBot Mini will continue Aleph Objects’ philosophy of fully open source hardware and free software so that you can source the parts to create the machine and build it yourself, following the Open Hardware Assembly Instructions here (the actual instructions the company’s manufacturing facility in Loveland, Co. uses to build the machine) and the GitHub files here. Or you can examine their plans and use their software to rig your current 3D printer to feature auto-bed leveling, or “auto-bed compensation” as Aleph Objects likes to call it. If you’re in Santa Clara for Inside 3D Printing, be sure to check it out in person. Otherwise, wait until December and buy one for yourself!