Chinese tire manufacturer Linglong Tire is developing the country’s first 3D printed tire along with Beijing University of Chemical Technology (BUCT).

The Chinese company has approached the additive manufacturing technique in a bid to provide a greener solution for the tire industry. Prior to this, Linglong has explored the possibilities of producing tires using dandelions and graphene as it strives for green, energy saving, high performance tire materials.

Low rolling resistance

The Linglong 3D printed tire is fabricated out of thermoplastic polyurethane (TPU) and Linglong believes this material has lower rolling resistance and heat resistance compared to conventional rubber tires.

By reducing the rolling resistance, Linglong will be able to provide a more fuel efficient tire. According to the U.S Department of Energy, as much as 11% of a conventional car’s fuel is used on overcoming rolling resistance. This percentage gets even higher when considering heavier vehicles.

Additionally, the fabrication method also promises lower costs than the traditional tire making process which involves molds.

Moldless tires

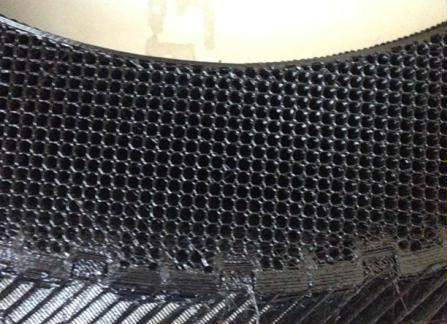

Linglong, together with BUCT, produced the tire using an FDM 3D printer. The tire’s internal hexagonal geometry removes the need for air in a similar way to French tire company Michelin’s concept tire. Linglong explains the alternative manufacturing technique still ensures safety, endurance and environmental protection as the tires can be easily recycled.

The Chinese company is certainly not the first tire company to explore the use of 3D printing, as mentioned with Michelin. However other companies have only showcased concept tires with the technology. American tire manufacturer Goodyear also proposed a 3D printed concept tire last year – the Eagle 360. Not only was this design 3D printed, but the tire was also completely spherical.

It seems that Linglong’s aspirations for 3D printed tires are notably more grounded. The project is combining academic researchers to genuinely explore the feasibility of 3D printed tires. While French tire manufacturer Michelin is currently using its relationship with Fives Addup Solutions to create metal 3D printed tire molds, Linglong aims to continue development of its moldless 3D printed tires to ensure similar high quality and performance.

For all the latest automotive 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows testing of the 3D printed tire. Image via Linglong Tire.