Microscale 3D printing systems specialist, Boston Micro Fabrication (BMF), has launched what it claims is the ‘first and only’ micro-precision 3D printer for short-run industrial production, the microArch S240.

Modeled on BMF’s patented Projection Micro Stereolithography technology (PµSL), the firm’s latest printer features additional advanced materials, a greater build volume, and higher printing speeds.

“Until now, this coveted combination of quality, strength and resolution has been missing from industrial production, particularly for use cases that require high precision and micron level resolution,” said John Kawola, CEO-Global of BMF. “With the microArch S240, users can finally make end-use micro parts at speeds that are required for production, with resolution, accuracy and precision that is true to CAD. Smaller parts no longer need to mean bigger headaches or bigger price tags for manufacturers and engineers.”

Micro-precision 3D printing

In February, BMF announced a global launch and rebrand of its microArch 3D printers, which were previously known as nanoArch, after rolling out its systems in Asia. However, BMF isn’t the only micro-precision 3D printing specialist, with several other firms are making advancements in this field.

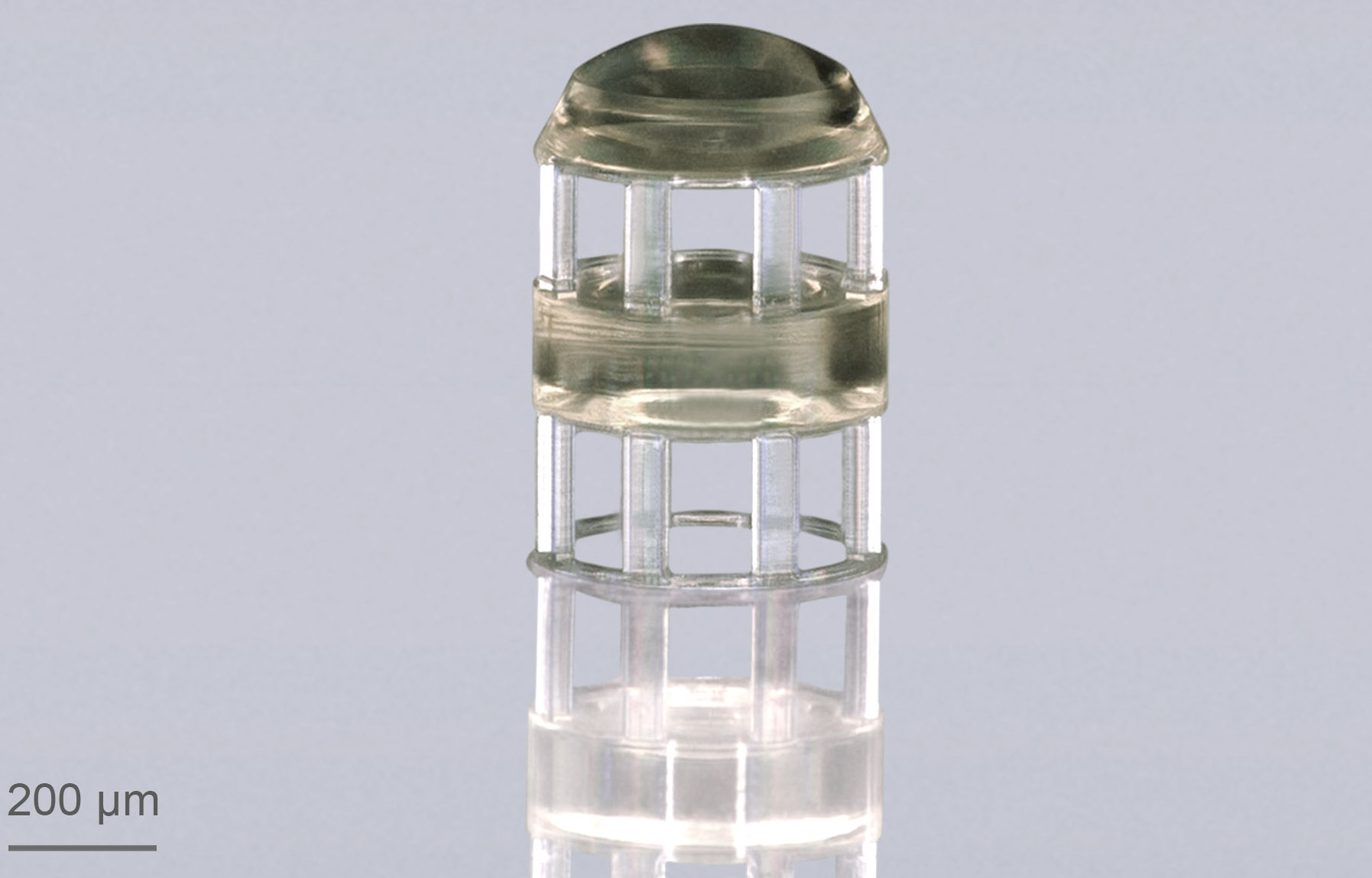

Two-photon 3D printer manufacturer Nanoscribe provides systems that leverage two-photon polymerization technology to produce parts with resolutions as low as 200 nanometers. The German firm recently released a new photoresin which it says will take fabricating micro-optical elements “to the next level.”

Elsewhere, Nanofabrica, a Tel Aviv-based developer of precision additive manufacturing technologies, commercialized its micron-level resolution 3D printing technology in March last year. Its technology is based on a Digital Light Processing (DLP) engine, and Adaptive Optics (AO), a technology used to enhance image distortions in optical devices.

Most recently, researchers from Yokohama National University (YNU) devised a new 3D printing method capable of 3D printing multicolor microstructures using different materials, using a stereolithography (SLA)-based technique.

The microArch S240

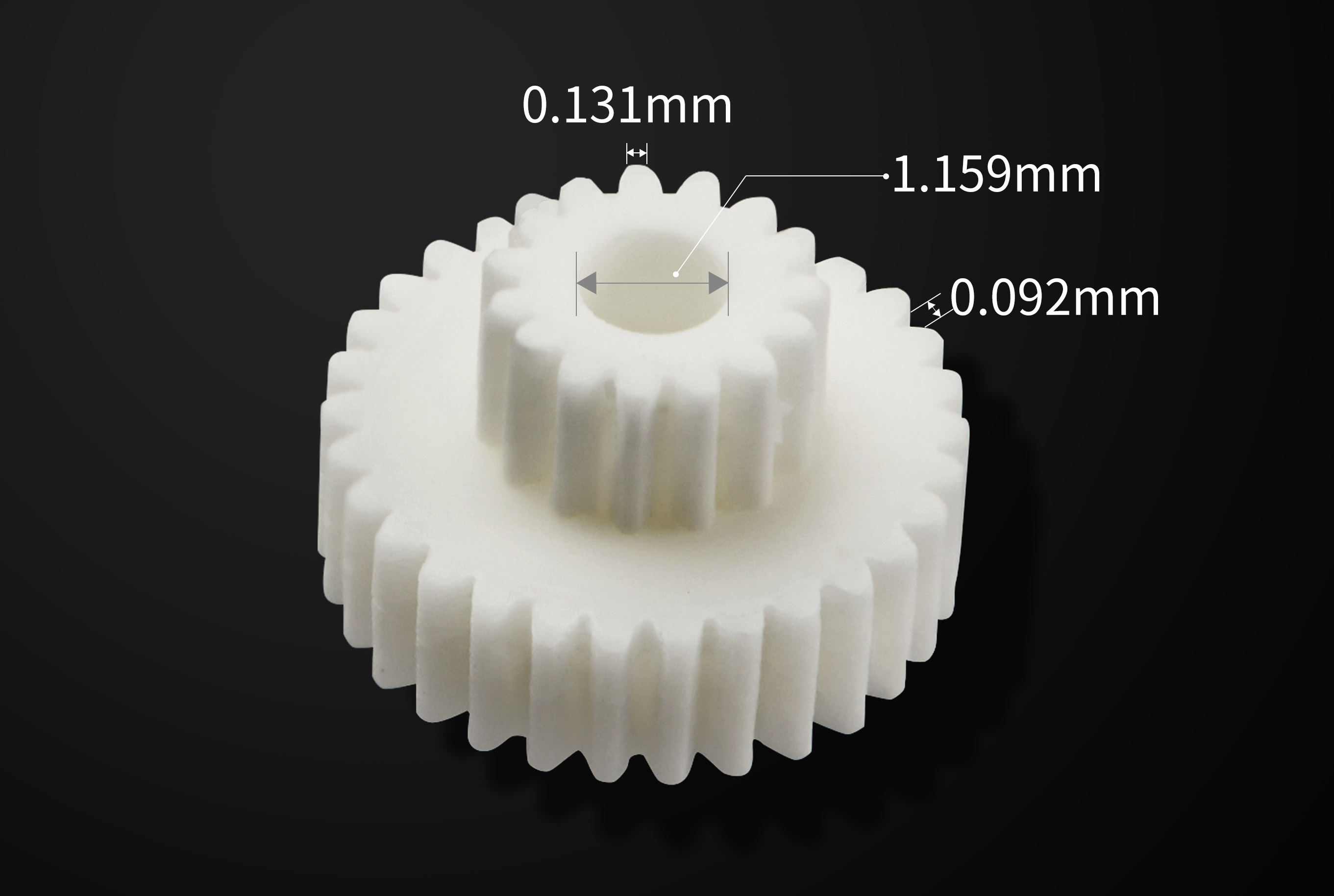

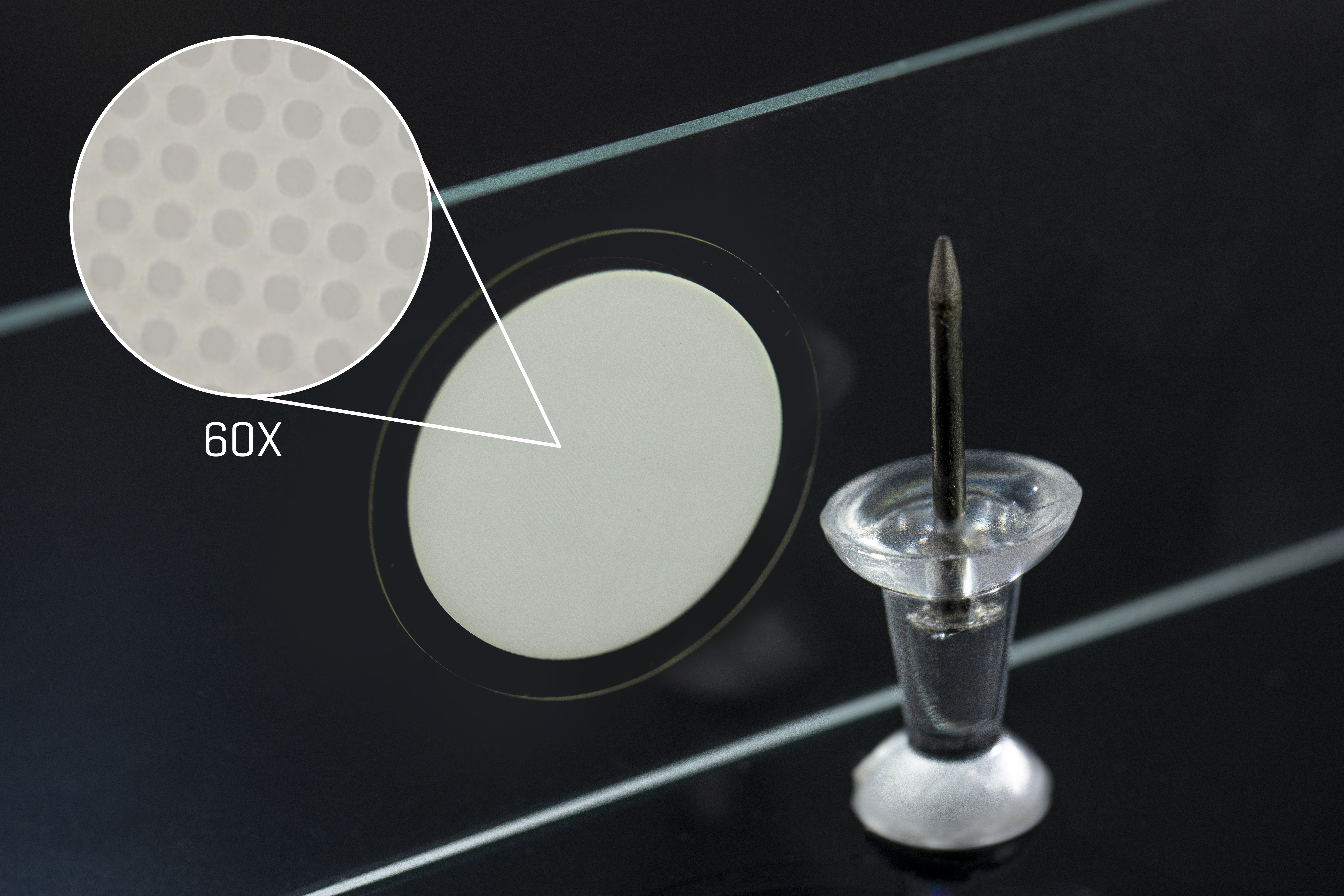

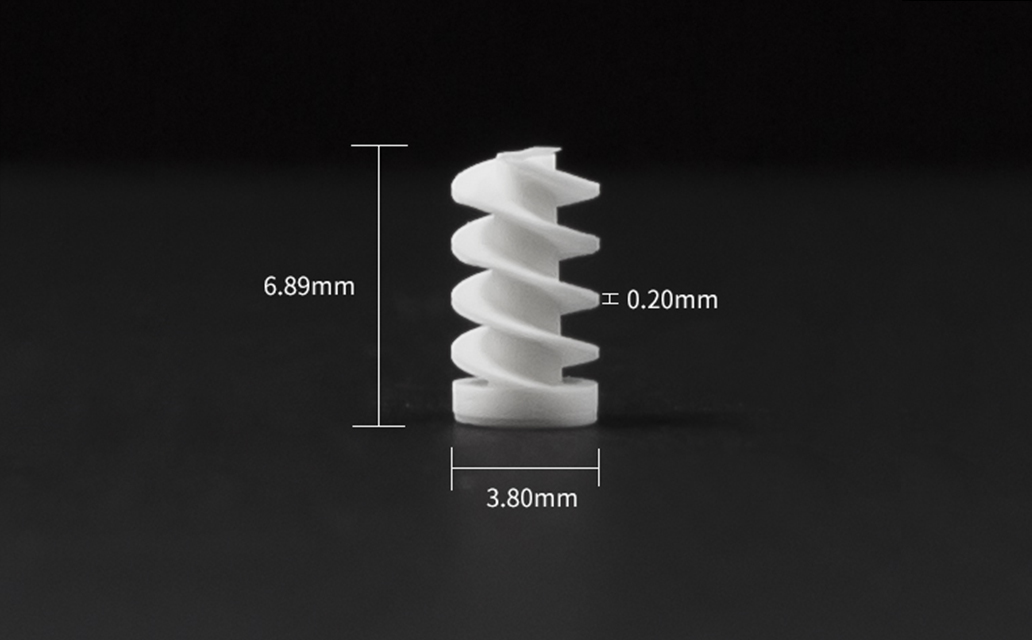

Using UV light flashes at micro-scale resolution, BMF’s PµSL technology enables rapid photopolymerization of a layer of liquid polymer to create detailed, replicable parts. Reportedly able to print microstructures more than 100 times smaller than a human hair, the technique is ideal for end-parts and prototyping across sectors such as microfluids, electronics, medical device manufacturing, and biotech, among others.

The microArch S240 was designed with a larger build volume (100x100x75 mm/750 cm) to suit industrial production demands, and is able to print up to 10 times faster than previous models due to its advanced spreading mechanism. This means larger parts, or a greater number of smaller parts, can be produced while maintaining the 10 µm resolution and +/- 25 µm tolerance of its other printers.

Capable of printing industrial-grade composite polymers and ceramic, the microArch S240 is also able to produce stronger functional micro-precision parts, as it can handle higher molecular weight materials with viscosities of up to 20,000Cp.

BMF RG collaboration

BMF has collaborated with chemical specialist BASF to develop a new functional engineering material for use on the microArch S240, called BMF RG. The material, derived from BASF’s Forward AM Ultracure3D photopolymer resin line, possesses high strength and durability characteristics suitable for industrial production demands.

“The new BMF RG material from the Forward AM Ultracur3D photopolymer resin line will enable users to achieve ultra-high resolution of their parts,” said Oleksandra Blacka, business development manager for Photopolymers, Medical, and Dental at BASF. “The microArch S240 printer is addressing a market that has previously been unserved. This collaboration will now enable customers, especially in the medical industry, to assemble complex items that were too small to handle on previous printing platforms.”

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows micro ceramic medical filter 3D printed with the microArch S240. Image via BMF.