Multi award-winning 3D printer provider Markforged announced that Dunlop Systems and Components, a UK-based automotive manufacturing company, has been using its machines to create custom tooling, saving thousands of dollars in the process.

As its tooling division had become a bottleneck, Dunlop Systems purchased a Markforged desktop 3D printer in order to overcome problems associate with outsourcing custom production. In particular, the company is now reaping the benefits of its 3D printer to help bring an electric car to the market for a large automotive company.

“Since we’ve had it, we’ve never looked back. It’s the best thing we’ve ever bought,” commented Mark Statham, Production and Engineering Manager at Dunlop Systems and Components.

“People are seeing tooling coming onto the shop floor more frequently than they ever did. I think they’ve had more tooling in the last six months than in the last five years.”

Bringing 3D printed production operations in house

Based in Coventry, Dunlop Systems and Components is an independent company formed in 2007 through a management buyout from Trelleborg AB, a Swedish polymer engineering firm. The company specializes in producing anti-vibration solutions for cars including automotive air suspension components and electronic control systems for OEM and aftermarket vehicle applications.

Dunlop Systems houses a number of old machinery and in-house tooling at its facility that frequently need replacement. For this, typically the company would send internal and customer tools to a third-party toolmaker. This would often extend shipping-related lead times, and further delays as a result of customer design changes, inflating the costs, and sometimes creating losses. “You spend all that money and you wait two or three weeks for it to come in, and the customer then phones you up to tell you what they want changed,” explains Statham.

Seeking an alternative, Statham attended a seminar held by Mark3D, a UK reseller of Markforged 3D printers. “I went along very open-minded, and as soon as I saw what the printers could do I thought, why can’t we do our own tooling?,” states Statham.

There, he learned of the capabilities of Markforged’s 3D printers. Statham identified the company’s continuous carbon fiber as a suitable material for producing robust tooling strong enough to withstand corrosive environments. After discussing the 3D printer with the Dunlop Systems Director, a review was carried out to determine if the system would be a good fit for the company, resulting in the purchase of the Markforged 3D printer.

Bottleneck eliminated

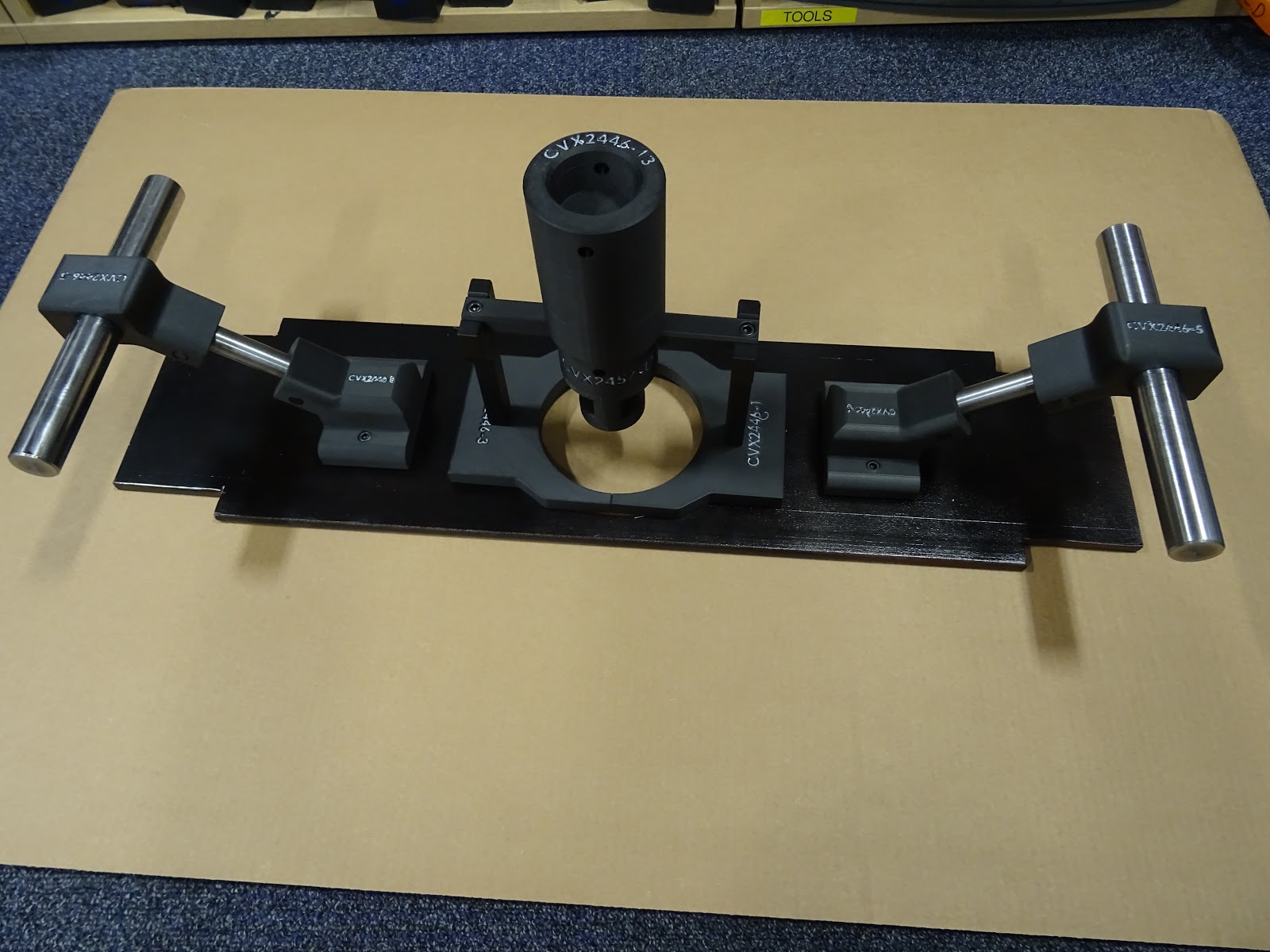

Since commissioning the Markforged 3D printer, the Dunlop Systems tooling division has found several applications for its use. The team has used it for the production of prototype parts for electric cars to gauges and molds. Tooling can now be tweaked internally according to the customer’s needs on demand, cutting lead times and costs drastically. “Our department’s almost got bragging rights because we can now say that we don’t hold up any program. If you want something done, we can now print it within a couple of days. So we’re not holding anyone up,” added Statham.

The Onyx and continuous carbon fiber materials from Markforged have also proven to be a perfect fit for Mark’s team. For example, they have replaced the nylon material used in some fixtures with Onyx material. During hot summers, the nylon would warp, however using Onyx the tooling is ensured to withstand the heat. “We’re now in the process of replacing, where possible, all our tooling with Onyx,” says Mark. The team usually spends around £20,000 ($24,300) on tooling, however this year the department has cut its spending to £11,000 ($13,300) thanks to additive manufacturing. Statham adds that:

“We’ve already saved £20,000 in just six months, so we’re on target to save £40,000 this year if we carry on this way.”

Dunlop Systems is now using the Markforged 3D printer to print custom tooling for a beta electric vehicle for a large, unnamed automotive company. Currently, the car is on the road equipped with 3D printed Onyx prototype parts as well. Previously, Dunlop Systems was spending large sums of money to manufacture the prototype tooling by outsourcing, with one part costing the team about £500 ($630) to fabricate. Using the Markforged 3D printers, the same part only costs £15 ($18) to print, therefore saving the company thousands.

Updates from Markforged

Markforged 3D printing were also used recently in a separate case study at a leading global energy services company. The firm used the Mark Two 3D printer to support and maintain parts of its production line, leading to a reduction in turnaround time, and cut down on costs.

In March 2019, the company closed a Series D funding round with a value of $82 million and subsequently expanded its operation to a European HQ in Dublin. It has released a variety of new products since, including a flame-retardant composite material and a new AI technology platform named Blacksmith, during RAPID + TCT 2019.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows sample parts made on the Markforged Metal X 3D printer. Photo via Markforged.