This is part three in a six-part series covering 3D printing developments in Taiwan. For the other parts in the series, find parts one, two, four, five, and six here.

As a small nation, Taiwan may not be able to pack its borders with a vast number of 3D printing companies, the way the US can, but the businesses focused on this technology are definitely keeping pace with those from more powerful countries around the world, if not going above and beyond them. In this regard, Taiwan’s biggest 3D printing service bureau, DETEKT Technology Inc., is a shining example.

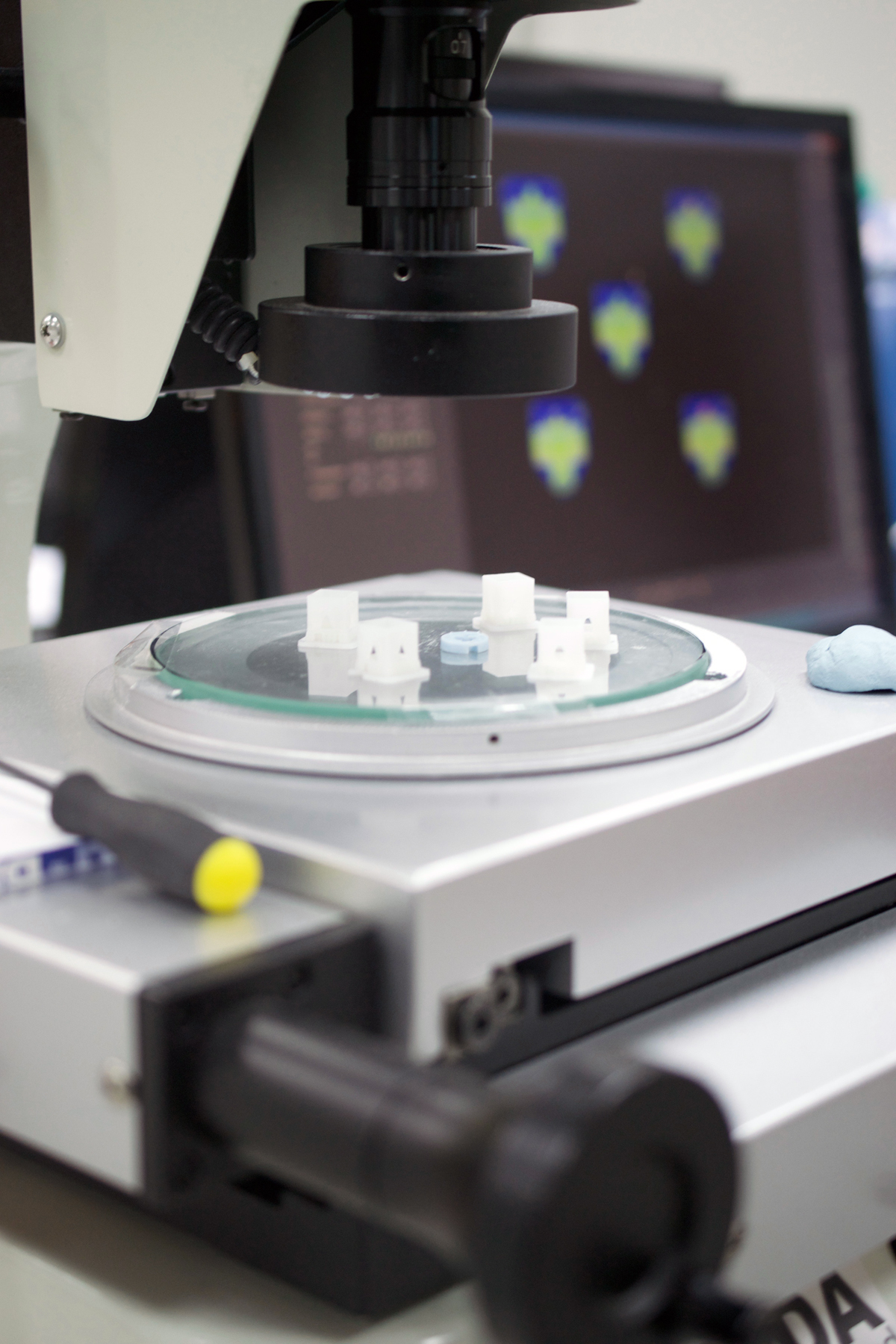

DETEKT is the first 3D printing service in Taiwan to feature a sterile clean room for medical and dental manufacturing. Entering this production area requires, first, passing through an airlock-type chamber, where workers don sterile suits before passing into an adjacent room currently containing an EOS laser sintering machine and a DWS DLP system. DICOM data captured via CT or MRI scans from all over the world may be sent to DETEKT, where their expert engineers work with customers, using software from Materialise, to craft custom solutions for medical purposes. Combining the medical expertise of their customers with the design and engineering knowledge of their staff, the firm is able to create 3D printable surgical guides, implants, and models that can then be sent for production in their clean room.

“Almost 60% of our revenues come from the medical sector,” says DETEKT CEO Peter Chiu. “Our customers upload their CT scans to the cloud and my engineers will download these files and redesign, with a specific function. And, after that, my designers will transfer the stl file here to our EOS and DWS machines. Custom, 3D printed surgical guides and implants are our main business.”

For instance, a young engineer who studied at Penn State described how the firm produced surgical wafers, meant to guide a perfect jaw adjustment operation. First, one wafer was placed on the mandible, as the upper jaw was cut, detached from the skull, and aligned into position onto the wafer. After being reattached in its new location, this guide was replaced with a second wafer that would determine the placement of the mandible. With the wafer situated under the maxilla, the lower jaw was then cut and moved to its new location below the wafer and reattached in place. In the end, the custom guides were ideal in removing uncertainty from the procedure and reducing surgery time dramatically.

While such medical services are going to become increasingly common, DETEKT is already focused on the future. The firm is in the process of purchasing metal sintering machines to create titanium implants. “Are you familiar with SISMA systems?” CEO Peter Chiu asks me. After telling him that I am, but that I don’t know much about their quality, he says, “Well, then I will be the pilot case!” In addition to the TRUMPF laser-powered SISMA system, he has purchased an EOS metal sintering machine.

“We purchased the EOS M290,” Peter says, “because it is a high-level machine because most of our customers are in the medical industry. The accuracy is important, especially in regards to the roughness of a part for implantation. But, we also purchased the SISMA machine because it is almost an open platform for all kinds of materials.”

DETEKT also hopes to supplant its dental 3D printing services, which rely on DWS’ portfolio of materials and in-house dental scanners, with customer-focused dental software. One day, he envisions dental labs from all over owning complete solutions for 3D scanning, modeling, and printing. In fact, Peter, seems to have a clear vision of the future and a strong understanding of the complete ecosystem of digital manufacturing. In addition to this complete dental pipeline, DETEKT sells virtual surgery simulators from Surgical Science. Like 3D Systems’ Simbionix subsidiary, Sweden’s Surgical Solutions produces haptic VR devices for rehearsing virtual surgeries. From VR to 3D printing, Peter is prepping for the complete mixed reality ecosystem that is starting to form as we speak. Because DETEKT also performs 3D printing for design projects, with a talented team of artists, I wouldn’t be surprised if they began selling haptic styluses for 3D modeling as well.

Outside of engineering and printing, DETEKT also retains industrial systems. They are an EOS reseller, but uniquely, they also sell Optomec’s Aerojet machines for electronics 3D printing, too, with Peter telling me that some firms in mainland China have purchased multiple units. This is a very interesting tidbit, as these machines cost half a million dollars and perform the very niche function of spraying conductive tracks on curved surfaces. So, what these Chinese businesses want with them could be very important, once that information becomes public. But, as with many Optomec customers, the use cases are top secret, as were many of the things I saw, while visiting the beautiful, small nation of Taiwan.