Researchers at ETH Zurich have created a silicone artificial heart using a 3D printer. According to the Swiss group, the silicone structure is “the first entirely soft artificial heart.”

Developed at the Functional Materials Laboratory by doctoral student Nicholas Cohrs and Professor of Functional Materials Engineering Wendelin Stark. Having fabricated the heart, the structure was evaluated with the help of the Product Development Group at ETH Zurich. This subsequent research was published in Artificial Organs.

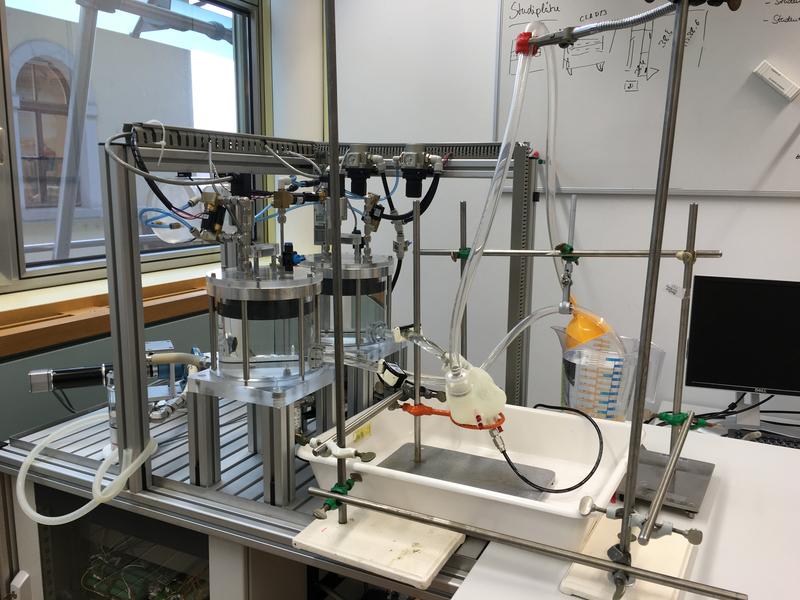

Gif shows testing of the silicone artificial heart. Images via ETH Zurich.

Heart makers

The artificial heart was produced with a 3D printing, lost-wax casting technique which was similarly implemented to create this year’s Oscar awards. This means 3D printing was used to create the intricate molds of the silicone organ.

Cohrs explains the heart “is a silicone monoblock with complex inner structure” and weighs 390 grams with a volume of 679 cm3. In its evaluation, the team found the silicone materials could only last about 3,000 beats which amounts to a lifespan of less than an hour. However Cohrs explains,

This was simply a feasibility test. Our goal was not to present a heart ready for implantation, but to think about a new direction for the development of artificial hearts.

Despite this doctoral student Anastasios Petrou, part of the Product Development Group Zurich, believes the “system is probably one of the best in the world.”

Zurich Heart

The silicone artificial heart is part of the Medicine department’s Zurich Heart Project which brings together 20 research groups from Zurich and Berlin. The team explains the motivation for the project is to develop a better solution for artificial heart organs.

The researchers explain current heart pumps are not sufficient and lack the physiological factor of a pulse. Cohrs thereby states the “goal is to develop an artificial heart that is roughly the same size as the patient’s own one and which imitates the human heart as closely as possible in form and function.”

There is definitely a need for artificial hearts, as ETH Zurich points out, there are 26 million people suffering from heart failure in the world and a prevalent lack of heart donors. Blood pumps are currently used as a substitute or as a stopgap while a patient waits for a donor heart or to recover from the heart problem. ETH Zurich’s researches hope with future research they can create a new device to provide a vital solution to heart problems.

3D printed hearts

3D printing has been explored in this field many times before as Georgia recently constructed a 3D printed heart valve to be used in surgery simulation. While elsewhere, an engineer turned to 3D printing to save his heart. A number of academic institutions are researching into 3D printed blood vessels such as Boston University’s development of a 3D printed vascular patch to promote blood vessel growth.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows the silicone artificial heart. Image via Zurich Heart.