The Netherlands based 3D printing firm Additive Industries has announced its new flagship 3D metal printer, the MetalFAB-600, complete with a build volume five times larger than that of its sister model, the MetalFAB1.

The MetalFAB-600 will further build on its predecessor with new automated key production processes and greater robustness, and is designed to achieve the lowest cost per part as is possible. Additive Industries will officially present the new model towards the end of 2021.

“Right now it is crucial for Additive Industries to develop and innovate,” said acting CEO and co-founder Jonas Wintermans. “A larger build volume opens doors to more applications and more productivity. Larger build jobs also mean a need for higher laser power and maximum robustness because users want their parts to reach the finish line when printing multiple day jobs.”

The new MetalFAB-600

The MetalFAB-600 comes equipped with a build size of 600×600 mm and 1,000 mm Z-height, which according to Additive Industries is one of the largest volumes currently on the market. Designed to be highly productive, the printer will offer a deposition rate of up to 1,000 cc/hour and will utilize 10 1kW lasers. The MetalFAB-600’s platform is engineered to facilitate further expansion of the build volume, and thus productivity, as and when the need arises in the future.

The new printer will also see the automation of key production processes, such as powder handling, alignments, and calibrations, to maximize machine output. To this end, the MetalFAB-600 will be geared towards the traditional casting and machining industry when it comes to the market.

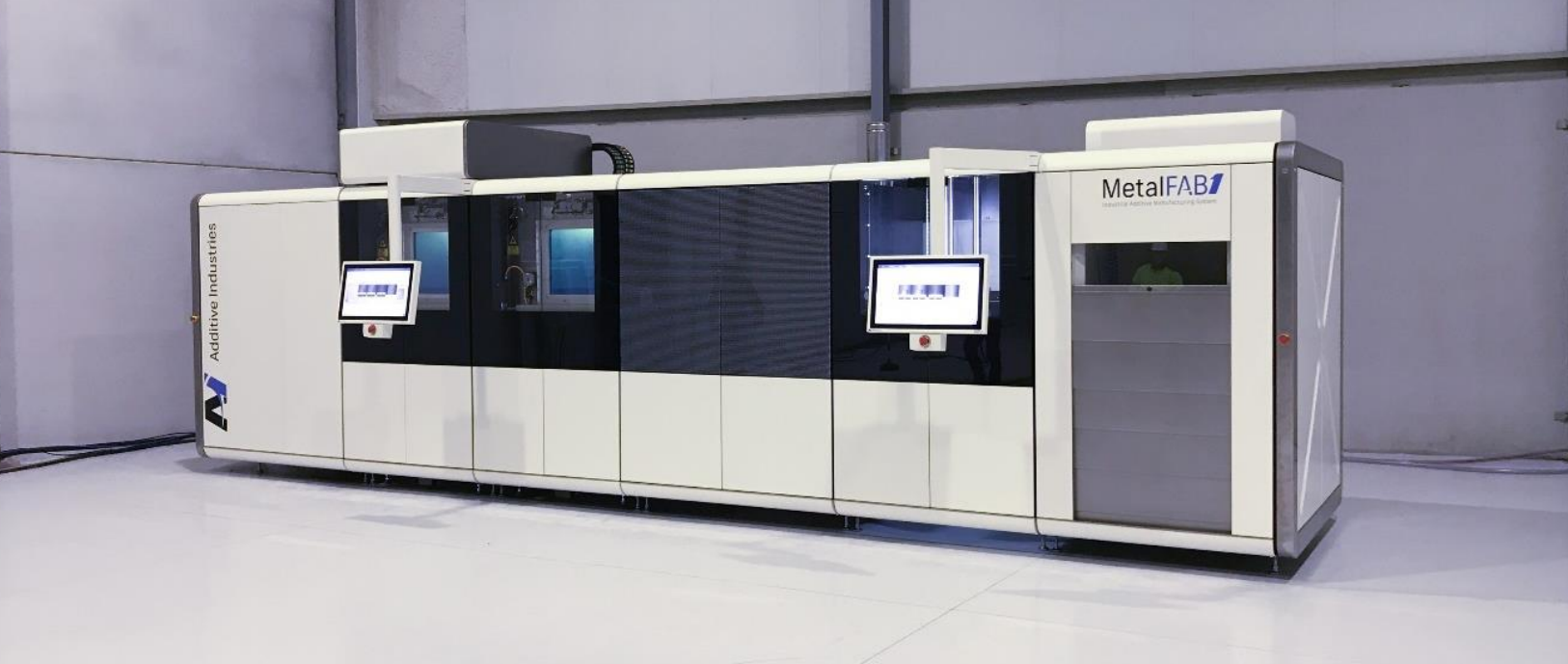

The new machine builds on the back of Additive Industries’ MetalFAB1, a powder bed fusion 3D printer initially unveiled at Formnext 2015 in Frankfurt. The system can be used with any metal powder, although it does include presets for commonly used metals such as titanium and aluminum. Since its launch, customers of the MetalFAB1 have included Alfa Romeo F1 Racing and German multinational automaker Volkswagen. Last year, an unnamed California-based aerospace company purchased six of the firm’s MetalFAB1 systems, bringing its installed base of MetalFAB1 machines to ten.

In addition to the launch of the new MetalFAB-600, Additive Industries announced it would continue to develop the MetalFAB1 in order to increase the simplification of the printer and improve its laser power.

Change at the top

Due to the importance of this project to Additive Industries, acting CEO Mark Vaes will resume his role as CTO of the firm in order to oversee the MetalFAB-600 development team. Over the past few months, Vaes has been combining both roles. Now the firm’s co-founder Wintermans will take up the helm as acting CEO.

“The new MetalFAB-600 project is very relevant for our customers and therefore important for Additive Industries,” he said. “The existing MetalFAB1, which will be developed even further in terms of simplification and laser power, excels in building long and heavy jobs up to 150kg. Its new sibling, the MetalFAB-600, should build on that knowledge.

“We have an excellent team in place, led by Mark, and are confident to be able to enrich our industry with this new model, as well as with our current portfolio.”

Earlier this year, Additive Industries received a €14 million investment from its shareholder, Highlands Beheer, an investment company of the Wintermans family. Additive Industries intends to use the funds to expand its product portfolio, accelerate its technology roadmap, and strengthen working capital.

Additive Industries was founded in 2012 by current acting CEO Winterman to diversify the Highlands Beheer business portfolio, and has since continued to invest in Additive Industries growth. In February 2019, Highlands Beheer provided a €10 million loan to Additive Industries alongside fellow shareholders BOM Brabant Ventures.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Additive Industries will present the MetalFAB-600 towards the end of 2021. Image via Additive Industries.