Using state of the art bioprinting technology, scientists were able to 3D print human tissue with a functional vascular network for the first time, moving us closer than ever to a day when we can replace damaged or aging organs at the push of a button. We’re still not there, of course; bioprinting is an incredibly sophisticated endeavour. Especially considering that we still don’t entirely understand exactly how the human body works in a lot of ways, including how cells just “know” how to form a functional circulatory system.

But for the first time, scientists from the universities of MIT, Harvard, Stanford and Sydney have all successfully bioprinted tissue with an intact and functional vascular network. These bioprinted organs are just extremely early prototypes, but they are a very important step towards replicating a complete and functional replacement of a human organ.

“While recreating little parts of tissues in the lab is something that we have already been able to do, the possibility of printing three-dimensional tissues with functional blood capillaries in the blink of an eye is a game changer,” says University of Sydney’s, Dr Luiz Bertassoni “Of course, simplified regenerative materials have long been available, but true regeneration of complex and functional organs is what doctors really want and patients really need, and this is the objective of our work.”

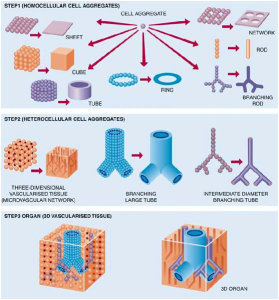

The scientists and researchers used what is essentially an industrial manufacturing process to fabricate the vascular network by creating a mold before building the organ tissue around it. Using a bioprinter – more or less a smaller and more complex inkjet printer – the scientists fabricated a network of tiny interconnected fibres made from a sugar-based molecule called agarose. This sugar “mold” was then immersed in a cell-rich protein-based hydrogel solution that solidified once exposed to light. Then, the network of bioprinted fibres was removed and replaced with human endothelial cells. Within a week those cells had self-organized and formed a series of stable capillaries.

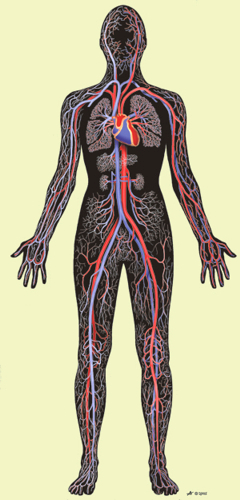

A common analogy employed to describe a city’s system of streets and highways is often to refer to them as the city’s circulatory system. It’s an apt comparison, but, unfortunately, it is an incredible oversimplification compared with the human body. So, to even scratch the surface of how complex the human body’s circulatory system is, you would need to expand that analogy and include more than just the streets, highways, freeways and thoroughfares. You would need to incorporate large shipping lanes, railroad networks and air traffic pathways while also including the smallest least travelled of footpaths, such as sidewalks, hiking trails, the stepping stones in your backyard and even little used paths in forests and wildernesses. And that level of intricacy barely comes close to the level of the circulatory system that is in our body.

Think about that next time you 3D print a Yoda head, and imagine trying to replicate that on a microscopic level using essentially the same technology. We’re not there yet, but we just got a little bit closer.