The UK’s innovation agency are running a competition that will award £4.5 million ($5.82m) to, “projects that stimulate innovation in additive manufacturing, also known as 3D printing.” I spoke with the lead technologist for high value manufacturing at Innovate UK, Robin Wilson, to learn more. In this interview he explains how to access funding for 3D printing projects, what sectors should expect to see the biggest revenue in the next years, where there are opportunities for businesses and where are the 3D printing job opportunities for individuals.

“We think AM could be worth £1 billion ($1.29b) per year incremental business for the UK by 2020,” he tells me. Wilson is well suited to this role having worked with additive manufacturing for more than 20 years and is no stranger to innovation. During his time at automotive maker Land-Rover he worked on, “a fore-runner of Industry 4.0.” He explains, “we CAD modeled the whole car and how it would be put together in real time to not only get the product design right but the manufacturing environment could also be developed in parallel.” This was more than 2 decades before the current interest around intelligent factories.

Agency of Innovation

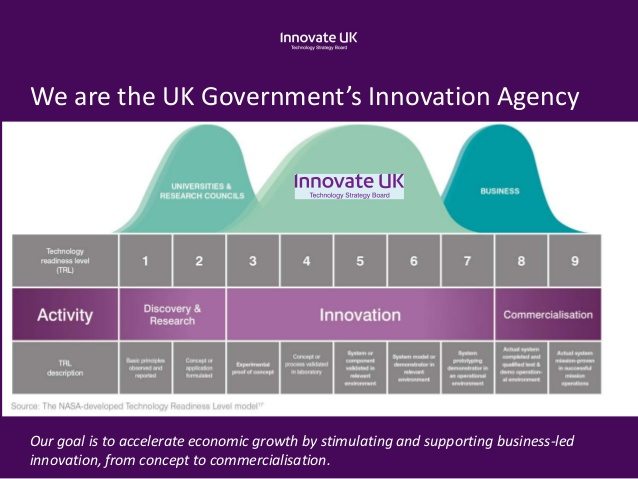

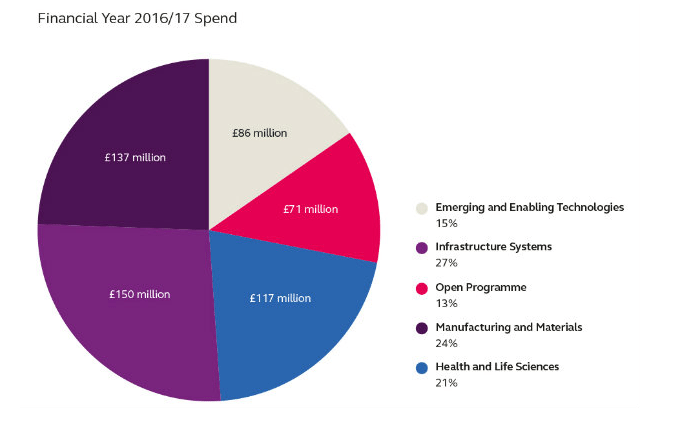

Innovate UK operates at arms length from the British government and works with companies, and consortiums, to enable and support innovation. The agency provides funding for projects in 4 sectors, health and life sciences, infrastructure systems, emerging and enabling technology and finally manufacturing and materials. To date 7,600 organizations have been supported resulting in 55,000 new jobs and over £13 billion ($16.8b) added to the economy.

Wilson explains that the level of funding depends upon the nature of the organization, “We typically fund projects at a 50% rate for a large company, up to 70% for a small company and 100% for an academic organization.” He continues, “Our strategy is to turn a technology that has come out the prototyping world and turn it into a proper production method.” This means a focus on innovation. “Most AM and 3D printing platforms are perfectly capable of making prototype parts and parts for manufacturing tooling equipment. There’s no point in putting public money behind that,” says Wilson. “When you’re in the innovation world you need to be planning for 4 or 5 years time in order to compete,” he adds.

The development of high value manufacturing Catapults is another aspect of the agency’s plan. These serve as research and development facilities that span the gap between early stage research typically conducted by academic institutions and the later work necessary to commercialize it. An example is the National Composites Center (NCC), a partnership between aerospace companies including GKN and Airbus and the University of Bristol. Located in north Bristol, work at the NCC includes automating manufacture of wings for the next generation of commercial airliners.

“Aerospace is investing the most (in AM/3DP) in terms of sectors at the moment. That’s a worldwide wide phenomenon not just in the UK,” explains Wilson. Innovate UK focuses on, “Areas of business where there is significant high value to be had in future years. Such as aerospace, medical, motorsports, the energy sector and some areas of consumer goods.” Additive manufacturing in these areas, “can really optimize the design to give higher levels of performance. Companies can gain a competitive advantage by producing something in a way that makes their product or service better than the competition.”

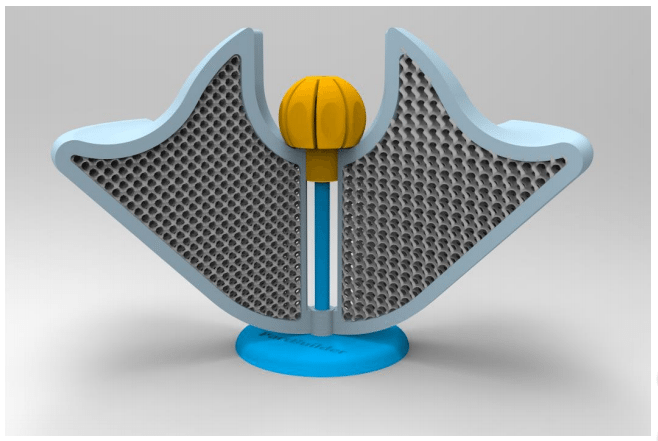

There are other advantages to additive manufacturing. “Bio active glass is an example where with AM you can give a material properties that you couldn’t with conventional processes,” says Wilson. Bio active glass is used in medical implants and AM processes can increase the rate of success for surgical procedures by mitigating rejection issues.

The agency first approached additive manufacturing in 2012 and the following year launched “a funding call of £8.5 million GBP ($11m) leveraging a similar level of matched funding investment from industry.” This resulted in approximately £15 million pounds ($19.4m) of investment across 18 projects. Wilson says, “most of them have now completed and the rest will be completed later this year.” Innovate UK will release case studies of the completed projects later in the year.

One of the first projects to completed was called PRECIOUS and focused on jewellery. Lionel T. Dean is an artist with more than a decade of experience using 3D printing as part of his art and design practice. He was involved with the PRECIOUS project and talks about his work in the video below.

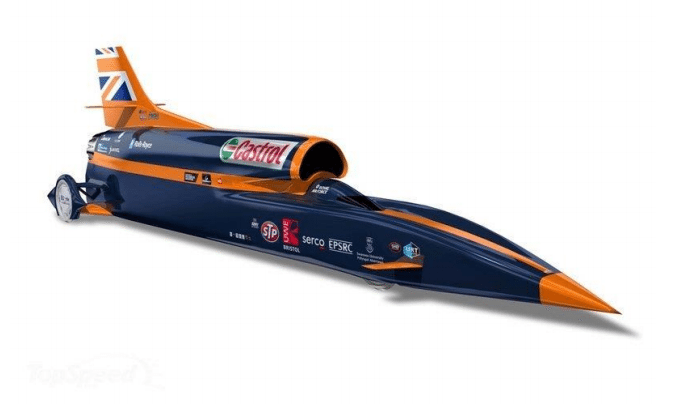

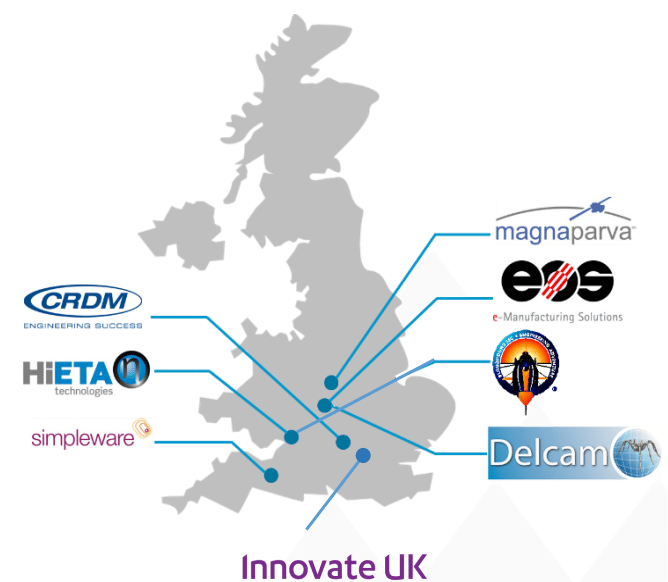

Another of the 18 projects funded by Innovate UK and recently completed relates to the industrial use of additive manufacturing. The LIGHT project uses the design freedom of 3D printing to create lightweight metal components. Members of the LIGHT consortium include the Bloodhound SSC, a supersonic car that will travel at 1,000 mph, and Magna Prava, designed to bring back soil samples from Mars.

The qualification and certification of materials and processes and the related development of standards is seen as a critical to the industrialization of additive manufacturing. Innovate UK does not use funding for this area but is keen to encourage activity. Wilson says, “Manufacturing is a complex process.” He continues, “Because AM & 3DP have come from the process world where you’re making one offs and two offs, the discipline that you see in a normal production process of machining, forging, injection molding, those are not really embedded yet.”

Industrialization and 3D printing within Industry 4.0

Continuing with the theme of industrialization I ask about other barriers to wider adoption. “Cost and time are always seen as inhibitors to applications,” Wilson tells me. But he believes there is a bigger issue that is not currently adequately addressed. “What is not getting enough attention is post-production finishing.” He continues, “Most manufacturers would have you believe that you just press the print button and out comes your finished component from the machine. In practice, a degree of finishing is needed to take off surface roughness, or to take powder out. For some applications it requires quite extensive processes such as heat treatment or hot isostatic pressing.” He adds, “These can be very manually intensive processes and we’re seeing evidence that those factors can contribute up to 50% of the overall production cost.”

With the agency’s current funding call they hope to see projects that will address post-production finishing. It is an area that will need to be improved if 3D printing is to become a core part of manufacturing in the time of Industry 4.0. Wilson says that, “There’s a huge opportunity for quality improvement and process consistency by applying some of the disciplines around Industry 4.0 to additive manufacturing.” Part of this is linked to the increased ability to handle large amounts of data generated by factories, a task that was not possible a decade ago. This brings an opportunity for manufacturers, “exploring what extra value can they bring to the business. Looking out towards the customer or processing back upstream in the supply chain or looking out at various quality control methods.”

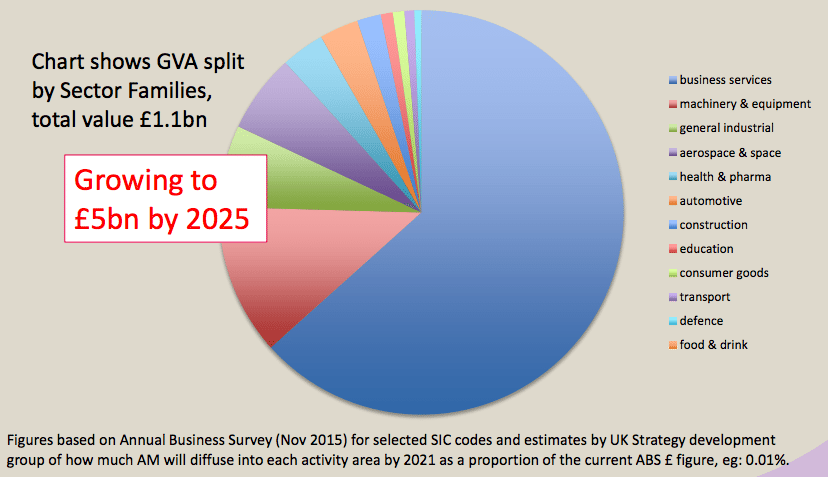

That extra value is the subject of study by Innovate UK. Wilson says, “The order of magnitude for new business is about £1 billion ($1.3b) by 2020 and about £5 billion ($6.5b) by 2025. That’s based on current analysis of the Growth Value Add (GVA) in manufacturing areas and seeing which of them could AM make a difference to.” With most recent full year data valuing the UK economy at £2.21 trillion ($2.85 trillion) at first glance AM’s contribution to the economy seems minimal. However, the UK’s economy is currently dominated by financial services, with almost 80% of GDP related to the sector. Activity in the production sector accounted for 14.6% of GDP or £323 billion ($417b).

Opportunities in 3D printing

For those looking to benefit from the increasing use of additive manufacturing Wilson has a number of insights. “Professional services, which is design, software, consultancy, support, training etc., for the first few years that will probably be the biggest sector to see real revenue here.” Longer term he says “equipment and machinery and then you come onto the likes of aerospace, motorsport, medical etc.”

Individuals looking for work related to 3D printing may also find success, “with companies that we talk to, they are saying the skills we need most are people probably at graduate level who are able to operate the machines, understand the customer requirements, machine settings, machine parameters, material recommendations.” In summary he says, “You’ve got a gap at the technician level.”

At the higher levels investment made 4 years ago is starting to pay dividends. “Our colleagues in the Engineering and Physical Sciences Research Council (EPSRC) have funded a number of centers for innovative manufacturing.” One such center is based at Nottingham University. These centers are now providing, “Graduates and post graduates in additive manufacturing and all the latest disciplines. There is a lot of potential I think at that level starting to come through the universities.”

3D printing provides, “the most interesting motivation for young people to get into engineering and design and production in a generation, if not in 2 generations,” says Wilson. “It’s very multidisciplinary and there’s a big demand there.” However, as additive manufacturing moves into production and creates new opportunities the phenomena of what economist Joseph Schumpeter termed “creative destruction” is also evident. Wilson says, “In quite a few cases we believe there are company’s who’s business won’t be here in 10 years time because it will be completely replaced by additive and 3D printing.” An example is the manufacture of hearing aids, traditional methods have been superseded by AM and companies such as Sonova produce custom-made products in the hundreds of thousands every year.

Additive manufacturing also has a role to play in supply chains and can provide a competitive advantage here. “When you’re not making so much money you suddenly realize, if we could save some money by making these parts … rather than shipping all the stock as well as having higher performance parts, that opens up an interesting number of possibilities,” Wilson explains.

The future of 3D printing at Innovate UK

“The big thing for us on AM is the current funding call. £4.5 million going until the end of July. We’d expect to fund 15-20 projects. We’re obviously very interested to encourage companies to look at this fourth industrial revolution quite seriously,” says Wilson. Those interested in applying for funding can do so here. Wilson says, “Not only will fund companies and consortiums but also the process of going through the application and focusing on a particular area, we can create a lot of interest in this.” There are other benefits to applying, even for those who do not get funding. According to Wilson even projects that are not funded may still go ahead. He say recurring sentiment expressed to Innovate UK is, “after the process of thinking about this, writing an application and talking through with the various partners we’re going to go and do it anyhow.”

Also on the horizon is the national strategy document. The document will be an important publication and the result of “cross-sector thematic work groups that we’ve got running looking at design, standards, materials and processing.” It involves expert participants across multiple fields. Wilson says, “We want to give these groups time to identify areas of quick wins, sharing knowledge around this activity and residual issues.” He clarifies with examples, “what needs research, what needs innovation support and also sharing of best practice. We believe the strategy document will be more powerful if we wait for these groups to complete their work.” He says, “We’re postponing it until next year but there will be an interim update in the autumn.” Wilson explains that this is because, “we are expecting that there could be a national innovation plan, a view on a digital strategy. Its important for any national technology strategy to be properly linked to what’s going on with the national agenda.”

With a budget for 2016/17 of £561 million ($725m) Innovate UK are clearly preparing to ensure the country is not left behind. Although the UK has only around 5% of the global market behind that seemingly small percentage is an important aspect not necessary captured in economic data.

“For know-how the UK is in the top 5 worldwide. That’s what people tell us,” says Wilson.

There is more about Innovate UK in this presentation.