Last February Utrecht University (UU) announced it would invest €775.000 to create a facility to study possible applications and development of bioprinting technologies, in particular to analyze the possible relationships and synergies between plastic based desktop FDM/FFF 3D printing and biofabrication.

That punctually happened and now the knowledge collected in these past few months will be passed on to students who register for the 5 days “3D Printing and Biofabrication” course organized by the Faculty of Medicine from July 14th to the 18th.

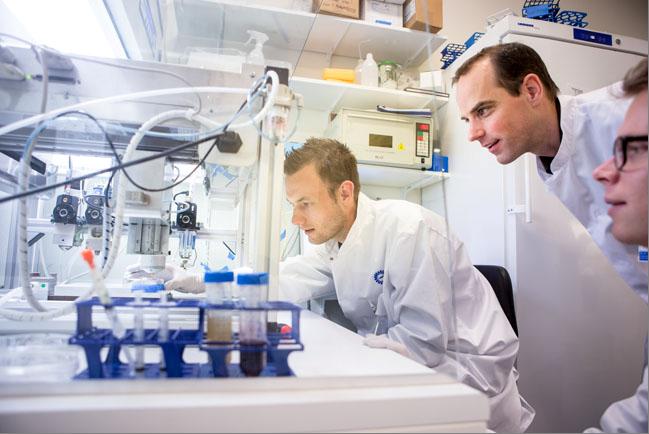

The course, led by Dr. Jos Malda, is targeted at master level students with bio/medical, chemistry and/or engineering backgrounds, who are interested in the application of 3D printing in the field of organ and tissue fabrication. Just like the facility first set out to do, the lessons will not only focus on bioprinting and bioplotting but will begin with an in depth study of “standard” 3D printing technologies as a way to convey the way additive manufacturing works.

The program, which you can check out here, spans five days with 5 to 6 contact hours per day and 2-4 hour assignments, with a 1 day hands on workshop. Basic cost is €800 (€1000 with housing) and it can be combined with the Regenerative Medicine course for a reduced price

The first two days will be centered on plastic and metal 3D printing processes, using an Ultimaker and the Cura software (we are in the Netherlands, after all) for practical demonstrations. Form the third day on, the focus will shift entirely toward bioprinting, with an introduction to regenerative and stem cell based medicine and overviews of different biofabrication technologies. The fourth day will be dedicated to the more practical aspects of 3D bioprinting, with a focus on bone and cartilage.

The smooth transition from desktop 3D printing to bioprinting may be surprising and yet a bioprinter – and all 3D printers – work in much the same way, by creating objects adding digital slice after slice. That similarity is exactly the base that the Utrecht University bioprintingh facility was founded on, and that is very likely going to be the base for a growing part of tomorrow’s healing processes.