Traveling nationwide in South Korea to report on those involved in the 3D printing industry, it is getting harder to become REALLY impressed by the variety of machines and firms out there, as things are moving so quickly and soon become obsolete. Contrary to my usual experience, however, I recently stumbled onto a firm that made my jaw drop. 3D LeeJo is a new 3D printing services company located in Changwon, South Korea.

I recently had a very pleasant visit to 3D LeeJo headquarters and met Mr. Lee Junghun, one of the founding members and also their chief planning officer. Before we sat down to talk, he gave us a tour of their factories, and, as we entered the first production room, we saw around 80 units of the same 3D printers, aligned and printing different items according to various customer requests. This room was only for ABS, and the room temperature was warm enough for ABS printing.

We then went around to the back of the building, where they had a temporary workspace set up, and they showed us another project that they were working on. For an upcoming exhibition, they were assembling a 4.5-meter-tall statue of Admiral Yi Sun-sin from hundreds of smaller pieces…sanding, gluing, and sanding again. For those not familiar with Korean history, Yi Sun-sin (1545–1598) was a Joseon Dynasty Korean naval commander, famed for his victories against the Japanese.

Across the parking lot, we visited another building which they had set up for PLA printing. We visited the printing center and also another office where several more professional 3D modelers and designers were busy at work. After our tour, we sat down in his office for an interview.

Q: Could your briefly introduce your firm?

Q: I would say that 3D LeeJo is probably the biggest 3D printing service provider in Korea. How has your company had such exponential growth in such a short time?

A: 3D LeeJo was officially established a year ago, but the company started as a combination of three people: the CEO Mr. Jo Seongjin, the CTO Mr. Kim Changhyun, and myself as the CPO. We met at a start-up center here in Changwon and found that we had a really good synergy. The CEO has been in sales for decades. The CTO had been exploring 3D printing for more than 10 years, and had been on a couple of TV shows as a 3D printer expert here in Korea. And I, myself, started as an engineer, and worked for three years in one of the large corporations in Korea, but quit to do my own business. I knew marketing was one field that I could excel at…so, basically, it started from there. We were all stationed in positions where we could maximize our talents; I think this really made things take off.

Q: I heard that your firm also has an online platform, could you tell me about that?

A: We have an online platform, ‘BonCreation’ (in Korean). It is a model printing platform similar to Thingiverse. It is a place where people can download designs, as well as upload them, too. We thought that, for the Korean 3D printing industry to grow, it was necessary to have a useful Korean-language site. Even though a large number of Koreans read and speak English, there are many more who do not. The site is not as big as we want right now, but we will encourage more people to join, and hopefully it will serve as a good community center for the exchange of information, as well as sharing 3D models.

Q: Recently, your firm won a commendation for its performance and contributions to society from the National IT Industry Promotion Agency (NIPA). Could you elaborate on that?

A: We heard an announcement that there would be an award competition where the winners would be announced at this year’s K-ICT 3D Printing Conference. We thought we were more than qualified to be one of the candidates, so we submitted our application. It has been a busy year, but, as a printing firm, we have demonstrated many of the possibilities of where 3D printing might go. We also were, and are, actively contributing to Korean society by creating more jobs and helping out other companies develop their own 3D printing projects. So, we applied, and were chosen. .

Q: As a printing firm, how do you calculate the printing prices for your customers?

A: For a single print, we can charge a flat rate of 5,000 Won (around $4.50 USD) per hour. It may sound a bit steep, but we charge much less for customers with a larger number of orders. For other services, such as modeling and post-processing, it really is hard to standardize the cost, since every request is different depending on a customer’s needs. So, it goes case by case. But, most times, we find our prices are quite reasonable and our customers are satisfied.

Q: As the firm grows, is there any chance that you will expand to overseas markets?

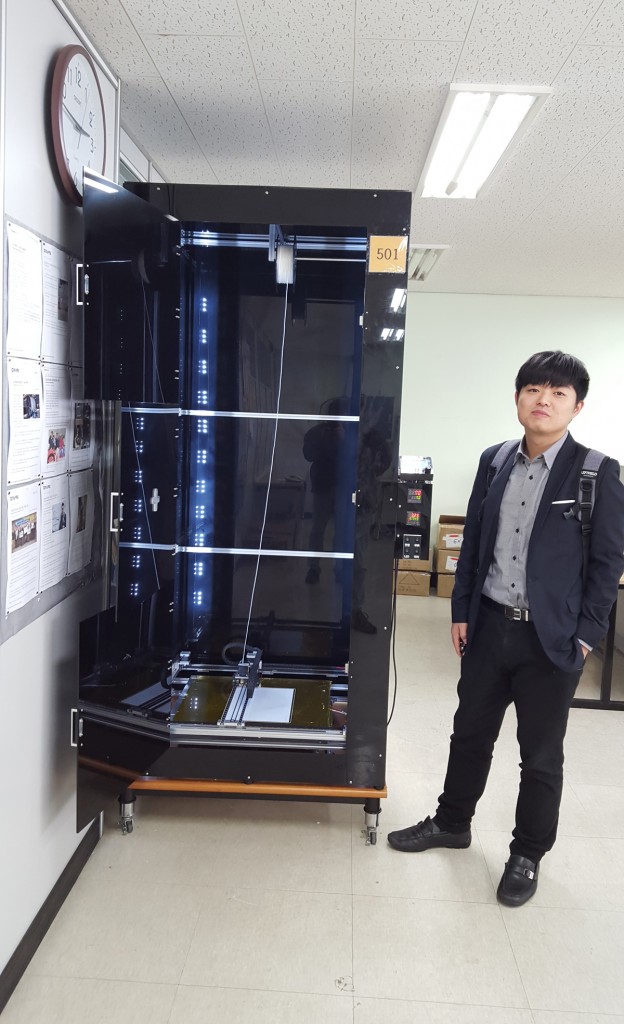

A: We definitely do plan for that in the future. For now, we are preparing for the selling of our printers overseas, rather than providing printing services in other nations. We have manufactured three types of printers; the BonBot E200 desktop, and the BonBot I200 and I300, which are industrial machines. In the domestic market, we sell in lots, usually around 20 units per order. Once we sell our products, we help our customers run them by sharing our operating or managing systems, which helps prevent any problems with the printers in the future. For the overseas markets, we plan to sell big printers that we are currently testing now. The build volume of these new machines will be either 1 meter x 1 meter x 1 meter or bigger. The machine you saw in our lab was a prototype that had a build area of 500cm x 500cm x 1.5 meters. Our bigger machines will be FDM machines, but utilize different sizes and types of nozzles. Also, rather than using filament, they will use pellets which would be fed into them from a funnel-shaped hopper, like an injection molding machine. We will probably start in Asian countries like Japan first, and slowly expand to different nations.

Q: Anything to add, or any last words before we finish this interview?

Not really. I just want people to pay attention to our firm, 3D LeeJo. There are lots of printing companies in the world, but we have not seen many that have the vision or capabilities that we do. We are dead serious about our business, and want to become the best printing firm possible. That is it. Thank you.