German start-up iFactory3D has announced the launch of its debut 3D printer, the iFactory One.

Targeted at hobbyists, SMEs, and prospective entrepreneurs looking for a round-the-clock prototyping engine, the iFactory One is an FDM conveyor belt 3D printer packed to the brim with frills. Having just received a substantial financial investment from business accelerator Startplatz, iFactory3D is now in the process of jumping its final hurdle with the launch of a crowdfunding campaign on Kickstarter.

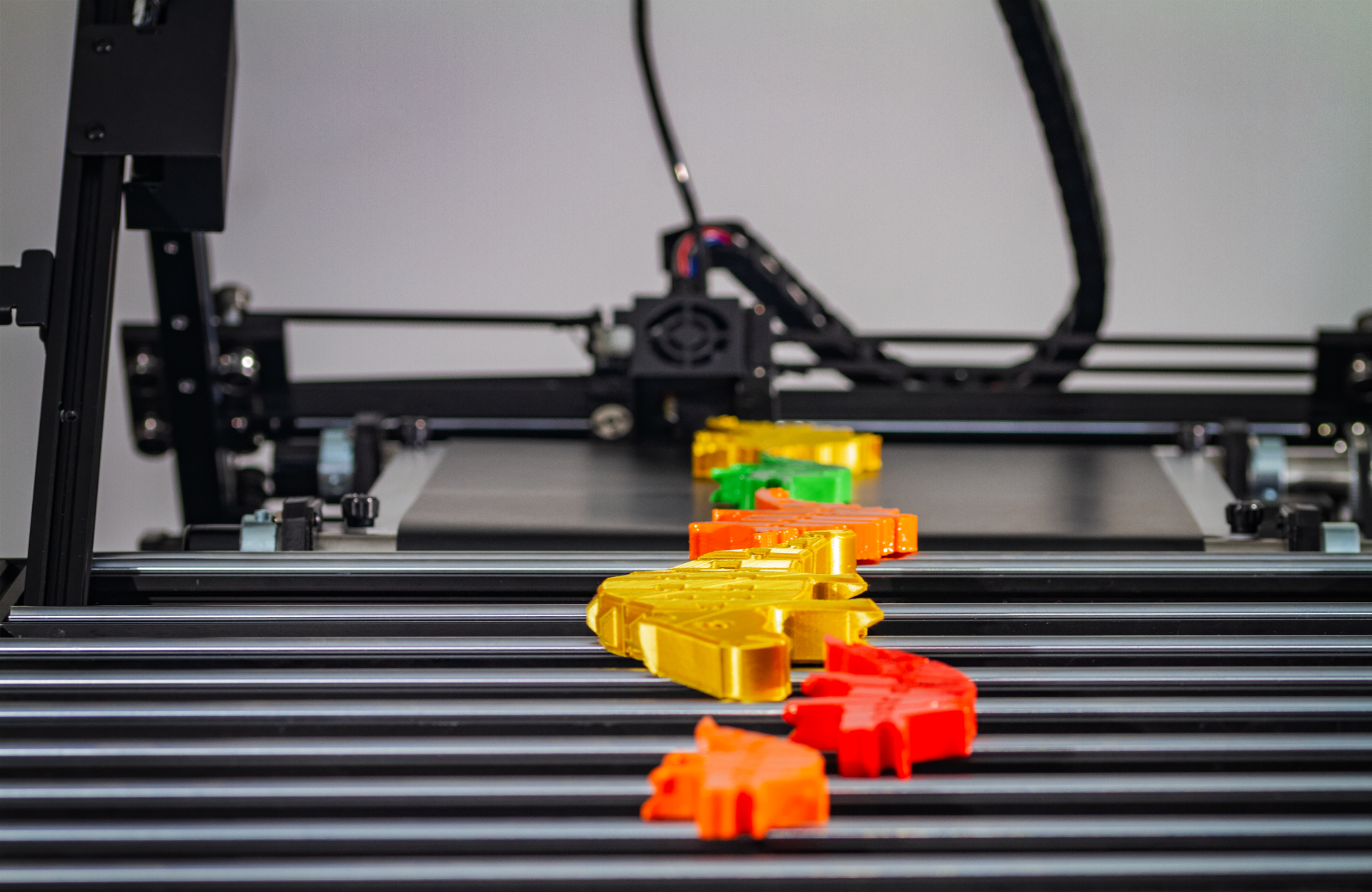

The iFactory One

Seeing as the machine is characterized by its conveyor belt, it features a build volume of (virtually) infinite x 290 x 180mm. The exchangeable hotend is angled at 45° to alleviate the need for an abundance of supports, although complex geometries will still need them. Any parts that do not fall off automatically as a result of the belt’s curvature are removed forcibly when they come into contact with the second line of defense – the printer’s scraper.

The machine itself has a frame measuring 710 x 640 x 500mm, making it feel right at home on a workbench or desk. A maximum nozzle temperature of 260°C enables the system to print with a whole host of thermoplastic filaments, including PETG, PLA, PC, and ABS to name a few.

Most of the printer’s functionality is accessible through the 3.5” touch screen on the front, and connectivity options include SD, Wi-Fi, and USB. To use the iFactory One, users will need to download a company-modified version of the Cura slicer. To top things off in the quality-of-life department, the system also features an in-built HD camera and filament runout sensor.

Error detection with PrinterGUARD

What really sets the iFactory One apart from its competition is PrinterGUARD, the company’s very own embedded AI-based error detection software. The system serves to visually identify the five most common errors that occur during FDM printing: spaghetti, print bed detachment, part warping, stringing, and air printing. Since it is backed by ML algorithms, the software is expected to improve its detection rates greatly over time. The company has also stated plans to train PrinterGUARD to detect up to 20 different types of errors, which will help users improve their print success rates and save significantly on filament costs.

Artur Steffen, CEO of iFactory3D, states: “A private poll of 1,000 3D printer users found that these printing errors occur in approximately 20% of all cases. Before the iFactory One entered the market, error diagnostics and the human aspect led to great losses for manufacturers. But the defect ratio can be minimized by means of the custom 3D solution.”

Technical specifications and pricing

Below are the technical specifications for the iFactory One. The Kickstarter for the machine is now live, with a discounted price of €699 until November 20. The price is set to gradually increase until it reaches its final retail price of €999 by the end of the campaign. Any printers purchased during the Kickstarter campaign are guaranteed to be delivered between December and March. From April 2021 onwards, the iFactory One will also be available through select distributors.

| Build volume | Infinite x 290 x 180mm |

| Physical dimensions | 710 x 640 x 500mm |

| Weight | 18kg |

| Display | 3.5″ 320p touch screen |

| Nozzle diameter | 0.4mm |

| Print speed | 20 – 100mm/s |

| Layer height | 0.03 – 0.3mm |

| Max nozzle temperature | 260°C |

| Operating sound | <70 dB |

| Max bed temperature | 100°C |

| Monitoring | Raspberry Pi and HD camera |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the iFactory One 3D printer. Photo via iFactory3D.