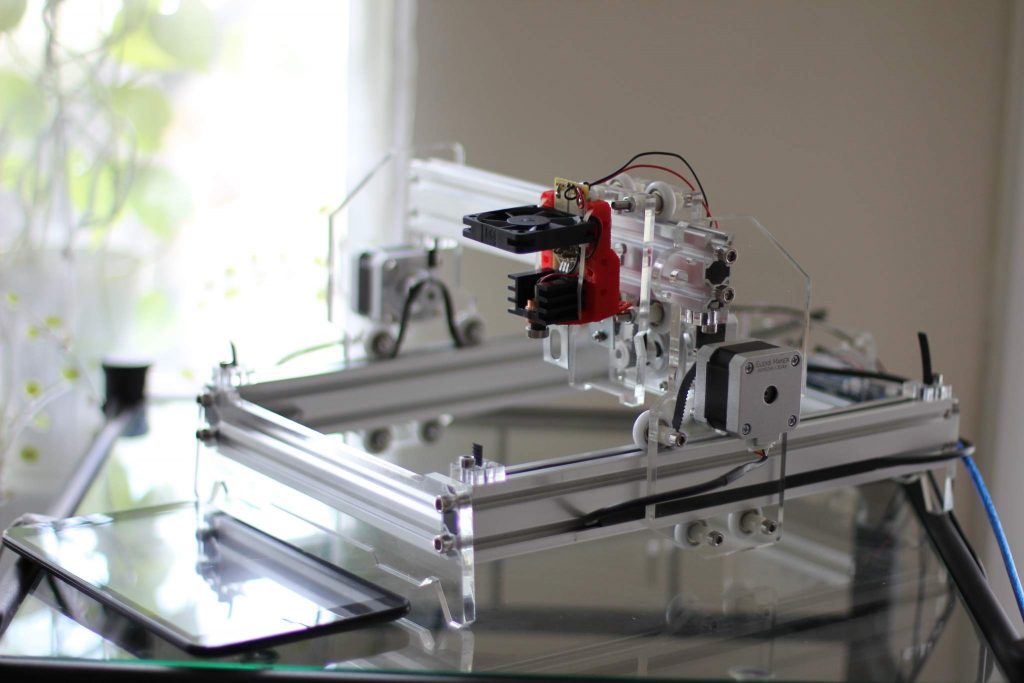

Did you know that by simply adding a Diode Laser Endurance L-cheapo, you can turn your 3D printer into a desktop factory that will give you so many more options?

You can cut, mill and engrave your products with no additional software. This simple laser can even help you with basic welding, brazing and precision soldering.

From science fiction to everyday life

Not so long ago, lasers were the work of science fiction. Now we have them everywhere. That means they are getting cheaper, more compact and more advanced all the time.

Robots Everywhere in the US developed this system that is on sale in Europe through Endurance. Available as either a 2.1 or 3.5W system, this laser is designed to work as an engraver with most 3D printers. It can also act as a milling tool and a laser cutter. In fact, it is a spectacularly diverse tool that can operate with existing software and you don’t even need a separate power supply. When you’re done, you can remove it in a matter of minutes as well.

Cutting can be a better and quicker option for you that printing out each separate part, so by using your existing software like Slic3r and Skeinforge, you can turn your 3D printer into a desktop workbench and flip between the tools to speed up your workflow.

Cut a variety of materials

The laser can cut paper, plastic and wood up to 3/16ths of an inch. It can also handle other materials including foam, leather and felt. It can also engrave ceramic and metals. So if you want to cut a precise template or any manner of other things, then this could be a fast answer.

Most home hobbyists have considered a laser cutter at some point, it’s a cool piece of kit that can do a number of different things. The cost of entry, though, is high. L-cheapo brings the price point down from thousands to just $195 for the 2.1W version and it effectively replaces expensive CO2 engravers and CNC machines.

It’s a product that can bring laser cutting and engraving in to schools, hacker spaces and home workshops. It is also an ideal upgrade for a 3D printer. Once people are comfortable printing 3D models, they inevitably run into limitation after limitation and this simple laser gives you so many more options when it comes to your creations.

Save time and get a better finish

Printing a large, simple shape from PLA is time consuming and sometimes it simply isn’t the best way. But if all you have is a 3D printer, then that is your only option. A laser cutter could take a fraction of the time, provide a cleaner finish and a stronger end product. There really isn’t a downside.

Simple welds, brazing and soldering can totally interrupt your workflow, too, as you need to set up a separate workspace and move between the two. Adding an L-cheapo laser to your arsenal means you can turn your 3D printer into all of these tools in minutes. It’s safer than doing these jobs by hand, it takes less time and you get a more precise finish.

The laser can also turn a simple 3D printer into a serious production tool that can produce printed circuit boards, combinations of metals and plastics and all manner of creative options that go beyond 3D printing.

So if you’re looking to take your hobby shop to the next level. If you want to make progress, not just models, and if you want to challenge yourself with different production methods, then think about adding an L-cheapo laser to your 3D printer. It will give you a whole world of opportunities.

Tutorial how prepare Gcode to make laser engraving using inkscape

For more informations, visit EnduranceRobots.com & EnduranceLasers.com