Multi award winning 3D printer provider Markforged has launched a new AI technology. Named Blacksmith, this cloud platform from the Massachusetts-based engineering firm goes beyond the company’s typical remit into a solution promising to improve the dependability of all manufacturing technologies.

Ahead of Blacksmith’s official launch at RAPID + TCT 2019 in Detroit, 3D Printing Industry spoke with Jon Reilly, VP of Product at Markforged, and Greg Mark, the company’s Founder and CEO.

“We’re a 3D printing company, but the reality is we’re software,” explains Mark. “Now we are making probably one of the biggest announcements we’ve ever made, which is a way to reinvent manufacturing that we’re calling adaptive manufacturing.”

Put simply, adaptive manufacturing in Blacksmith is achieved by connecting three parts of the fabrication process: scanning/inspection, hardware and software. By collecting data from each of these steps, the platform learns how to improve the way a part is manufactured.

“We won’t stop at 3D printing,” Reilly adds, “We’re going to extend it to all sorts of manufacturing machines.”

A sight for machines

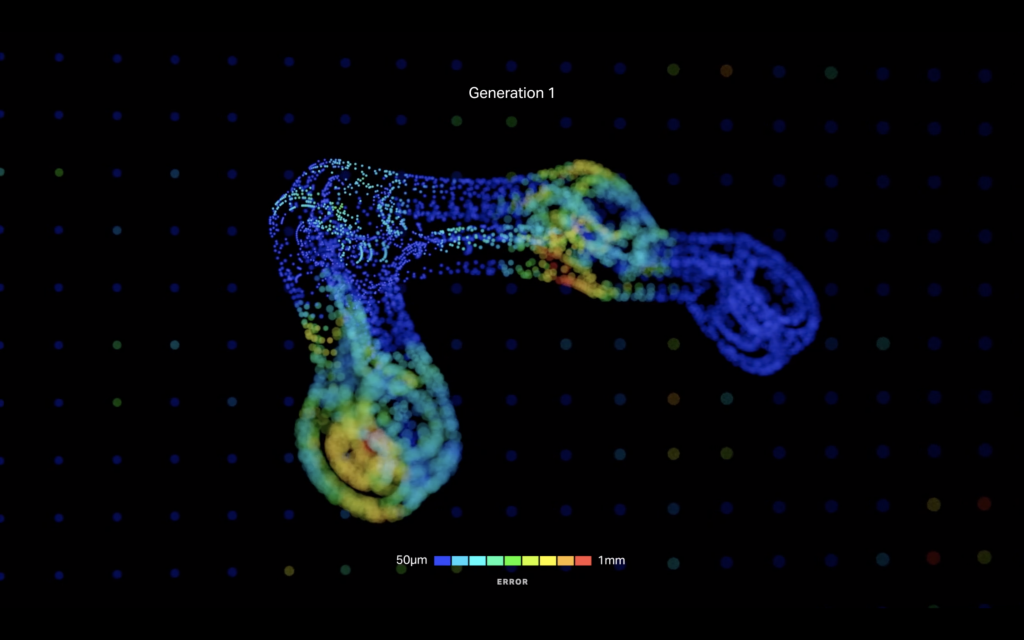

The way Blacksmith works is that a part is scanned each time it is 3D printed. The point cloud data from this scan, as well as process parameters and some CAD information, is automatically fed back to Blacksmith. The technology then compares all the data to determine how the outcome can be made closer to the intended CAD file.

Without such a process, machines are blind to the objects they are making. Rather than carrying any specifics about a part though, the platform is more interested in the fundamentals of a design, e.g. the optimal conditions for creating bridges in a 3D printed part, or how to create features of a certain size. In this sense Blacksmith’s intelligence, according to Mark, can be likened to the way Tesla “teaches” its cars to drive.

“They don’t care how you or I drive visually, they’re just learning how to drive,” he explains. “AI is learning how to drive. AI is learning how manufacturing works. How sintering works. How CNC machining works. How 3D printing works.”

“By integrating all that information, we allow it to understand more about manufacturing than any human possibly could.”

The more data Blacksmith is given, the tighter the tolerances it will get when producing parts. In 3D printing, Markforged is currently producing tolerances comparable to casting. The pursuit of the Blacksmith platform is to get as close to the digital CAD file as possible.

Blacksmith availability

According to Markforged, Blacksmith is the first technology of its kind in the industry. At this stage, it has only been tested internally at the company. However, the few external partners the team have shared the idea with have expressed interest in the tool.

At RAPID + TCT this week the team are showing their first demo of Blacksmith to the public. A pilot trial of the platform for partners is scheduled to roll out in Q3 2019.

On full availability of the technology, there will also be a cost introduced for customers seeking its integration. “There will be a cost to run Blacksmith,” Mark adds, “But production will be dramatically more cost efficient that not having it and making incorrect parts.”

Find the demo of Markforged’s Blacksmith AI technology, and 3D printers including the Metal X and Mark Two at booth #207.

For to-the-minute coverage of RAPID + TCT and all the latest 3D printing events, follow 3D Printing Industry on Twitter and subscribe to our daily newsletter.

Vote for your Innovation of the Year in the 2019 3D Printing Industry Awards.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Markforged Blacksmith. Image via Markforged.