When you take a week off work, it goes without saying that things will happen while you are away. I was actually taking bets with my nearest & dearest on how many new 3D printers would launch during our holiday – I didn’t win. My money was on two, other bids were none (haha), one, and, bless him, 11 (he’s eight years old)! As it turns out, there have been four – well three new and a new larger version of an existing model. Of the four, three are RepRap derivatives using the deposition/extrusion process and one is based on the stereolithography (SL) process. All of them are open source and proud of it.

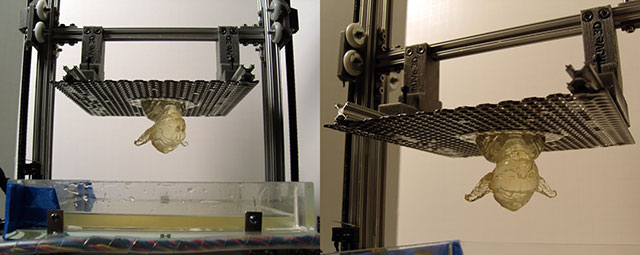

mUVe 1

The motivation for the new mUVe 3D printer is clearly to build on the momentum from the success of the Form 1 and the B9Creator in bringing low-cost high-resolution 3D printing to everyone. The brain child of Dean Piper the mUVe 1 is in Beta since its conception in January and is seeking a first round of funding on Indiegogo to enable Dean to get visibility on whether he can gain traction for this 3D printer. Dean has been working with extrusion based 3D printers for a number of years and acknowledges the success realized with these printers but he believes that “Stereolithography technology has far too long stayed in the hands of professionals and away from a mass majority of the thinkers and tinkerers this planet has to offer.”

Furthermore, the intention behind this project is for the mUVe 3D printers “to be as upgradable as possible to save cost over the product’s life-cycle, and [for] them to be easy to maintain. They are simpler mechanically than current extrusion based machines and use almost all similar parts to current extrusion machine technology, including the electronics. This makes the mUVe 1 incredibly accessible for the self-builder or anyone that already has a 3D printer and wants to try and build their own.”

A time lapse video of the mUVe in action can be seen below.

Cyrus

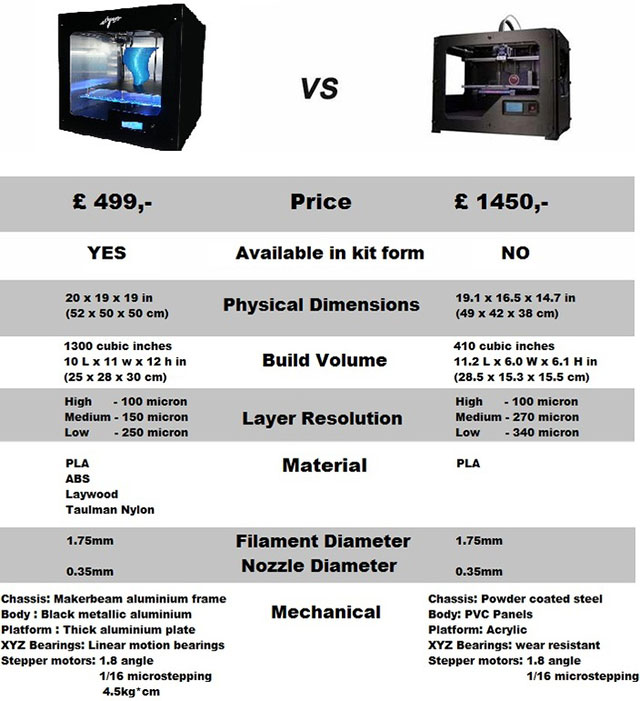

Cyrus is an open source, low-cost extrusion 3D printer that comes with a rigid aluminum casing in kit form and can, allegedly, be assembled in couple of hours. Take a look at the spec sheet in the image below for the data on this system and it also gives you an idea of where it is being pitched.

The developers want the Cyrus to “close the gap between consumers and makers” but that is not a new aim. Again, the ethos behind the Cyrus is fully open source based on the premise that “3D printing belongs to the world and each person should be able to have access to it. From kids to entrepreneurs who have great ideas but cannot afford prototyping.” The Cyrus can be purchased as a kit or fully assembled for £499 or £699 respectively (with optional add-ons). It was launched 5 days ago and has raised just over $7k with 30 days left to reach the $30k target.

AW3D XL

The larger build envelope can build models as large as 12″X 8″X 7″, with the features that all Airwolf 3D printers offer, namely that they easier to use, easy to maintain and print faster and more accurately than comparable platforms, according to the organization. The assembled AW3D XL is priced at $2295 with a two week lead time from ordering and a six month warranty as standard.

Build Envelope: 12″X 8″X 7″

RAMBo Circuit Board

Temp Controlled Heated Bed

Minimum Layer Height: 80 Micron

Maximum print speed: 150 mm/sec

Materials: PC, Nylon, ABS, PLA, PLA-Wood

Power Supply: Internal 360 W

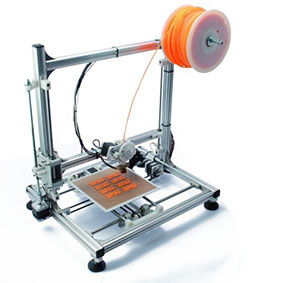

3Drag

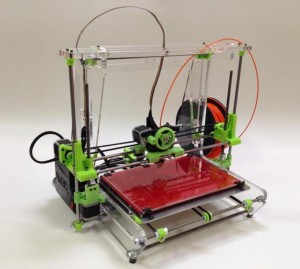

The new 3Drag 3D printer comes from Italy and has been developed by a team led by Boris Landoni over many months. The starting point for the development was a RepRap Prusa Mendel 3D printer but with the aim improving installation with a simplified assembly process while retaining Mendel quality performance and compatibility with RepRap electronics, firmware and software for easy updates.

The result, according to the team, is a more stable 3D printer structure involving simple sequences and the elimination of moulded plastic parts and M8 threaded rods in favour of aluminum profiles with shapes designed for easy fixing. The 3D printer is also lighter and more rigid as a consequence with reduced vibrations and noise.

Technology: FFF (Fused Filament Fabrication)

Materials: PLA and ABS

Build Envelope: 20 x 20 x 20 cm

Medium size printing plate: 21.5 x 21.5 cm

Typical print speed: 120 mm / sec

Maximum print speed: 300 mm / sec

Miniumum layer height: 0.781 microns

Weight: 8.7 kg

Power supply: 12V 3A max

Hot extrusion with nozzle of 0.5 mm, NTC 100K and steppers

Controller: Sanguinololu 1.3a or compatible

FTDI USB 2.0 to Serial, Arduino compatible

Source: 3Drag