Innovation in the 3D printing industry is coming from all sides now, with some of the most important developments occurring in material science. The more materials we can print, the more useful the technology becomes. What many users of the technology have discovered, though, is that 3D printing allows for the creation of unique geometries that increase the usefulness of certain materials. By printing objects with specific shapes, we can induce important physical properties in our prints.

When it comes to the strength-to-weight ratio of a material, this couldn’t be more important as researchers constantly work to make strong, yet lightweight composites for fields like the aerospace industry. This is where scientists at the Karlsruhe Institute of Technology in Germany come in. Using the Nanoscribe laser lithography printer, which we’ve covered on the site before, PhD student Jens Brauer and his colleagues developed a process for 3D printing microscopic structures that are less dense than water, but stronger than steel. Bauer tells The Conversation that, “This is the first experimental proof that such materials can exist.”

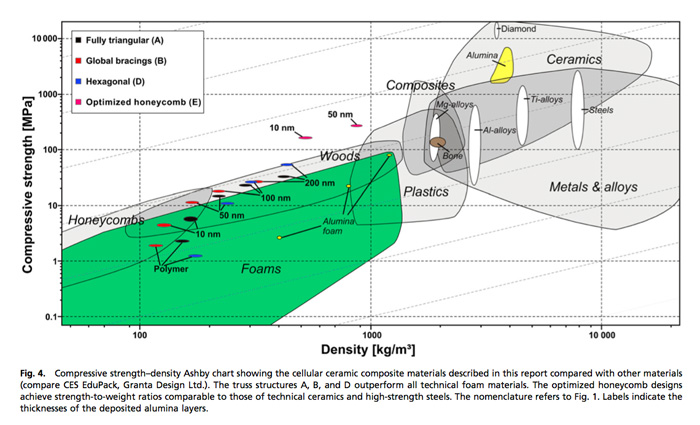

If you look at the Ashby chart above, you’ll see that most materials that can withstand pressures of up to 280 MPa (megaPascals often used to measure stiffness or tensile strength) are metal alloys that tend closer to the denser side of the weight spectrum. There are a couple of exceptions, however. Wood and bone[1] tend to have high tensile strength while maintaining a very light weight, thanks to their porous internal structures. Taking a cue from these natural materials, the team went about designing 3D structures that might exhibit similar properties.

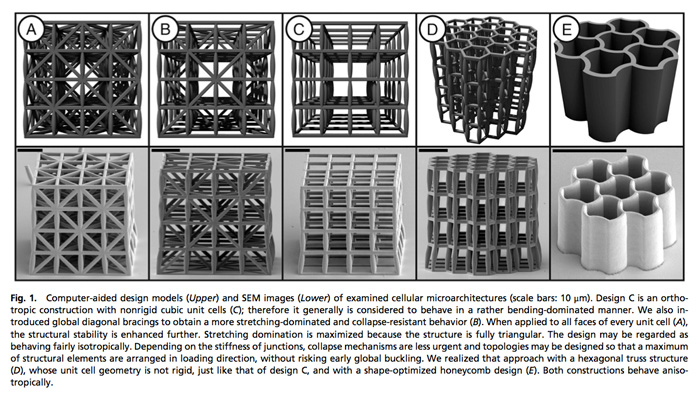

Bauer and his colleagues 3D printed microscopic trusses out of a ceramic material in the shapes you see above. In order to further increase the stiffness of these shapes, a coating of aluminum oxide was applied using atomic layer deposition (ALD). The strongest structure the team was able to create was both lighter than 1000kg/m3 and was able to withstand pressures of up to 280 MPa, with its honeycomb shape and an alumina coating 50 nanometers thick. This makes the material both lighter than water and stronger than some forms of steel, The Conversation points out. Watch it in action below:

At the moment, the Nanoscribe machine only allows for the 3D printing of very small objects. Bauer points out that “one of their newer machines can make materials in the milimetre-range, but that’s about it for now.” With the rapid developments taking place in the industry, however, it may not be too long that the team’s research, published in Proceedings of the National Academy of Sciences, might have real world applications.

Source: The Conversation and PNAS

[1] This isn’t the first time that scientists have tried to model materials after bone.