With the flourishing popularity of 3D printing technology in the world, many people wonder whether it will replace industrial production in the future. This is a common question asked by people who have a fairly vague idea about 3D printing, without being aware of the nuances associated with the technology – primarily, the fact that it is a relatively long process to 3D print a single object as compared to the speed of mass production injection technology. On the other hand, the cost of individual parts or a low-volume production run with 3D printing technology is incomparably lower than in the case of injection molding, where the creation of a single mold can, in some cases be a multiple of the price of that same low-budget 3D printer.

But what if we combine the two technologies and use 3D printers to print just the molds? I.J. Paliga was one of the first companies in Poland that decided to check it out. Will it be a revolution in the production of series production after a few hundred copies? This may be revealed in the next few months, as the company explores the potential benefits of 3D printed molds.

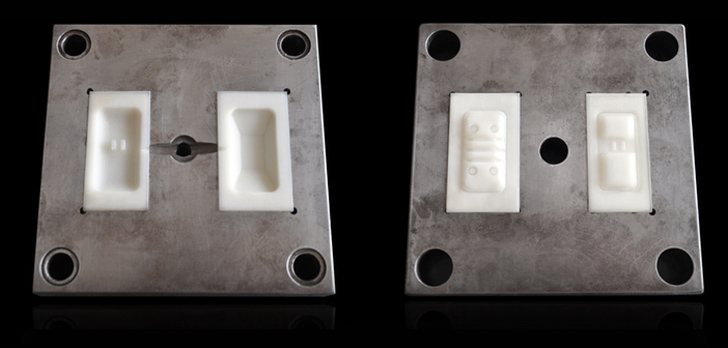

I.J. Paliga has recently started manufacturing their injection molds in two variations: either as a single injection mold, mounted directly on an injection or as an inserts shaping, mounted onto a steel universal housing. To do so, they are using 3D Systems 3D printers equipped with MJM technology, specifically a ProJet HD 3510 with a working area of 29.8 x 18.5 x 20.3 cm, and printing the forms in the VisiJet material M3 X.

Thanks to 3D printing technology the firm can very quickly produce a nest shaping and begin the production of a new product. The printed material is additionally subjected to a hardening process that allows for the production of temperature-resistant molds or shaping inserts. The time needed for creating a product of this type lasts several hours, which significantly shortens the process of making the mold and starting the production of molded parts. What’s more, it also reduce the cost of production of the mold itself.

Comparing the traditional technologies of injection mold production to 3D printing technology, we can talk about a significant reduction of costs, which, in turn, impacts the profitability of new projects. Increased production capacities, speed of execution, and low costs could be the most important factors in the performance of short production runs of plastic injection molding.

Of course, molds made in this technology, in addition to the advantages I have already mentioned, have some drawbacks. First of all, they need good cooling. During production, it is essential to ensure stable temperature conditions. Additional cooling of the mold with compressed air after each injection is also recommended. But, overall, analyzing the market expectations, we can assume, that 3D printed injection molds may herald another technological breakthrough in the field of this production area.