Over 250 people gathered to participate in the 1st annual Windsor-Detroit Hacking Health event at TechTown Detroit on May 1-3, 2015. The event teamed up health care professionals, doctors, nurses, pharmacists, and hospital admins with professionals from the IT sector, programmers, and designers to design mobile solutions for the healthcare sector.

At the beginning o the event, it was obvious that the focus was clearly on mobile apps, and wearables. However, with the team of 3D printing designers from MakerOS, and some top notch 3D printers available, it didn’t take long before the shift of focus.

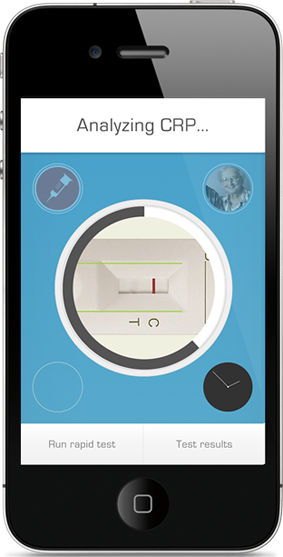

In addition to wearable devices being 3D printed, there was one project that really struck a cord. The project involved designing a harness for a mobile phone, to support it while it performed scans of a rapid diagnostic test. A rapid diagnostic test is cartridge or paper based test that typically responds to fluids such as blood, saliva or urine and creates a line if a positive results is present. Common examples include pregnancy, HIV, and malaria tests.

Background

On the global scene, two of the biggest problems with identifying and managing infectious diseases in developing countries are:

1) Unsatisfactory diagnosis and clinical management at the point of care and

2) Inadequate capture and transfer of point-of-care data to health program stakeholders for monitoring and evaluation (M&E), continuous quality improvement, and scarce resource management.

This problem is alleviated by a company called iSTOC and its mobile IDA Health platform, which works on certified Android and iOS devices. The IDA Health app is used by health care professionals to digitize tests at the point of care, and then transmit records of patient encounters to the iSTOC cloud web tool. The IDA app transforms the mobile phone into a diagnostic device that interprets commercially available RDTs for infectious diseases, such as malaria, HIV, syphilis, hepatitis, and dengue.

Shaking hand syndrome

The main challenge with using the IDA solution in the clinical setting is shaky hands and dealing with large volumes of tests. The phone must be correctly positioned during the RDT scanning process. Analysis of the data from field trials revealed that, although most scans were performed in less that 8 seconds, there were nurses and healthcare workers who were talking much longer. An evaluation recommended that a phone harness be made available to some locations, especially in developing countries, to automate the scanning of batches and assist people with shaky hands.

Hacking out a solution

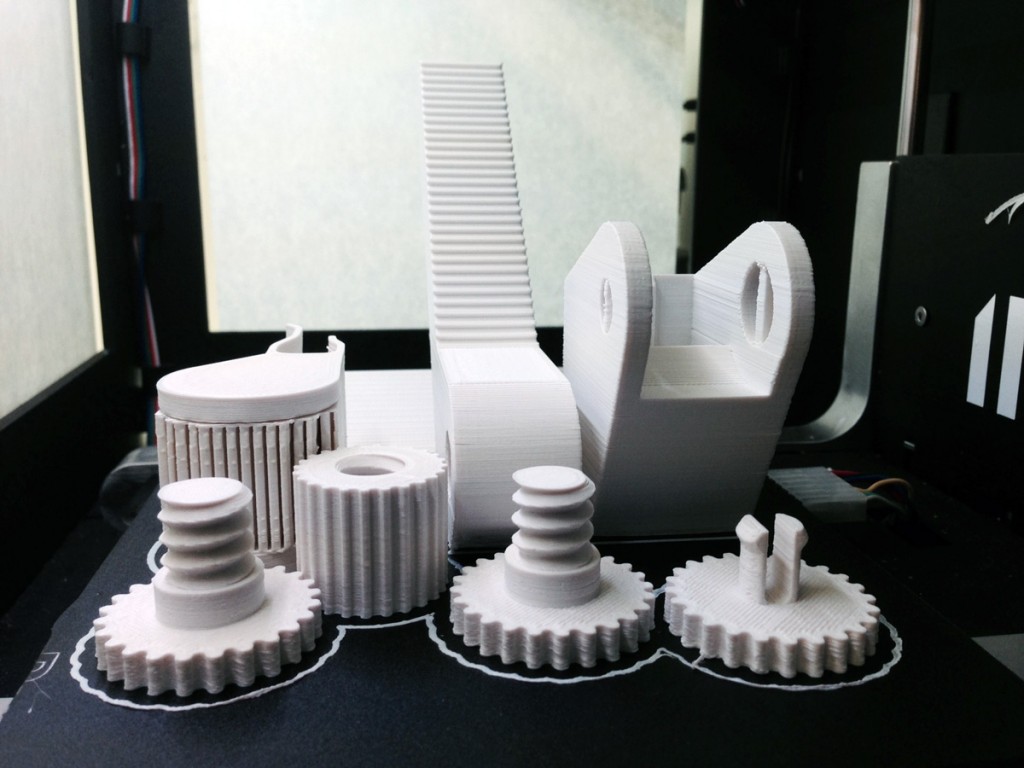

Fortunately, this problem was tackled at the Hacking Health event. The most important parameters were to create a 3D printable device that:

- Could hold a typical smartphone in existence now and in the future.

- Change angles between 10 – 35% to accommodate the various strip -scanning angles

- Adjust in height to support the autofocus.

- Have a base that could be adapted to different types of strips.

- Be easily 3D printed and assembled anywhere in the world, from Lagos to Mumbai, with easy-to-follow instructions.

It took one hour to discuss the options, and three hours to design the optimum solution. The solution was printed overnight and showcased at the demo session on the last day of the hackathon. It took 2 years to get to this point, and without the collaboration of the Hacking Health participants and the MakerOS team it would not be a reality.

The most compelling aspect of this solution is the ability to easily deploy the mobile phone harness solution anywhere in the world. With the propagation of 3D printing technology going global, we just send the 3D (STL) files to locations in a given locale. With the availability of software, such as the MakerOS advanced business management platform, it is becoming even easier for global Makers to start 3D printing businesses. MakerOS is a complete turn-key web application to manage clients, projects, financials.